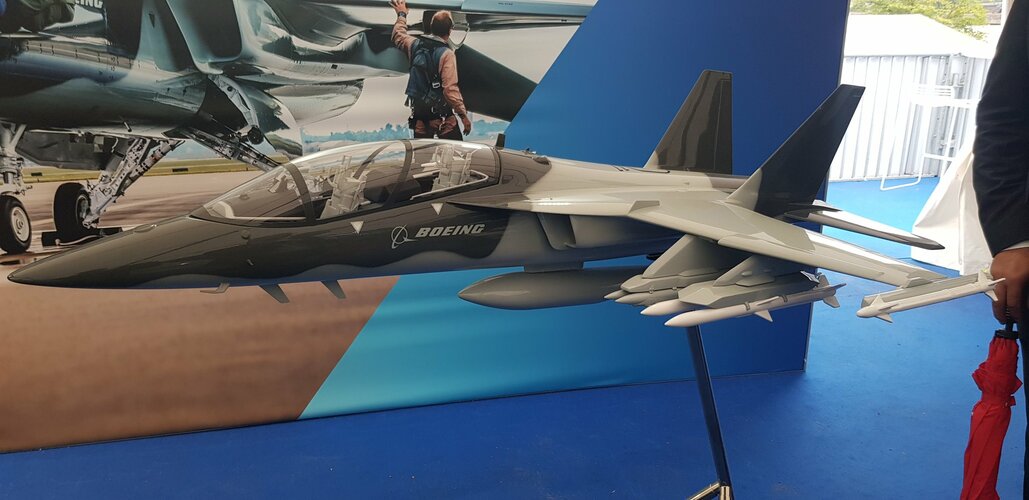

I think it's really interesting that Boeing opted to "revert" back to producing an all aluminium aircraft and possibly heralds a new era for metal aircraft. Despite any weight and flexibility advantages composites would've given them, aluminium can be, formed, welded, and even installed with fewer human hours on it....... The composite craze really only seems necessary for military aircraft riding a bleeding edge in performance and capability (in particular for stealth), or particular edge cases (corrosion resistance for naval aircraft). Otherwise, the production savings of metal seem to well out-weight the amount of man-hours composites really require, conforms very well to new digital manufacturing systems, and offers easier maintainability.

Composites could win in the economy of scale in civil aircraft with potential production runs into the thousands, but a few hundred airframes will be more cost and time sensitive, making all metal construction very applicable in the T-7A's case. Replacing metal panels with composites would be a worthwhile upgrade if a larger production run becomes established.

That's my guess, and I think more analysis on aircraft manufacturing processes would be a welcome topic on this site.