1964: Year of Decision for the Strategic Force of the 1970s

By

J. S. Butz Jr.

Dec. 1, 1963

Within the Air Force the feeling has long been clear that the mixed force is necessary. A new manned bomber, to replace the aging B-52 force, is therefore a requirement.

Three systems are presently under study and in competition with one another to fill the advanced bomber role in the 1970s:

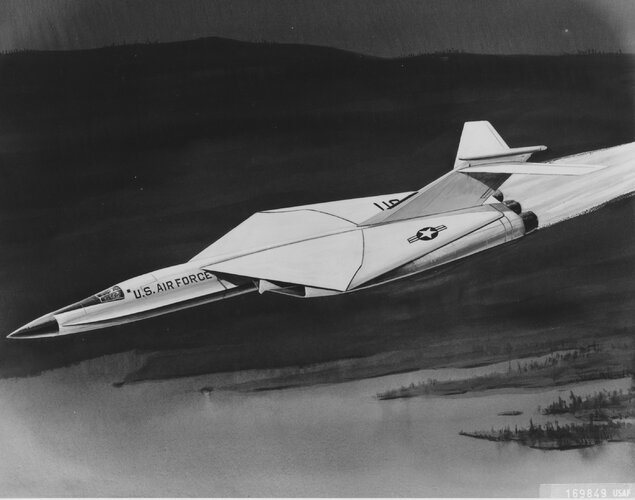

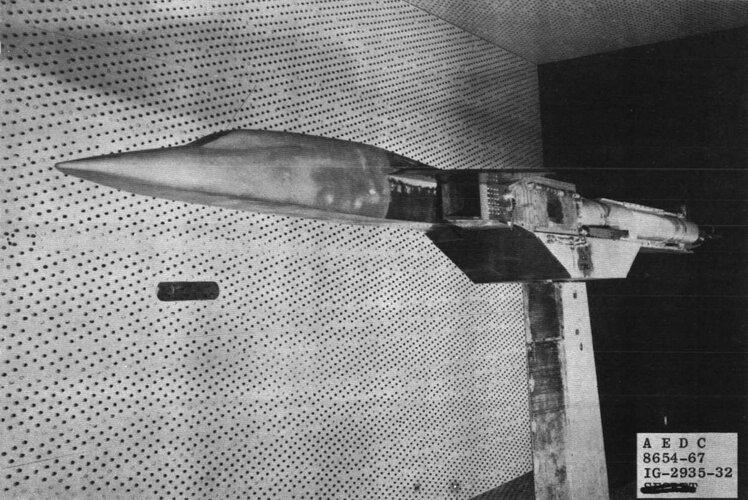

• A high-altitude, extremely-high-speed reconnaissance/strike aircraft.

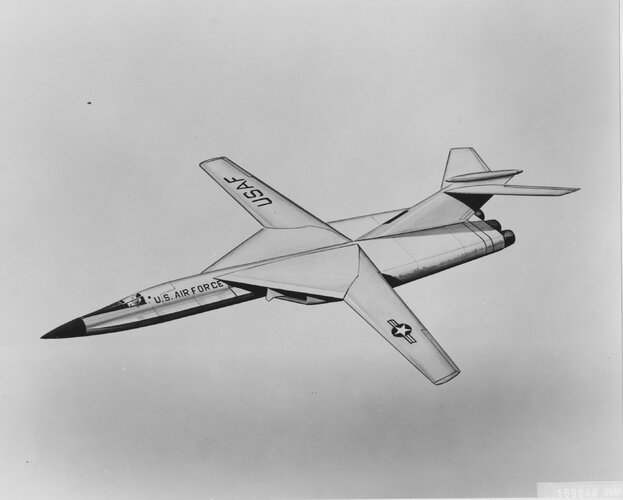

• An advanced manned penetrator with variable-sweep wings—one that would attack at low level and high speed.

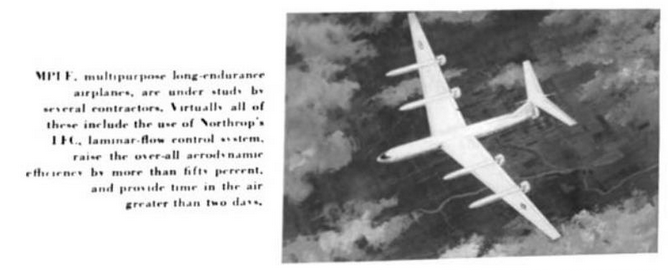

• A multipurpose, long-endurance aircraft, probably using laminar-flow control and regenerative turboprop engines.

....

Three Systems Under Study

In the final round of briefings and discussions with the OSD, the Air Force is basing its case for the manned strategic bomber primarily on three detailed systems studies which are due to be completed next spring. These study aircraft which are in competition for the advanced bomber role concern:

•

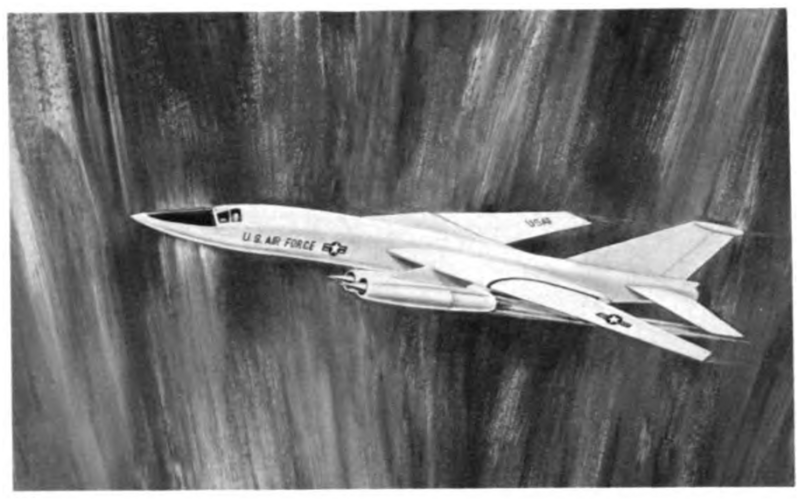

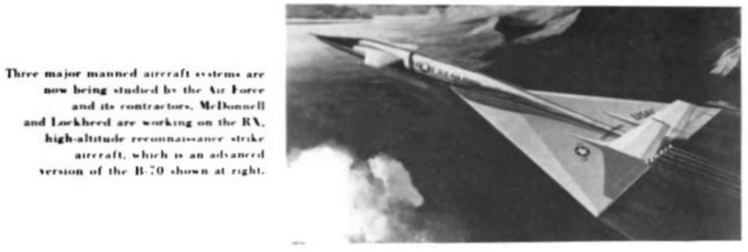

High-altitude, extremely high-speed reconnaissance/strike aircraft. McDonnell Aircraft Corporation and Lockheed Aircraft Corporation are both engaged in USAF-sponsored studies of this type of vehicle which currently is called the RX.

•

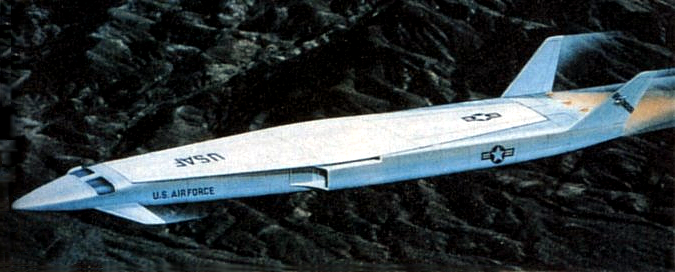

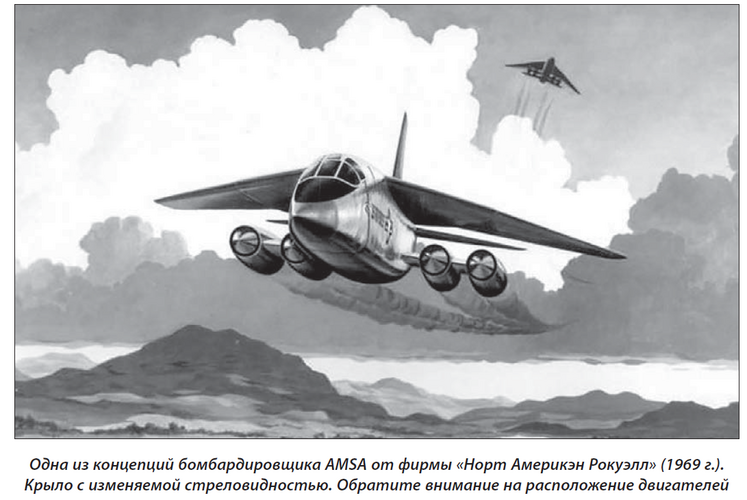

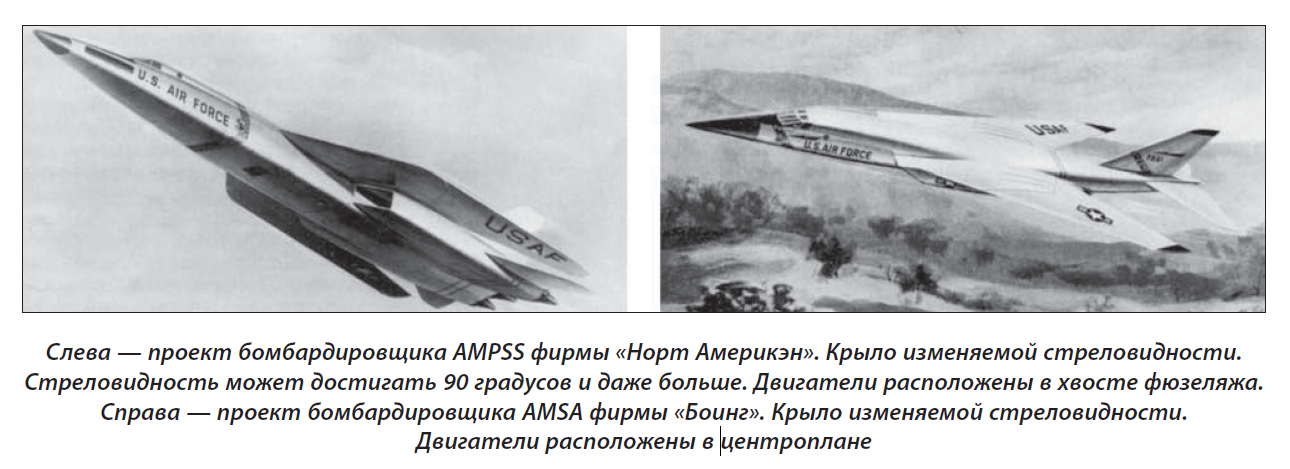

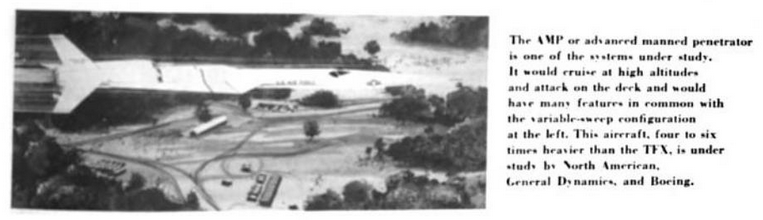

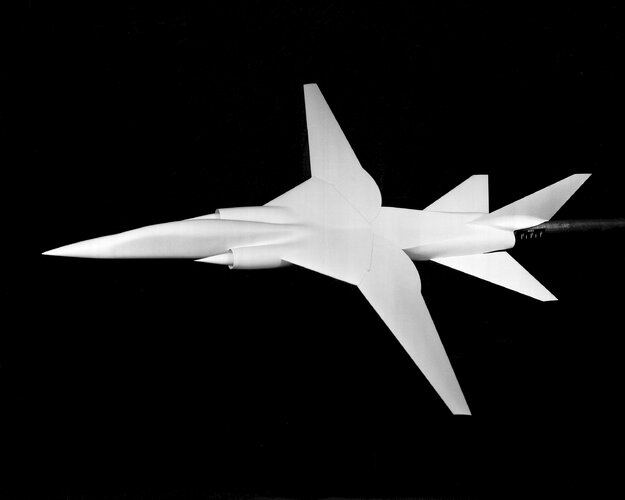

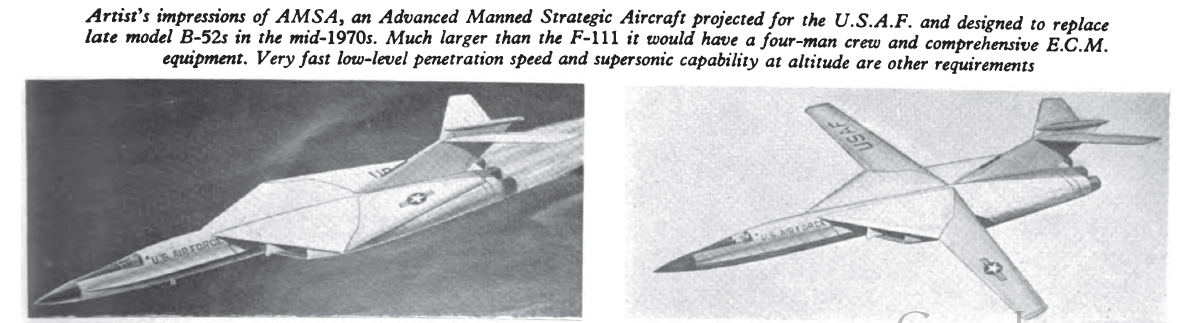

Advanced manned penetrators (AMP) which would cruise out at high level and fly at low level and high speed during the last few hundred miles to the target. This aircraft undoubtedly would need variable-sweep wings for it is to perform essentially the same mission as the TFX but stretched to intercontinental ranges.

This capability for high speed on the deck should enable this aircraft to cruise continuously at supersonic speeds at altitude with little performance penalty in other areas. General Dynamics Corporation, the Boeing Company, and North American Aviation, Inc., are conducting such studies.

•

Multipurpose, long-endurance aircraft called MPLE or Maple. A wide variety of these multiple-purpose aircraft is possible, and they seem adaptable to several other tasks in addition to the strategic. Endurance versus speed appears to be the most important trade-off. For instance, if several days of endurance are provided, the aircraft probably would have to be driven by regenerative turboprop engines turning very-large-diameter propellers. If more speed were desired, turbofans or turbojets would be used, and the propulsive efficiency and endurance would drop. A major strategic advantage of the very-long-endurance Maple is that it could circle existing air defenses and could approach the Eurasian land mass from any direction with air-launched missiles. Several companies are working on studies of this type, with virtually all of them using the Northrop-developed laminar-flow control, low-drag boundary-layer control system.

All of these design studies are of the parametric kind and investigate the influence of a wide variety of factors on the performance and effectiveness of each type of aircraft. For instance, the advantages and disadvantages of aluminum, titanium, and steel structure and turbofan versus turbojet powerplants are looked into in detail. Variations of each type of engine and structure also would be studied, with each variation pushing the “state of the art” a little differently—or not pushing it at all.