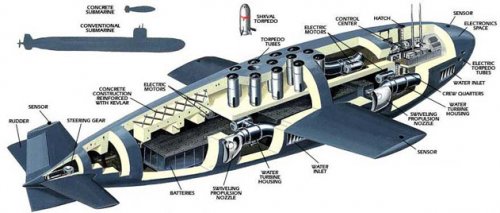

I am sure that many remember this Popular Mechanics article or one of the many like it back then on a rumoured type of Russian concrete sub with 200 mph Shkval rocket torpedoes:

Concrete Submarines

Cheap and deadly, these stealthy boats could shift the balance of naval power.

December 1998

Popular Mechanics

The thing is, aside from the hype, both the concrete construction and the heavier-than-water submarine concept do seem to have merit. Does anyone know of actual craft or serious proposals for concrete and/or neutral-to-negative buoyancy submarines?

Concrete Submarines

Cheap and deadly, these stealthy boats could shift the balance of naval power.

December 1998

Popular Mechanics

The thing is, aside from the hype, both the concrete construction and the heavier-than-water submarine concept do seem to have merit. Does anyone know of actual craft or serious proposals for concrete and/or neutral-to-negative buoyancy submarines?