C O N V A I R

F-102 Project History

In 1950, the Air Force decided it was necessary to develop a high altitude supersonic airplane and issued invitations to bid to a number of U. S. aircraft manufacturers.

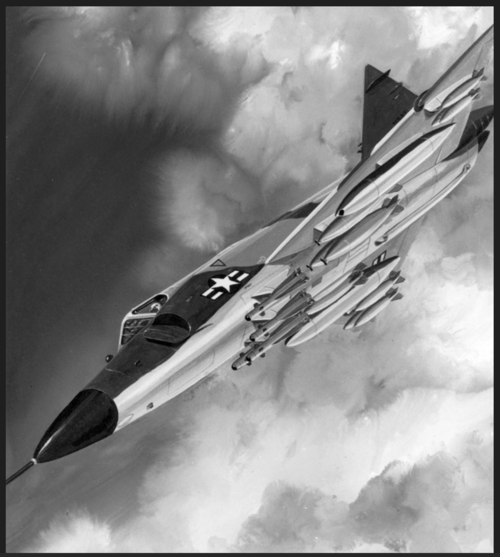

In January 1951 Convair entered the design competition by submitting its specifications on a delta wing, jet propelled aircraft which is now known as F-102A.

Convair, whose design was deemed the most desirable for the F-102 Project, was selected to carry out phase I of the development program.

In August of 1951, Convair entered into a contract for the F-102 and a letter of contract was received.

The Air Force established a new plan for the flight test development of new airplanes such as the F-102. This plan was identified as the Accelerated Develop ment Test Program and called for the use of the two prototype models and the first 40 production models to carry out all phases of development testing which had heretofore been carried out by a maximum of 6 airplanes on most test programs. This new approach to flight testing was caused primarily by the facts that, (a) The advent of supersonic flight required an almost total reinvestigation of all established flight criteria, and (b) The Accelerated Development Test Program plan shortened the development of a new airplane by a substantial period of time, thereby making new airplanes available to the defense system at an earlier date.

The tooling plan set forth by the Air Force called for tooling to produce ten airplanes per month, but that this tooling be of a type and quality for efficient production of fifty airplanes per month. A Convair counter proposal was submitted which called for a progressive tooling policy since it was realized that the Air Force intended to ultimately expand the tooling to accomodate a production rate of 50 airplanes per month and higher. This tooling policy was based on using the actual production rate of 3 airplanes per month, but of a type of tooling based on a maximum rate of 125 per month. Negotiations for a facility site were completed and the acquisition of Plant II obtained.

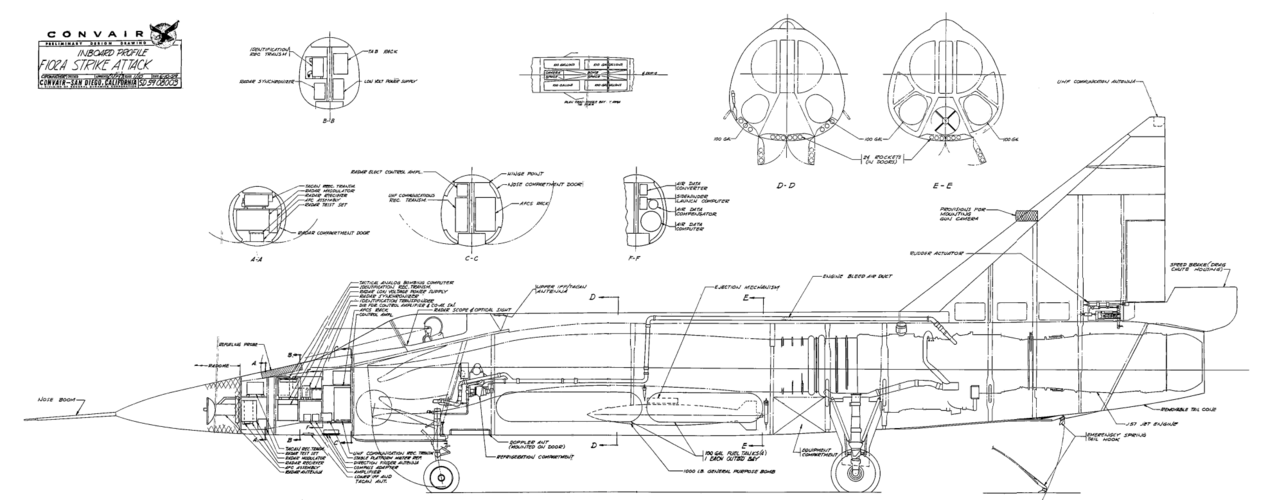

Some of the Engineering problems involved included the development of a newly designed aircraft around a new engine that was still in the design stage.

Planning and Tooling peculiarities involved in the production of this high speed aircraft involved the aerodynamics surface tolerances and contour control requirements which are inherent to supersonic aircraft.

Generally accepted surface irregularities as found in conventional aircraft were prohibitive in the F-102 airplane.

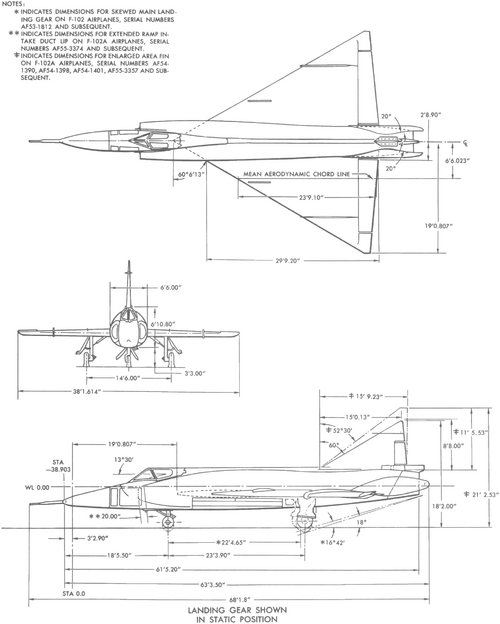

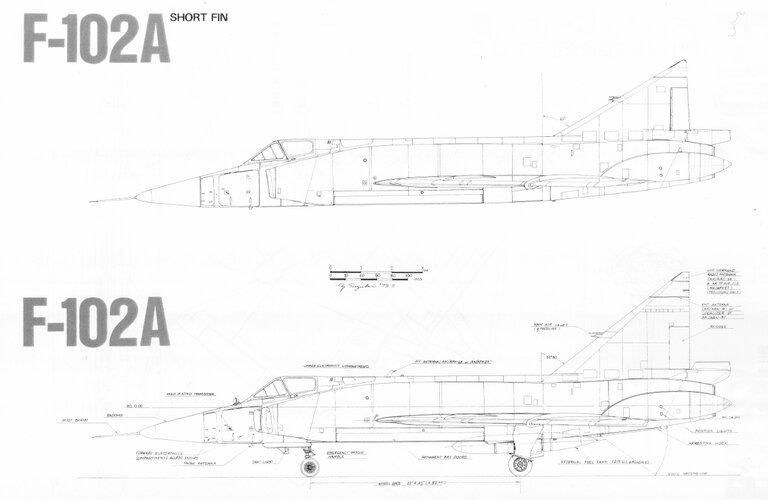

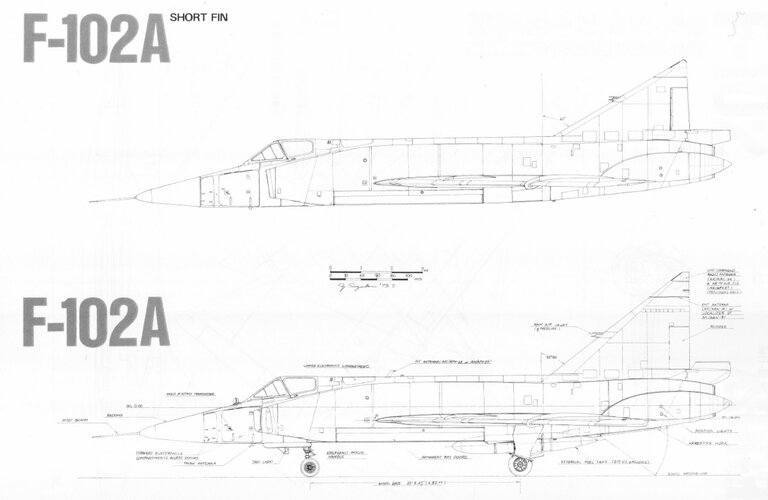

The advent of supersonic flight introduced many problems relative to the design of supersonic vehicles, and, since a great deal of the design criteria for super sonic vehicles was based upon theory and calculation with no specific flight experience to substantiate the theory, it has been necessary for both industry and the Air Force and Navy to revise their approach to various aircraft designs from time to time as the state of the art progresses. In this connection, a joint decision on the part of the Air Force and Convair was made to introduce a modified F-102 fuselage, wing tips and wing leading edges as a result of the gradually expanding learning curve relative to supersonic flight, which was constantly being expanded as a result of the national and international effort being made to over come the obstacles leading to general standardization of aircraft design for supersonic flight.

As the results became known of the tests conducted of pre-flight models in the transonic and supersonic ranges in June of 1952 by NACA (National Advisory Committee on Aeronautics) at Langley Field in Virginia, Convair pre-design Engineers felt that the theory of cross sectional area versus fuselage length had a great amount of practical application in a redesign of the then present 8-82

configuration.

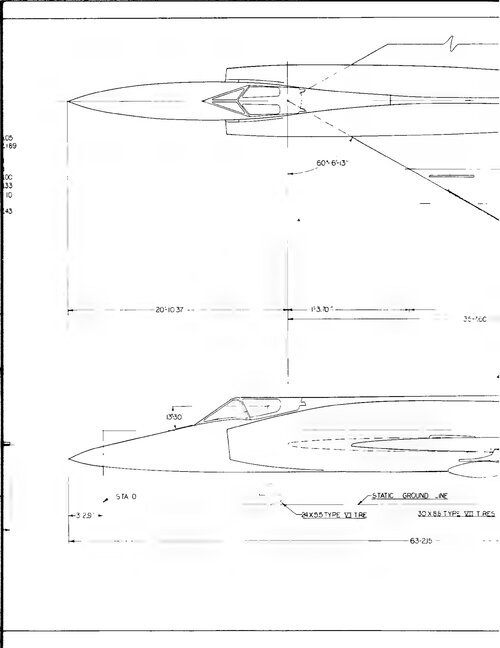

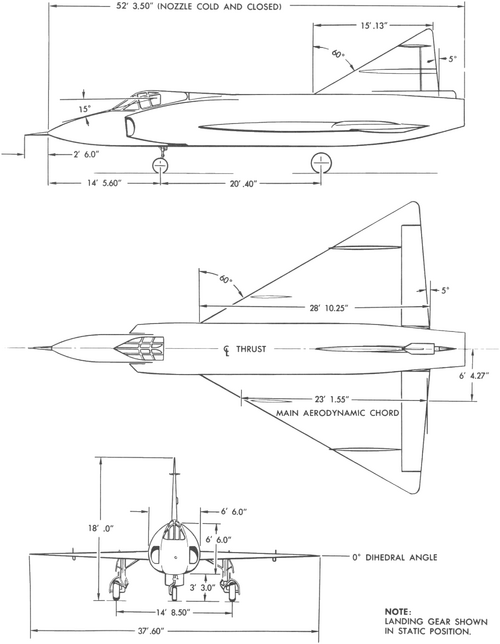

With the completion of the first HARD model tests as well as more complete tunnel tests initiated in the interests of drag reduction, it became apparent that the then present fuselage configuration drag could be reduced appreciably by incorporating a "Waisted" body idealized from the "Area-Rule Concept". This established an improved configuration involving an approximate 7 foot extension to the rear end of the fuselage with a corresponding movement of the vertical tail, and an approximate 39 inch aft movement of the wing to maintain balance. The performance gains with the J-57 engine in the transonic speed range and in high speed at altitude were sufficient to warrant serious consideration of a change in the F-102 configuration as early in the production program as was feasible. Since this change would have appreciable effect on the Flight Test program as well as upon production schedule, this subject was reviewed with all affected Air Force agencies in an effort to obtain a decision as to whether this change should be incorporated in the F-102 airplanes. It was decided that this change, despite its possible effect on production rate in the early months of its incorporation, would not have any adverse effect on the then present concept of tactical operating groups in early 1956. Although this change was of a major nature in view of the configuration changes involved, it had been established through predesign that development of the Fire Control System as well as other functional systems of the airplane would not be jeopardized since the performance and aerodynamic characteristics of the two configurations were sufficiently similar in design.

Management decision to convert to the " Ideal Body" was formulated in August of 1953, (Sales Order 33-l-S2A) and preliminary design was completed, incorporating integral ducts of which a portion would be suitable for J-57 , J-67 or J-75 engines.

Construction of the 1/9 scale flutter models were completed in October of 1953 and changes were incorporated to determine the effect of cambered leading edges and reflex tips . The first configurations had boundry layer bridging across two ramps, causing unpredifcted shock patterns with a strong vortex sheet entering the inlet . The resulting pressure recovery was considerably low er than predicted.

Replacement of the precompression ramp eliminated this bridging and with this configuration the pressure recovery approached the estimated value within 2%.

Testing was now complete.

A CCN (N-93912) was received in late October of 1953.

Preliminary design for the incorporation of the production design started in late August of 1953.

Due to the short span of time established for delivery of this redesigned airplane (December 1954), special expediting of the whole program had to be planned.

On-Board Planning was established to maintain contact with all Engineering groups for the purpose of obtaining advance in formation of changes.

Tool Design was to use and rework as many of the existing tools and fixtures as were feasible .

Production shops were to work to a condensed schedule build in g sub-assemblies in to larger components or directly in to the airplane .

Special expedite action had to be established on outside purchased parts that were long lead time development items.

Detail design for the #1 prototype was started in April of 1952 and completed in April of 1953. Fabrication and assem bly were s ta r te d in July of 1952 and the #1 prototype airplane was completed in October of 1953 and shipped to Edwards Air Force Base a t Muroc, California.

Flight testing reached six flights during October. The quality of the airplane handling characteristics and performance follow ed close to predicted figures . On November 2, 1953, the airplane was lost during a take-off on Flight #7.

The #2 prototype at this time was well along in production . This was rushed to completion and delivered to Edwards Air Force Base on the 14th of December, 1953.

The first high speed taxi tests and a half mile lift off was accomplished on 31 December 1953. The initial flights that followed after the first of the year 1954 consisted primarily of successive incremental increases in speed as permitted by in flight flutter vibration tests.

The airplane was grounded after Flight #9 due to malfunction of the engine and to rework the air in take ducts.

This work, is now in process and nearing completion. Flight testing is scheduled to resume on the weekend of 28 February.

Present Status

Of approximately 568 EWO’s on the new body configuration , 149 have been final released as of this date . This amounts to approximately 25% of the total design release on the new body style.

On-Board Planning has written and issued tool orders in the amount of 5502.

Production orders now in the system peculiar to the 8-90 model amount to 1924.