You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

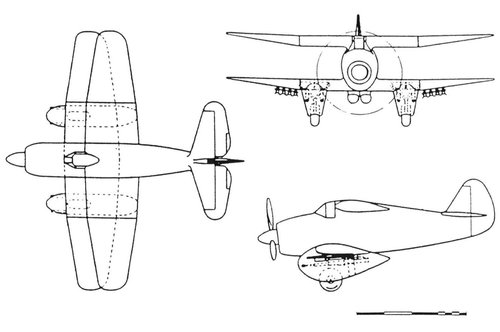

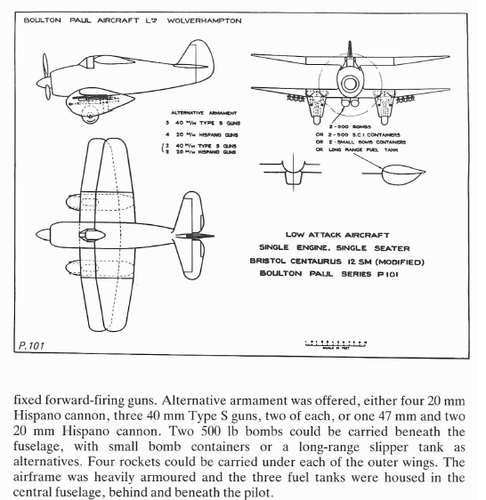

Boulton Paul P.101. Weapon options.

- Thread starter Tim52413

- Start date

Thanks, but I you about location of 3 guns on the plane.From Putnam's book.

- Joined

- 25 July 2007

- Messages

- 4,299

- Reaction score

- 4,196

How can 3 40-mm Type S guns be mounted on Boulton Paul P.101? ...

The fixed armament for the Boulton Paul P.101 was to be mounted in the spats. So, likely, an asymmetric layout with one Vickers Type S in one spat and twin S guns on either side of the opposite spat. That same layout would probably have followed for the other asymmetric armament option of 1 x 40 mm + 2 x 20 mm.

- Joined

- 28 January 2008

- Messages

- 635

- Reaction score

- 511

The recently re-released Alec Brew BP book states:

"The large spats that housed the undercarriage also held the guns, either four 20-mm, three 40-mm or one 47-mm and two cannon. Two 500 lb bombs could be carried beneath the fuselage, with eight rockets under the wings. The airframe was heavily armoured."

Source: Boulton Paul Aircraft Since 1915 (Alec Brew) Fonthill 2020 (ISBN 978-1-78155-751-8)

"The large spats that housed the undercarriage also held the guns, either four 20-mm, three 40-mm or one 47-mm and two cannon. Two 500 lb bombs could be carried beneath the fuselage, with eight rockets under the wings. The airframe was heavily armoured."

Source: Boulton Paul Aircraft Since 1915 (Alec Brew) Fonthill 2020 (ISBN 978-1-78155-751-8)

Aubi

ACCESS: Secret

That really says nothing new. Where was the odd 40 mm cannon? Were two cannons on one side and one on the other side?

- Joined

- 26 May 2011

- Messages

- 2,318

- Reaction score

- 3,472

That really says nothing new. Where was the odd 40 mm cannon? Were two cannons on one side and one on the other side?

That's why they build mock-ups. This is a paper study. No mock up was built as far as I could see.

It is covered in Typhoon to Typhoon.

Chris

- Joined

- 25 July 2007

- Messages

- 4,299

- Reaction score

- 4,196

Hm. Could one of 40-mm autocanons has a synchronizer for firing through propeller?

No reason that a synchronization gear couldn't have been introduced. The engine for the P.101 was a Bristol Centaurus 12SM (Mod) ... raising the question: what was the '(Mod)'?

The thing is, there's no evidence that what could be done was actually being considered at Pendeford. Until someone finds a reference to JD North planning for synchronization, we have to assume that Cy-27's Alec Brew quote means that all guns were housed within the spats.

Synchronisation became more problematic as ammunition size increased. The Luftwaffe adopted the high-velocity 30mm MK 103 cannon with electrical ignition as this made it more suitable for synchronisation, but they found that the burning rate of the large quantity of propellant was too variable to give consistent timing, so there was a significant risk of hitting the propeller - not something you want to do with a 30mm shell!

blackkite

Don't laugh, don't cry, don't even curse, but.....

- Joined

- 31 May 2007

- Messages

- 8,819

- Reaction score

- 7,716

Attachments

- Joined

- 27 December 2005

- Messages

- 17,748

- Reaction score

- 26,421

Hm. Could one of 40-mm autocanons has a synchronizer for firing through propeller?

No reason that a synchronization gear couldn't have been introduced. The engine for the P.101 was a Bristol Centaurus 12SM (Mod) ... raising the question: what was the '(Mod)'?

The thing is, there's no evidence that what could be done was actually being considered at Pendeford. Until someone finds a reference to JD North planning for synchronization, we have to assume that Cy-27's Alec Brew quote means that all guns were housed within the spats.

Agreed, the available evidence is the weapons were intended to be in the spats.

I should add that the 20mm Hispano was unsuitable for synchronisation anyway (except for the post-WW2 electric-primed US version).

- Joined

- 11 March 2012

- Messages

- 3,249

- Reaction score

- 3,179

I can't see why an asymmetric layout would be any particular problem. Am I missing something?

If you mount the heaviest gun near the centre-line, not a big deal.

OTOH if you only mount a single heavy gun in a sponson, firing it will turn the airplane away from the target.

- Joined

- 11 March 2012

- Messages

- 3,249

- Reaction score

- 3,179

I should add that the 20mm Hispano was unsuitable for synchronisation anyway (except for the post-WW2 electric-primed US version).

Yes Tony,

Both the Oerlikon FF and Hispano-Suiza fired from open bolts, meaning a long time between pulling the trigger and the bullet exiting the muzzle. That longer "lock time" made them more difficult to synchronize with rotating propellers.

Both 20 mm cannons used advanced primer ignition, blow back actions. The bolt was held back to the rear after every shot. This left the chamber open to cooling air. Pulling the trigger released the bolt to slide forward and chamber a cartridge. Just before the bolt reached its full-forward position, the firing pin struck the primer, igniting the primer and main propellant charge (gun powder). The bolt never locked closed. Since the bolt was still travelling forward, the propellant had to stop the bolt's momentum before the bolt could begin its recoil stroke. This allowed for a lighter gun.

The same advanced primer ignition is used in most (pistol calibre) sub machine guns and some modern artillery pieces, again to simplify and lighten breech mechanisms.

Last edited:

- Joined

- 19 October 2012

- Messages

- 1,984

- Reaction score

- 1,941

Apparently the surviving B-P project document is vague on this point although it does state that all guns were to mounted outside of the propeller arc.

The Oerlikon did, but not the Hispano - that used a hybrid gas-unlocked blowback. It fired from an open bolt (which is why it couldn't be synchronised, as you rightly say) but the bolt was closed and locked before firing. Gas tapped from the barrel then unlocked the locking flaps, allowing the gas pressure in the barrel to push the bolt back and blow the fired case out of the chamber.Both 20 mm cannons used advanced primer ignition, blow back actions.

The API blowback mechanism became obsolete decades ago, but a lot of automatic cannon utilise floating firing, aka soft or differential recoil mountings. In this case, the gun (that is, the entire barrel and gun action) is held to the rear before firing; pressing the trigger releases the gun to run forwards under spring pressure until it is nearly all the way forward, at which point the gun fires. So the recoil has to halt the forward momentum of the gun before driving it back again. This has the effect of smoothing out the recoil pulses, considerably reducing the peak recoil kick.

I can't see why an asymmetric layout would be any particular problem. Am I missing something?

If you mount the heaviest gun near the centre-line, not a big deal.

OTOH if you only mount a single heavy gun in a sponson, firing it will turn the airplane away from the target.

Well, yes, obviously. But, in one way or another, the problem can be compensated for if the asymmetry serves other goals. It's a matter of competing design constraints, not an absolute.

After all, you can hardly count on two guns firing at the exact same moment, given feed problems, small variations in individual rates of fire, misfires, variations in ammunition, etc. Wing-mounted guns were always a compromise between accuracy and fire density on the one hand and the propeller on the other.

I should add that the 20mm Hispano was unsuitable for synchronisation anyway (except for the post-WW2 electric-primed US version).

Yes Tony,

Both the Oerlikon FF and Hispano-Suiza fired from open bolts, meaning a long time between pulling the trigger and the bullet exiting the muzzle. That longer "lock time" made them more difficult to synchronize with rotating propellers.

Both 20 mm cannons used advanced primer ignition, blow back actions. The bolt was held back to the rear after every shot. This left the chamber open to cooling air. Pulling the trigger released the bolt to slide forward and chamber a cartridge. Just before the bolt reached its full-forward position, the firing pin struck the primer, igniting the primer and main propellant charge (gun powder). The bolt never locked closed. Since the bolt was still travelling forward, the propellant had to stop the bolt's momentum before the bolt could begin its recoil stroke. This allowed for a lighter gun.

The same advanced primer ignition is used in most (pistol calibre) sub machine guns and some modern artillery pieces, again to simplify and lighten breech mechanisms.

I am not a firearms expert. But I thought the issue with synchronizing these weapons had less to do with the open bolt than the nature of blow-back (Oerlikon/MG FF) or hybrid blow-back/locked (Hispano) actions.

Both blow-back and locked-breach firearms can use either an open bolt or a closed one. For example, military Uzi submachines guns use an open-bolt action. But I have read that civilian, semiautomatic models for the US market were re-engineered to use a closed bolt.

Open breaches are typical of fully automatic weapons because the extra chamber cooling reduces cook-off (which would probably be especially undesirable in a synchronized gun, now that I think of it).

An open breach will indeed take longer to close than a closed bolt. But, in a locked breach design, the delay will be reliably constant, because it is mechanically controlled.

The delay can be highly variable in a blow-back weapon, however, whether or not thefiring cycle begins with an open or closed breech, because the cycle time for blow-back weapons depends on the cartridge rather than the breech. The cycle time of a locked breech is determined by the mechanics of the lock, while that of the blow-back design depends on the combustion of the cartridge propellant and the consequent pressure rise in the chamber, both of which are inherently variable.

The only relatively successful synchronized blow-back weapon I have heard of was the 8-mm Austro-Hungarian Swarzlose (sp?) machine gun of WW1. Late in the war, synchonized versions appeared on some fighters (earlier, they were carried over the wing in a distinctive "baby coffin" wood-and-aluminum fairing). But the gun was used because it was the standard army gun and thus all that was available, not because it was a good solution for aircraft use. Propellers did get shot up, and at lest some pilots continued to prefer the old over-wing arrangements.

Last edited:

Can the third 40-mm canon be mounted in top wing (above the cockpit)?

It doesn't look like it was in the sketches. But even if it were, the gun would still fire off-axis because of the propeller's diameter. Besides, if asymmetry on firing were indeed a problem, this possibility might make things worse, as well, since recoil would induce pitch up as well as yaw, even if the yaw were reduced by placing the gun closer to the centerline.

I am not a firearms expert. But I thought the issue with synchronizing these weapons had less to do with the open bolt than the nature of blow-back (Oerlikon/MG FF) or hybrid blow-back/locked (Hispano) actions.

Both blow-back and locked-breach firearms can use either an open bolt or a closed one. For example, military Uzi submachines guns use an open-bolt action. But I have read that civilian, semiautomatic models for the US market were re-engineered to use a closed bolt.

That is correct - but there is a huge difference between pistol ammunition and cannon. In pistols, .380 calibre (9x17) is generally regarded as the maximum power which can safely use simple blowback (from a closed bolt). In SMGs more powerful pistol ammo can be used, because the heavier bolts required are more acceptable. It is the inertia of the bolt which provides the delay in the breech opening (the spring has a secondary effect), and as the power of the cartridge goes up, so must the bolt weight. Chinn calculated that if a 20 mm Oerlikon cannon fired from a closed bolt rather than using API, the bolt would have to weigh ten times as much. That would bring the rate of fire right down, and mean that if the gun was elevated to fire at aircraft, the bolt would probably slide backwards, compressing the recoil spring and preventing the gun from firing at all.

Open breaches are typical of fully automatic weapons because the extra chamber cooling reduces cook-off (which would probably be especially undesirable in a synchronized gun, now that I think of it).

An open breach will indeed take longer to close than a closed bolt. But, in a locked breach design, the delay will be reliably constant, because it is mechanically controlled.

The delay can be highly variable in a blow-back weapon, however, whether or not thefiring cycle begins with an open or closed breech, because the cycle time for blow-back weapons depends on the cartridge rather than the breech. The cycle time of a locked breech is determined by the mechanics of the lock, while that of the blow-back design depends on the combustion of the cartridge propellant and the consequent pressure rise in the chamber, both of which are inherently variable.

I can't agree with most of that, except for the need to avoid cook-offs - and the only way to ensure that is to fire from an open bolt. A huge amount of ingenuity went into trying to synchronise open-bolt weapons, most specifically for the Lewis MG in WW1. An extract from my web article on synchronisation:

At first, Allied efforts were hampered by the preference for using the Lewis and Hotchkiss Aviation guns, so much lighter than the Vickers-Maxim type. However, the mechanism of these guns was fundamentally unsuited to synchronisation as there was no positive firing pin release; they fired from an open bolt, the primer being struck automatically as the breech closed. On receiving the firing signal, the bolt was released to move forwards under spring pressure, pushing a cartridge from the ammunition feed and into the chamber, and then locking the bolt before the gun could fire. The time delay between the pilot pressing the firing button and the first shot being fired was far too long for the accurate timing required.

For effective synchronisation the time between the firing signal and the moment when the projectile leaves the barrel (the lock time) is crucial. Because the propeller rotates over an important angle during this interval, this time needs to be accurately controlled. It also needs to be as short as possible, because the rotation speed of the propeller itself is not constant but dependent on engine rpm, and the longer the lock time, the greater the variation in propeller travel. Little progress with synchronisation was made until the Vickers-Maxim guns, which happened to have a positive striker release and fired from a closed bolt, was modified for the purpose; the lock time was much shorter, about one-twelfth that of the open-bolt types.

The only relatively successful synchronized blow-back weapon I have heard of was the 8-mm Austro-Hungarian Swarzlose (sp?) machine gun of WW1. Late in the war, synchonized versions appeared on some fighters (earlier, they were carried over the wing in a distinctive "baby coffin" wood-and-aluminum fairing). But the gun was used because it was the standard army gun and thus all that was available, not because it was a good solution for aircraft use. Propellers did get shot up, and at lest some pilots continued to prefer the old over-wing arrangements.

Another extract from my synchro article:

The Austro-Hungarians had to develop synchronisation gear suited to work with the Schwarzlose retarded blowback gun. The Zaparka gear fired the gun on every fourth propeller revolution, and the quoted rate of fire (RoF) dropped from 590 to 380 rounds per minute (rpm) for the M16 or from 880 to 500 rpm for the M16A. The mechanism could be relied on only within a band of engine revolutions between 1000 and 1600 rpm with the M07/12, and 600 to 1600 rpm with the MG 16. This explains the very prominent place given in the cockpit of fighters to a large engine tachometer. The Bernatzik and Daimler gear reduced the RoF even more, by 55% in the case of the M16. However, the Daimler gear did have the advantage that the M16 could be safely fired from engine idle to 1600 revolutions per minute, although the M07/12 was still restricted to a 1100 – 1600 rpm band. At the end of the war the Austro-Hungarian forces decided the standardise on the Priesel system.

Similar threads

-

-

Boulton Paul P.41 Phoenix and Phoenix II

- Started by cluttonfred

- Replies: 2

-

-

Short S.34 and Super Stirling proposals

- Started by Apophenia

- Replies: 11

-