jmkorhonen

Diletantte

...so as not to hijack the British thread!

Let's start with a subject to which I hope to be able to make a meager contribution to: design constraints and philosophy behind design decisions.

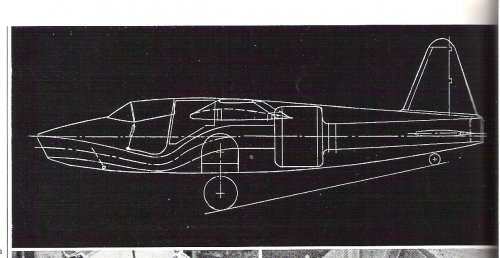

Hermione Giffard's PhD thesis and hopefully soon-to-be book "The Development and Production of Turbojet Aero-Engines in Britain, Germany and the United States, 1936-1945" (2011) argues that German and British gas turbine development was (at least in part) guided by quite different design philosophies and quality goals. Although the following is a crude generalization, the difference seems to be that the British were developing jet engines to standards expected of from piston aero engines (e.g. reliability, materials usage, MBTO etc.), while the Germans - specifically in the last half of the war - were doing "ersatz piston engines."

Giffard makes (IMHO) quite a convincing case that many of the German design decisions, with the possible exception of the adoption of axial flow scheme (which, however, was largely "locked in" by earlier design considerations), may be more fruitfully interpreted in the light of ease of production and conservation of raw materials. Turbojets fit nicely into the "armaments miracle" drive that sought to compensate the crushing manufacturing superiority of the Allies by rationalization, mass production, and focus on quantity even at the expense of quality. The man-hours required for a turbojet, for example, were a fraction of the man-hours required for a comparable piston engine, and raw material expenditure was far lower (more on that below). Lower quality was also acceptable because the expected lifetime of the engines was not a limiting factor - the expected lifetime of airframe into which the engines were mounted was, at this point in the war (1944) usually shorter than the expected lifetime of the engine.

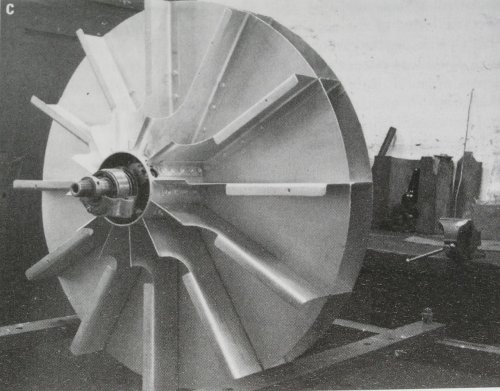

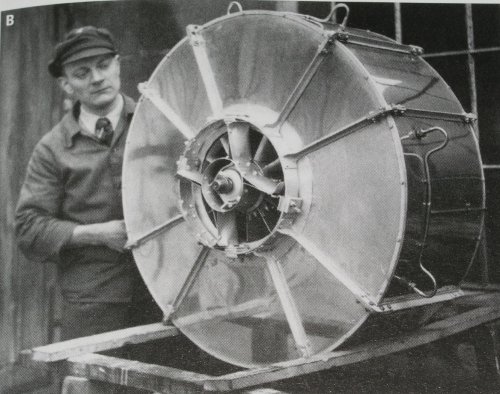

When seen in this light, several interesting design decisions become, in my opinion, more understandable. For example, one thing that had puzzled me was the frequent claim that nickel shortages had "caused" the development of the hollow turbine blades. Several scholars in the field of technology & innovation studies (e.g. Gibbert & Scranton 2009) have claimed that Ni shortage "induced" this "radical innovation" that put the German jet engine designers several years ahead of the Allies and caused them to "invent" a technology that is in use even now.

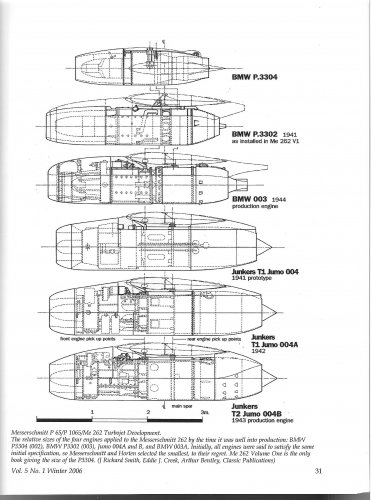

However, this version of the events seems a bit problematic when one considers the actual nickel usage and Germany's nickel situation. According to figures for Ni usage per engine in Kay's "German Jet Engine and Gas Turbine Development 1930-1945" (2002), the entire production run of Jumo 004 engines, for example (some 6010 engines) used approximately 40 metric tons of nickel. This is not an insignificant amount, but compared to 1944 Ni supplies (10900 tons), consumption (9500 tons), or stocks (7900 tons) (U.S. Strategic Bombing Survey), the needs amount to little more than rounding error.

Even if the wildly optimistic turbojet production plans, calling for ca. 39 000 BMW 003 and 44 000 Jumo 004 engines to be built by January 1946 had materialized, the nickel use would have been only some 250 tons. And even if the hollow blade designs - which, at best, saved some two thirds of nickel per engine compared to solid Tinidur blades - had not succeeded, the nickel consumption would have been only about 820 tons.

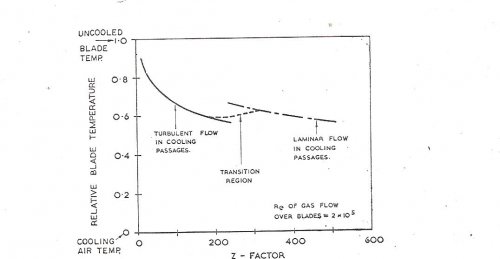

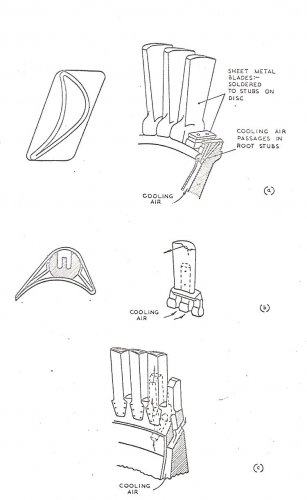

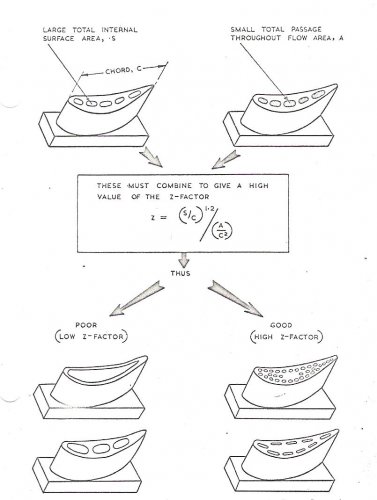

So, to me it seems that the relationship between nickel shortage and hollow blades is not as straightforward as it may seem. As Giffard argues, another (and perhaps the key) factor in favor of hollow blades was the ease of manufacture: hollow blades were deep drawn or folded and welded from sheet metal stock, and both operations were much more conductive to mass production using unskilled (slave) labor. Nickel savings were a plus.

I'm not claiming that the designers had all the nickel they wanted: there is no doubt that the designers "felt" the nickel shortage in the form of specifications and demands issued. For example, according to Kay (2002:107), in 1944, a specification for BMW 003 A-1 production series engine requested that engine had to be produced for about 500 man-hours per unit, and that it should use no more than about 0.6 kg Ni per engine. (The requests were not quite achieved, but it was reasonably close.) But, in my mind, the interesting question is this: how the specifications came to be?

Specifications don't crop up in a vacuum, of course. Before the official request for 0.6 kg of nickel per engine could be made, either a) someone must have had a pretty good idea about what's the minimum amount of Ni an operational engine would need, or b) someone needed to be delusional. Not to say that the b) couldn't be a factor, but the evidence (the target was almost reached) points that the specification set a pretty reasonable if ambitious goal. The most likely explanation for that is there was at least some confidence that engines could be built with little Ni. And that confidence largely came from a history of experimentation with air-cooled turbine blades.

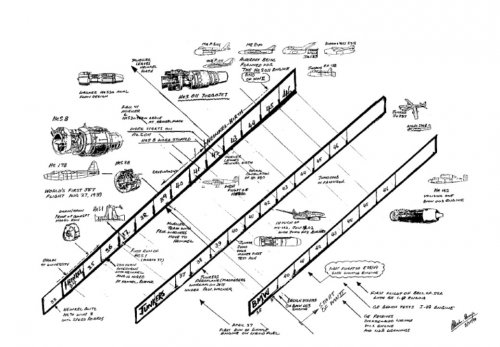

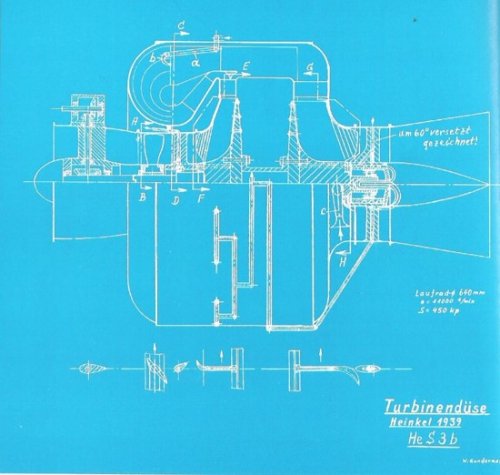

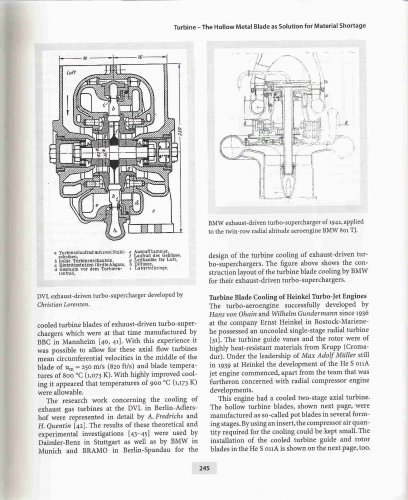

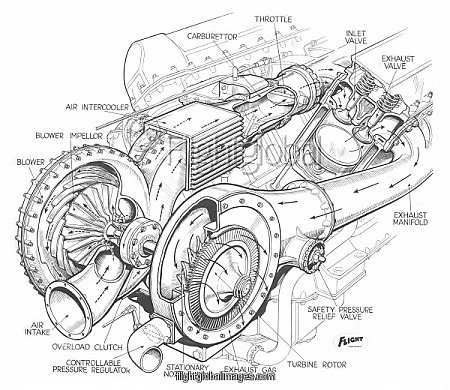

The German industry had been aware that in any possible war, nickel would be one of the key metals in short supply. Consequently, even before the war, efforts had been made to develop alternatives and R&D on nickel-heavy alloys was curtailed: e.g. Krupp works did not introduce an improved Tinidur alloy with 60% instead of 30% Ni because of the anticipated shortage, even though the high temperature advantages were known (Meher-Homji 1997). One of the areas in which this awareness manifested itself was in superchargers, which were the first applications of hollow turbine blades: a BMW turbo-supercharger ran successfully at 900°C in 1938, using internally air-cooled blades.

I argue that it was this and other successful hollow-blade developments that influenced the perceived nickel shortage by at least as much as the actual supply situation. Because the powers that be knew that turbines without solid nickel-alloy blades could be manufactured, and that they were easier to manufacture than milled turbine blades, the specifications could confidently call for very low Ni content per engine, and the armaments ministry could get by lower Ni allocations to jet engine manufacturers. True, the anticipated nickel shortage was one reason the engineers started to design workarounds in the first place, but if these efforts had failed, I don't see any reason why the Germans would have been unable to continue using solid blades (as used in Jumo 004 B-1, which was the only turbojet to power planes that actually reached combat) or even introduce alloys similar to Nimonic 80 for the jet engine program - although that would probably have been excessive, given the likely lifetime of the airframes. After all, even with Nimonic, the nickel use per jet engine would have been less than what was needed for comparable piston engines! (My approximation based on early 1942 data on aero-engine industry nickel consumption is, on average, 50 kg per piston engine. I'm not certain what that includes - it may include tools and dies and all the other stuff required in the supply chain. Any info would be much appreciated.)

A bit longer version of this case study may (hopefully) become a part of my PhD thesis. My thesis draws from the history of technology and, at this point, seems to argue that the role of constraints in design and engineering might be understood a bit incompletely in the current science & technology studies literature: instead and in addition of "necessity being the mother of invention," technical possibility is one of the most influential parents of necessity, as defined by specifications and requirements. Any criticism would be much appreciated, much easier to change thinking at this stage when nothing's in print yet .

.

References:

Anonymous. 1938. Aeronautical Research: Dr. Seewald Describes the Work of the DVL. The Aircraft Engineer (Supplement to Flight), 16(11): 71–74.

Gibbert, M., & Scranton, P. 2009. Constraints as sources of radical innovation? Insights from jet propulsion development. Management & Organizational History, 4(4): 1–15.

Giffard, H. S. 2011. The Development and Production of Turbojet Aero-Engines in Britain, Germany and the United States, 1936-1945. Imperial College, University of London.

Kay, A. L. 2002. German Jet Engine and Gas Turbine Development 1930-1945. Ramsbury: The Crowood Press.

Meher-Homji, C. B. 1997. The Development of the Junkers Jumo 004B—The World’s First Production Turbojet. Journal of Engineering for Gas Turbines and Power, 119(4): 783. http://gasturbinespower.asmedigitalcollection.asme.org/article.aspx?articleid=1420400, March 30, 2013.

PS. an astute reader may note that I left out discussion of chromium from the above. I do not consider this to have been a critical resource for jet engine development, as (partial) switch to Cromadur blade material even increased Cr use per engine in order to conserve nickel.

Let's start with a subject to which I hope to be able to make a meager contribution to: design constraints and philosophy behind design decisions.

Hermione Giffard's PhD thesis and hopefully soon-to-be book "The Development and Production of Turbojet Aero-Engines in Britain, Germany and the United States, 1936-1945" (2011) argues that German and British gas turbine development was (at least in part) guided by quite different design philosophies and quality goals. Although the following is a crude generalization, the difference seems to be that the British were developing jet engines to standards expected of from piston aero engines (e.g. reliability, materials usage, MBTO etc.), while the Germans - specifically in the last half of the war - were doing "ersatz piston engines."

Giffard makes (IMHO) quite a convincing case that many of the German design decisions, with the possible exception of the adoption of axial flow scheme (which, however, was largely "locked in" by earlier design considerations), may be more fruitfully interpreted in the light of ease of production and conservation of raw materials. Turbojets fit nicely into the "armaments miracle" drive that sought to compensate the crushing manufacturing superiority of the Allies by rationalization, mass production, and focus on quantity even at the expense of quality. The man-hours required for a turbojet, for example, were a fraction of the man-hours required for a comparable piston engine, and raw material expenditure was far lower (more on that below). Lower quality was also acceptable because the expected lifetime of the engines was not a limiting factor - the expected lifetime of airframe into which the engines were mounted was, at this point in the war (1944) usually shorter than the expected lifetime of the engine.

When seen in this light, several interesting design decisions become, in my opinion, more understandable. For example, one thing that had puzzled me was the frequent claim that nickel shortages had "caused" the development of the hollow turbine blades. Several scholars in the field of technology & innovation studies (e.g. Gibbert & Scranton 2009) have claimed that Ni shortage "induced" this "radical innovation" that put the German jet engine designers several years ahead of the Allies and caused them to "invent" a technology that is in use even now.

However, this version of the events seems a bit problematic when one considers the actual nickel usage and Germany's nickel situation. According to figures for Ni usage per engine in Kay's "German Jet Engine and Gas Turbine Development 1930-1945" (2002), the entire production run of Jumo 004 engines, for example (some 6010 engines) used approximately 40 metric tons of nickel. This is not an insignificant amount, but compared to 1944 Ni supplies (10900 tons), consumption (9500 tons), or stocks (7900 tons) (U.S. Strategic Bombing Survey), the needs amount to little more than rounding error.

Even if the wildly optimistic turbojet production plans, calling for ca. 39 000 BMW 003 and 44 000 Jumo 004 engines to be built by January 1946 had materialized, the nickel use would have been only some 250 tons. And even if the hollow blade designs - which, at best, saved some two thirds of nickel per engine compared to solid Tinidur blades - had not succeeded, the nickel consumption would have been only about 820 tons.

So, to me it seems that the relationship between nickel shortage and hollow blades is not as straightforward as it may seem. As Giffard argues, another (and perhaps the key) factor in favor of hollow blades was the ease of manufacture: hollow blades were deep drawn or folded and welded from sheet metal stock, and both operations were much more conductive to mass production using unskilled (slave) labor. Nickel savings were a plus.

I'm not claiming that the designers had all the nickel they wanted: there is no doubt that the designers "felt" the nickel shortage in the form of specifications and demands issued. For example, according to Kay (2002:107), in 1944, a specification for BMW 003 A-1 production series engine requested that engine had to be produced for about 500 man-hours per unit, and that it should use no more than about 0.6 kg Ni per engine. (The requests were not quite achieved, but it was reasonably close.) But, in my mind, the interesting question is this: how the specifications came to be?

Specifications don't crop up in a vacuum, of course. Before the official request for 0.6 kg of nickel per engine could be made, either a) someone must have had a pretty good idea about what's the minimum amount of Ni an operational engine would need, or b) someone needed to be delusional. Not to say that the b) couldn't be a factor, but the evidence (the target was almost reached) points that the specification set a pretty reasonable if ambitious goal. The most likely explanation for that is there was at least some confidence that engines could be built with little Ni. And that confidence largely came from a history of experimentation with air-cooled turbine blades.

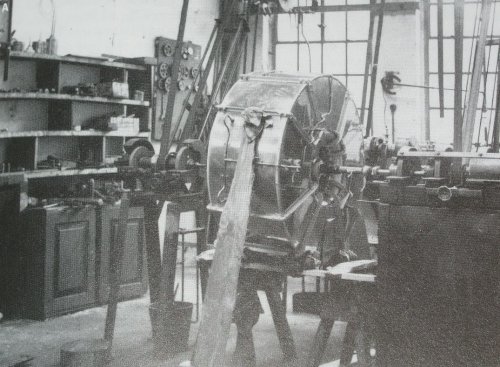

The German industry had been aware that in any possible war, nickel would be one of the key metals in short supply. Consequently, even before the war, efforts had been made to develop alternatives and R&D on nickel-heavy alloys was curtailed: e.g. Krupp works did not introduce an improved Tinidur alloy with 60% instead of 30% Ni because of the anticipated shortage, even though the high temperature advantages were known (Meher-Homji 1997). One of the areas in which this awareness manifested itself was in superchargers, which were the first applications of hollow turbine blades: a BMW turbo-supercharger ran successfully at 900°C in 1938, using internally air-cooled blades.

I argue that it was this and other successful hollow-blade developments that influenced the perceived nickel shortage by at least as much as the actual supply situation. Because the powers that be knew that turbines without solid nickel-alloy blades could be manufactured, and that they were easier to manufacture than milled turbine blades, the specifications could confidently call for very low Ni content per engine, and the armaments ministry could get by lower Ni allocations to jet engine manufacturers. True, the anticipated nickel shortage was one reason the engineers started to design workarounds in the first place, but if these efforts had failed, I don't see any reason why the Germans would have been unable to continue using solid blades (as used in Jumo 004 B-1, which was the only turbojet to power planes that actually reached combat) or even introduce alloys similar to Nimonic 80 for the jet engine program - although that would probably have been excessive, given the likely lifetime of the airframes. After all, even with Nimonic, the nickel use per jet engine would have been less than what was needed for comparable piston engines! (My approximation based on early 1942 data on aero-engine industry nickel consumption is, on average, 50 kg per piston engine. I'm not certain what that includes - it may include tools and dies and all the other stuff required in the supply chain. Any info would be much appreciated.)

A bit longer version of this case study may (hopefully) become a part of my PhD thesis. My thesis draws from the history of technology and, at this point, seems to argue that the role of constraints in design and engineering might be understood a bit incompletely in the current science & technology studies literature: instead and in addition of "necessity being the mother of invention," technical possibility is one of the most influential parents of necessity, as defined by specifications and requirements. Any criticism would be much appreciated, much easier to change thinking at this stage when nothing's in print yet

References:

Anonymous. 1938. Aeronautical Research: Dr. Seewald Describes the Work of the DVL. The Aircraft Engineer (Supplement to Flight), 16(11): 71–74.

Gibbert, M., & Scranton, P. 2009. Constraints as sources of radical innovation? Insights from jet propulsion development. Management & Organizational History, 4(4): 1–15.

Giffard, H. S. 2011. The Development and Production of Turbojet Aero-Engines in Britain, Germany and the United States, 1936-1945. Imperial College, University of London.

Kay, A. L. 2002. German Jet Engine and Gas Turbine Development 1930-1945. Ramsbury: The Crowood Press.

Meher-Homji, C. B. 1997. The Development of the Junkers Jumo 004B—The World’s First Production Turbojet. Journal of Engineering for Gas Turbines and Power, 119(4): 783. http://gasturbinespower.asmedigitalcollection.asme.org/article.aspx?articleid=1420400, March 30, 2013.

PS. an astute reader may note that I left out discussion of chromium from the above. I do not consider this to have been a critical resource for jet engine development, as (partial) switch to Cromadur blade material even increased Cr use per engine in order to conserve nickel.