Dagger

ACCESS: Secret

- Joined

- 24 December 2019

- Messages

- 335

- Reaction score

- 623

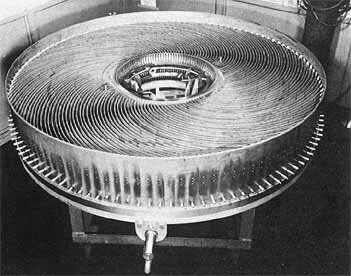

That was exactly my point: tubular heat exchangers with small diameter tubes are nothing new or special.Tubular heat exchangers with small diameters are beeing used quite succsessfully in racecars, millitary vehicle and some aircraft applications:It's just a tubular heat exchanger.

Tubular heat exchangers are the most common heat exchangers in the world, already for many decades. They are available in various sizes and shapes from many heat exchanger companies.

..........................................................................

Mezzo Microtube Heat Exchangers - Mezzo Technologies

Explore Mezzo Technologies' expertise in engineering custom microtube heat exchangers for extreme performance. Our accountable, technically advanced team pioneers innovation in thermal management, delivering lightweight, aerodynamic solutions for diverse industries.www.mezzotech.com

..................................................................

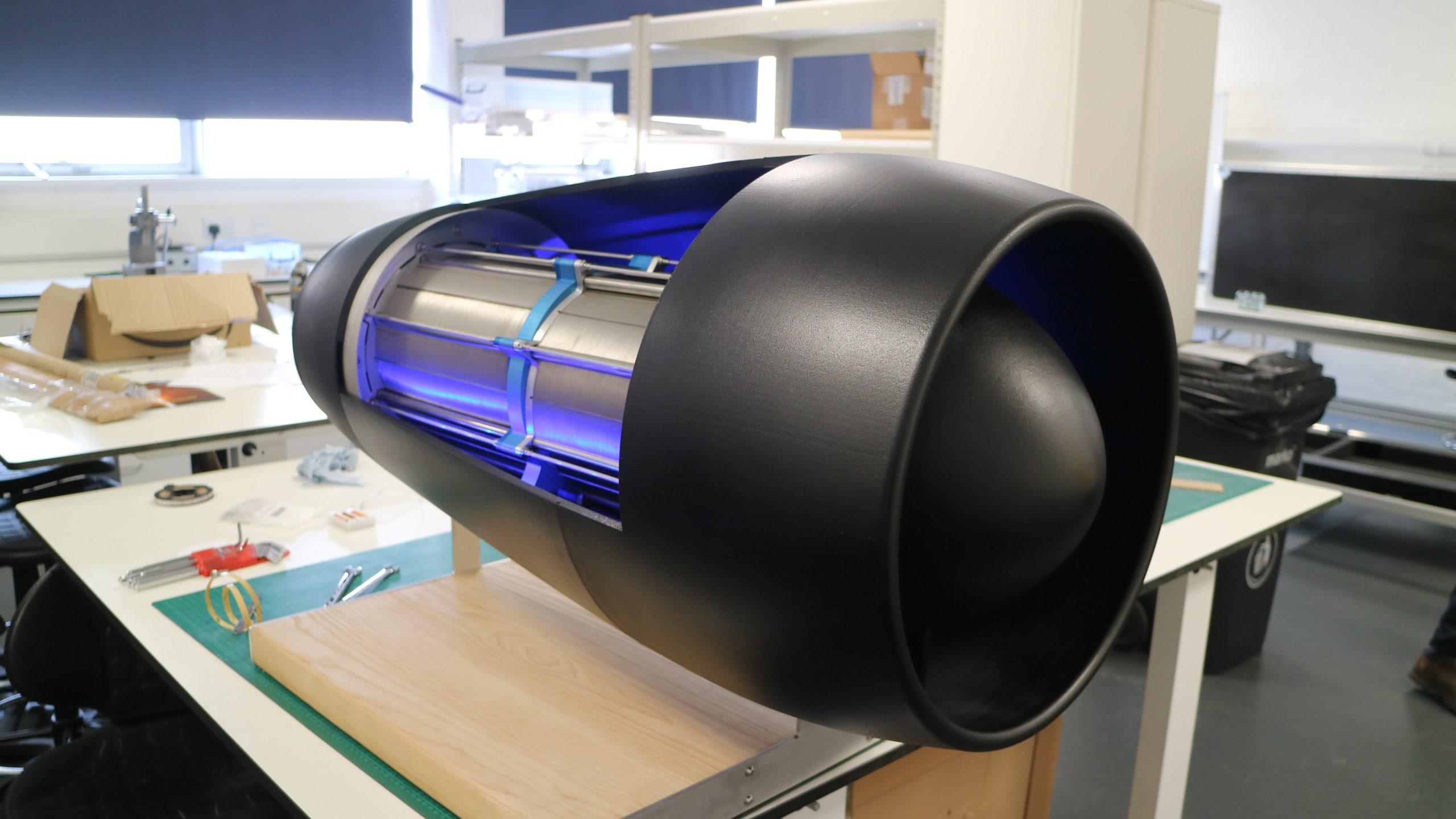

A couple of years ago REL changed their logo into a cross section of the precooler:..............................................

.............................................

And finally no, Reaction Engines limited was never established to develop Skylon, there’s a clue in their name which should be very obvious.

There's a clue in this new logo which should be very obvious: they are a heat exchanger company.

In the past REL definitely talked a lot about Skylon but since the dreamers retired it is hardly mentioned anymore, and if it is it's about flying to Sidney in four hours instead of flying into space. Hence they don't talk about cooling air to -150 oC anymore because they know very well that the precooler would be completely iced up in no time. They can fake a short test on the ground but not in an actual flying and accelerating plane.

After changing their logo it's now time they also change their name. I suggest 'Radiator Exchangers' which better reflects REL's actual capabilities.

Yet more news from REL.

Reaction Engines is delighted to provide an update on the progress being made on the Cranfield Aerospace Solutions (CAeS) Project Fresson.

Project Fresson Update - Phase 1 Underway | Reaction Engines - Making Beyond Possible

Reaction Engines | Pioneering space access and sustainable technologies to elevate life on Earth.reactionengines.co.uk

.........................................

Reaction Engines announced that it joined the Project Fresson consortium led by CAeS in October 2021, with the aim to apply its revolutionary thermal management technology developed as part of the SABRE programme, to act as a key enabler for hydrogen fuel cell applications.

................................

Reaction Engines’ heat exchanger technology has been demonstrated as a key enabler for a lightweight and low drag solution. ...............................

Breaking News: REL has sold another radiator, assuming Project Fresson will actually go ahead. The REL financiers will be overjoyed.

Since Mark Thomas is CEO the REL propaganda has changed from laughable into absurdly bombastic. Everything they do is at least "advanced", but more often "innovative", "revolutionary", "ground-breaking", "world-leading", "phenominal".

Calling a rather simple tubular heat exchanger a "revolutionary thermal management technology" is already absurd but now they even call themselves a "key enabler", as if the whole project could not exist without them. What arrogance. For this project their radiator is no more a "key enabler" than the landing gear tyres or the pilot seat.

Last edited: