What is known about this machine gun?

" Italian inventors, like those of every other nation in Europe, felt as a matter of national pride that their military forces should be armed with an automatic machine gun that was not only designed but fabricated in their own country.

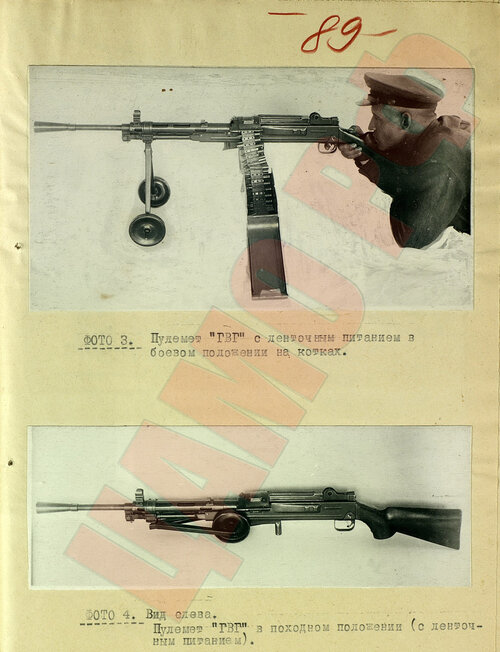

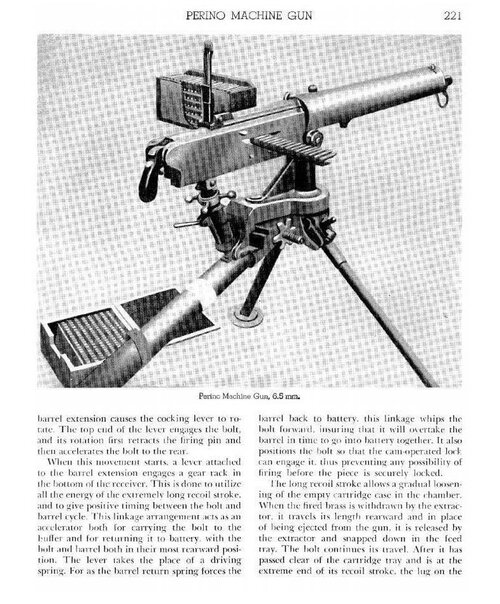

In 1901 Giuseppe Perino, officer in charge of the Italian artillery factory in Rome, designed a machine gun that must still be admired today for its many advanced features.

The Italian Government, coming to the conclusion that it had a superior arm, immediately placed it in confidential status. Only a few at a time were built and experimented with, until it was felt the weapon was improved enough to compete with well-known machine guns.

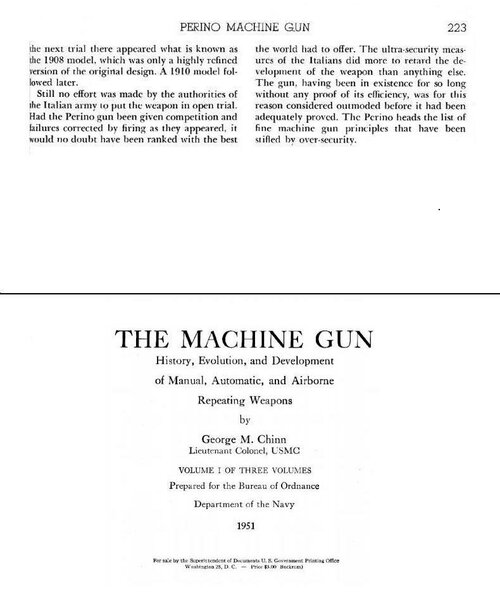

In 1908 the government conducted a secret trial to compare the Perino with the Maxim. The test revealed that the Perino had a higher rate of fire than the latter, and that when water boiled in the jacket from prolonged bursts, the liquid could be changed during continued operation in the Italian gun but not in the other.

The mechanism was also found to be of simpler construction and was far easier to handle in the field, although it weighed 50 pounds without mount.

The most objectionable feature noted by the examining board was the delay caused by the need for manual removal of empty cartridge cases from the strips before they could be reloaded. This was an odd complaint since it was a by-product of one of the best and most unique methods of feeding to be found at this early date.

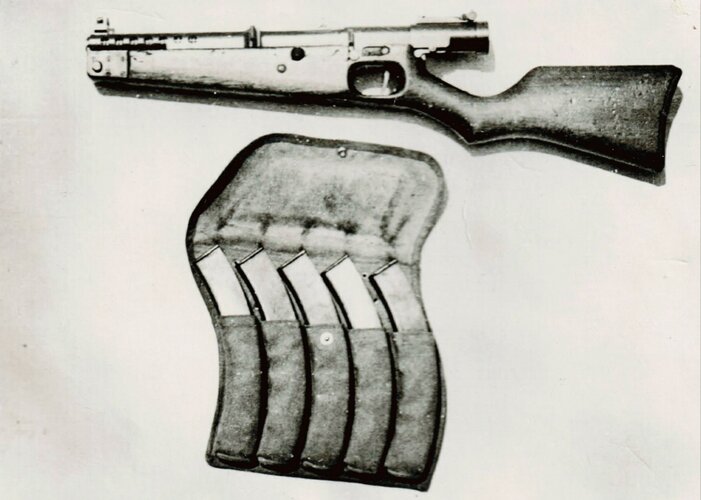

Metal trays holding 25 rounds of 6.5-mm cartridges were fed into the gun from left to right. The ammunition box held five such trays or clips. The weapon fed the trays one at a time from the bottom of the ammunition container. In this manner it was easy for the gunner's assistant to keep the box full by laying loaded ones on top of the stack. It also allowed a sustained fire as long as the gun functioned. A loaded tray followed immediately behind the ejection of an expended one from the right side of the weapon with the empty brass reclipped in the tray. In this manner of feeding, no metal link or fabric belt was required and no case ejection chute was necessary, since the empty case was placed back in the tray after being extracted from the chamber.

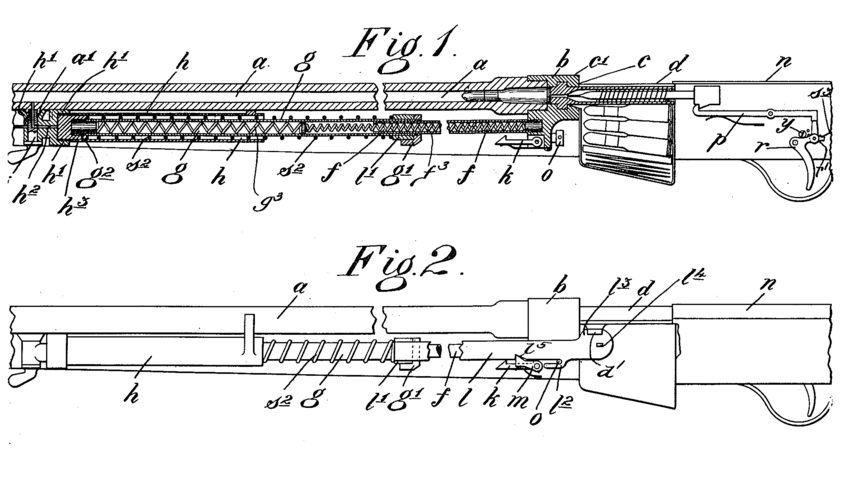

To fire the Perino, a clip or tray of ammunition is inserted in the feed opening on the left side. This is done only when the bolt is in battery, and secured by the pivot lock that is fastened to the barrel extension and engages the locking grooves on both top and bottom of the bolt.

The charging handle is then pulled smartly to the rear. When it reaches its full rearward stroke, a sear engages the bolt recess and holds it in the cocked-bolt position. This movement also indexes a round in position to be chambered. Upon pulling the trigger, the sear releases the bolt, which is then driven forward by the stored energy of the barrel-return spring. The bolt does not strip the round, as in most other machine guns of this type, but pushes it out of the clip into the chamber. It actually passes over the top of the clip where the cartridge was formerly held.

When the round is chambered, it is fired by inertia after the bolt is securely locked. After firing, the barrel, barrel extension, and bolt are locked together until the barrel pressure has reached a safe operating limit. At this point the unlocking lug of the lock engages a cam in a fixed receiver and pivots the lock to free the bolt from the barrel.

At the instant the bolt is freed, the cocking device, consisting of a two-forked lever pinned to the barrel extension, strikes a fixed stop in the bottom of the receiver. Further recoil of the

barrel extension causes the cocking lever to rotate. The top end of the lever engages the bolt, and its rotation first retracts the firing pin and then accelerates the bolt to the rear.

When this movement starts, a lever attached to the barrel extension engages a gear rack in the bottom of the receiver. This is done to utilize all the energy of the extremely long recoil stroke, and to give positive timing between the bolt and barrel cycle. This linkage arrangement acts as an accelerator both for carrying the bolt to the buffer and for returning it to battery, with the bolt and barrel both in their most rearward position. The lever takes the place of a driving spring. For as the barrel return spring forces the barrel back to battery, this linkage whips the bolt forward, insuring that it will overtake the barrel in time to go into battery together. It also positions the bolt so that the cam-operated lock can engage it, thus preventing any possibility of firing before the piece is securely locked.

The long recoil stroke allows a gradual loosening of the empty cartridge case in the chamber. When the fired brass is withdrawn by the extractor, it travels its length rearward and in place of being ejected from the gun, it is released by the extractor and snapped down in the feed tray. The bolt continues its travel. After it has passed clear of the cartridge tray and is at the extreme end of its recoil stroke, the lug on the

barrel extension cams the feed tray over one space, indexing the next round into position. If the trigger is held, the automatic action will continue.

Italy planned to manufacture the Perino weapon in its federal arms plants, believing that this, coupled with its simple design, would allow the economical production of one of the world's finest machine guns.

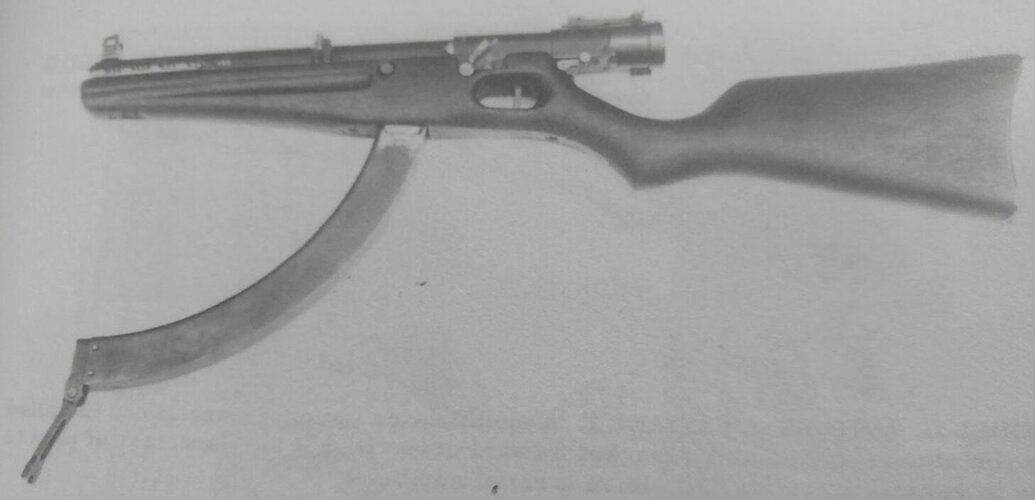

After the secret trials the only important change was an alternate method of supplying cartridges besides the strip feed. This modification consisted of a drum arrangement on the left side of the weapon upon which was rolled the belted ammunition fixed on a flexible brass strip. The feature of rebelting empty cartridge cases was retained. The loaded ammunition still was fed in from the left side while the belted empty brass emerged from the right. The belts had a quick detachable snap at two-foot intervals, so that the gunner could instantly separate the strip if he cared to move the weapon's position when the empty brass and belt began to pile up.

This model was designed for cooling both by air and water. When the latter method was used, the barrel acted as a small reciprocating pump operating from recoil, insuring a constant circulation of water in the jacket during firing. A longitudinally ribbed barrel was employed, aiding in the control of dispersion when long bursts were fired. The ribs gave added strength with little weight and allowed considerably more surface for radiation.

A built-in device at the muzzle, after permitting the bullet to clear the bore safely, trapped the blast. This heretofore wasted energy was employed to accelerate the recoil further. No driving spring was used in this weapon, as the barrel-return spring and accelerator lever returned the bolt to battery. A muzzle booster with this unusual bolt action reached its highest efficiency at 600 shots per minute.

The cartridge was indexed by the surplus barrel-recoil energy. The ammunition tray or belt, if the latter was used, could be released from the mechanism of the weapon merely by pushing a button disconnect. This permitted the clearing of a feed failure without access to the working parts.

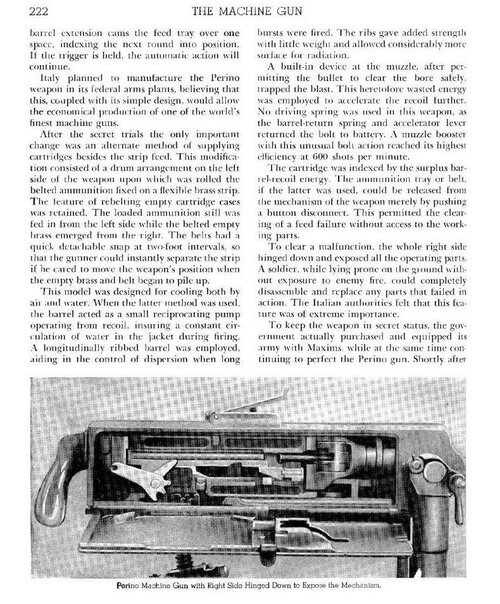

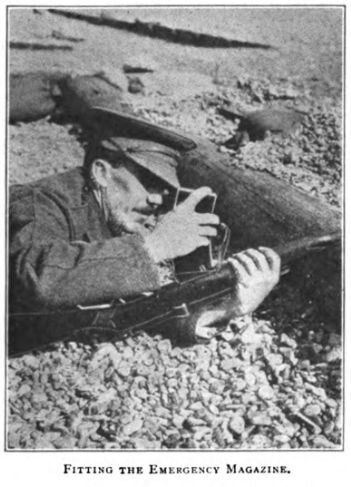

To clear a malfunction, the whole right side hinged down and exposed all the operating parts. A soldier, while lying prone on the ground without exposure to enemy fire, could completely disassemble and replace any parts that failed in action. The Italian authorities felt that this feature was of extreme importance.

To keep the weapon in secret status, the government actually purchased and equipped its army with Maxims, while at the same time continuing to perfect the Perino gun. Shortly after

the next trial there appeared what is known as the 1908 model, which was only a highly refined version of the original design. A 1910 model followed later.

Still no effort was made by the authorities of the Italian army to put the weapon in open trial. Had the Perino gun been given competition and failures corrected by firing as they appeared, it would no doubt have been ranked with the best the world had to offer. The ultra-security measures of the Italians did more to retard the development of the weapon than anything else. The gun, having been in existence for so long without any proof of its efficiency, was for this reason considered outmoded before it had been adequately proved. The Perino heads the list of fine machine gun principles that have been stifled by over-security."

https://www.ibiblio.org/hyperwar/USN/ref/MG/I/MG-3.html#perino

topwar.ru

Lobaev is developing 4 different new cartridges.

topwar.ru

Lobaev is developing 4 different new cartridges.

topwar.ru

Lobaev says that a new propellant will be used instead of gunpowder. In principle, this is quite reasonable, given that back in the 1940s, the Russians, during experiments with a 14.5 mm cartridge, using a liquid propellant, were able to achieve 2000 mps.

topwar.ru

Lobaev says that a new propellant will be used instead of gunpowder. In principle, this is quite reasonable, given that back in the 1940s, the Russians, during experiments with a 14.5 mm cartridge, using a liquid propellant, were able to achieve 2000 mps.