Sherman didn't benefit as much from the V12 as the M26 did because its suspension wouldn't be able to use the extra power to weight-ratio quite as well. At the same time, the VVSS Sherman wasn't deemed capable to take much extra weight (before M4A3E2) so the extra power couldn't really be used to maintain mobility at higher weights either. That said, a M4A4 was tested with the 650 Chrysler A65 which was very useful, so a better Packard V12 or Ford V12 may still have been a practical option. The Ford V8 also had a 60° bank angle which is not great for balance with that cylinder layout, the V12 didn't have that issue. With the M4A3E2 and the HVSS suspension Shermans which were substantially heavier, such an engine might have been useful as well. The V12s did require the extended hull of the M4A4 however.

In fact, the M4A4 itself could have certainly benefitted from one of the V12s if sufficient excess production could be obtained. You save an enormous amount of weight and space while increasing power, maintenance becomes easier and you can in turn use that freed space for fuel, easier access or accessories.

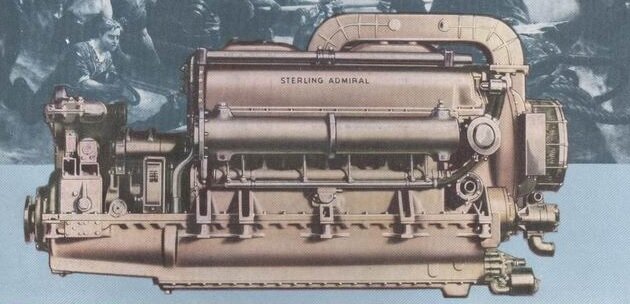

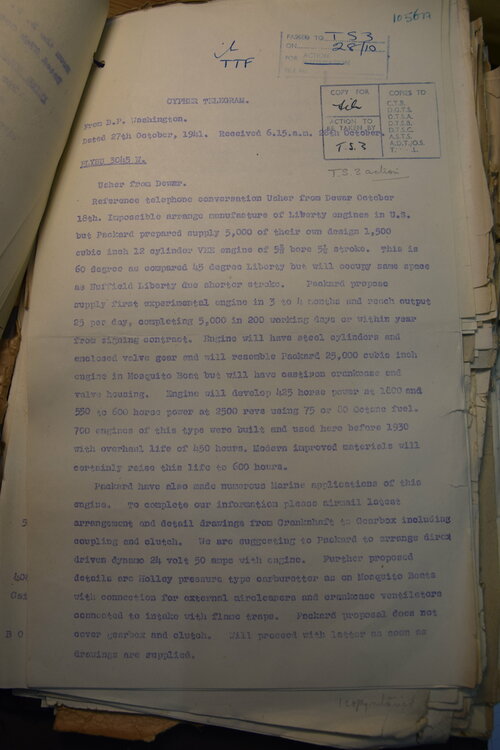

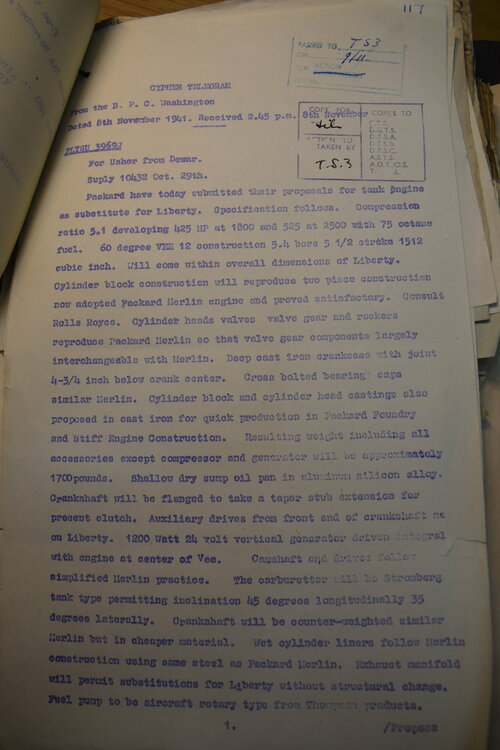

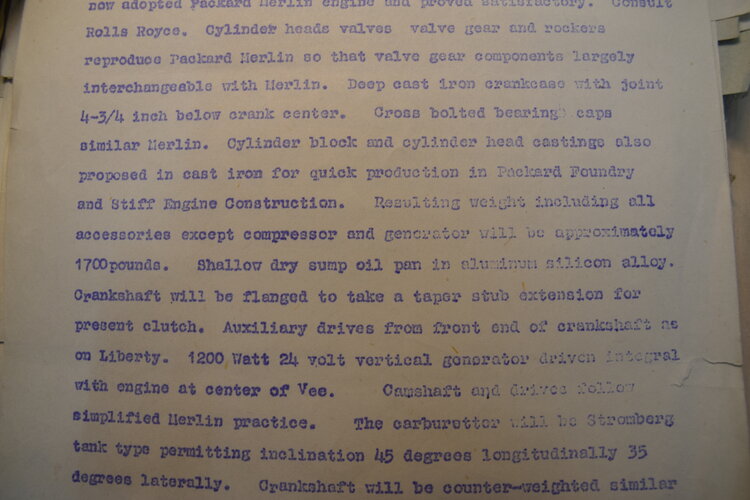

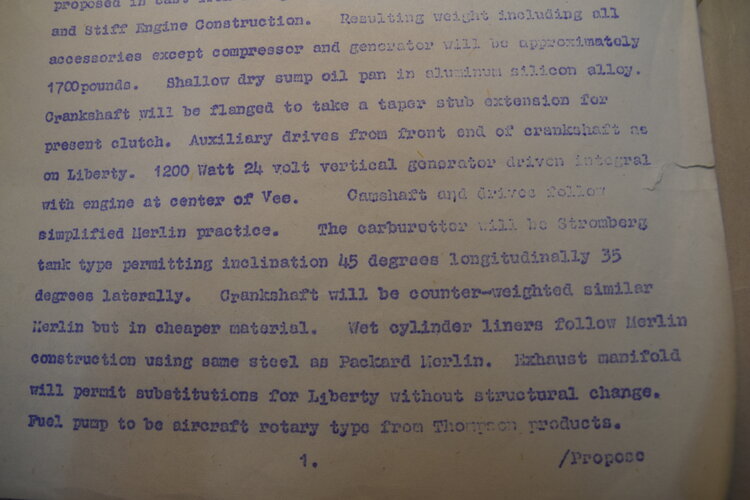

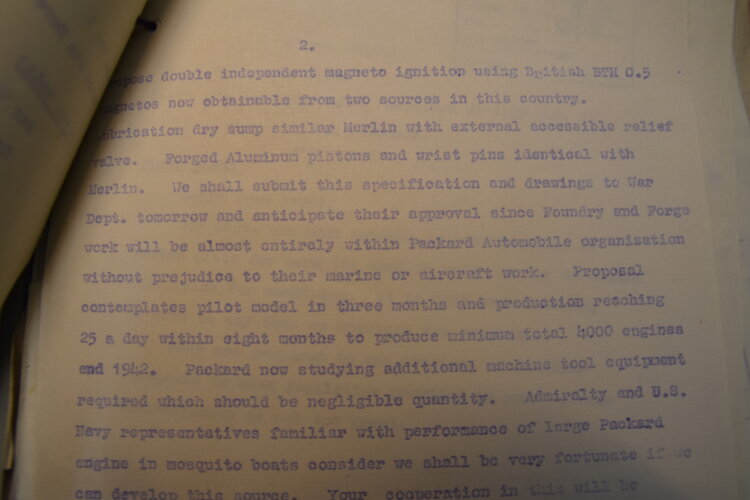

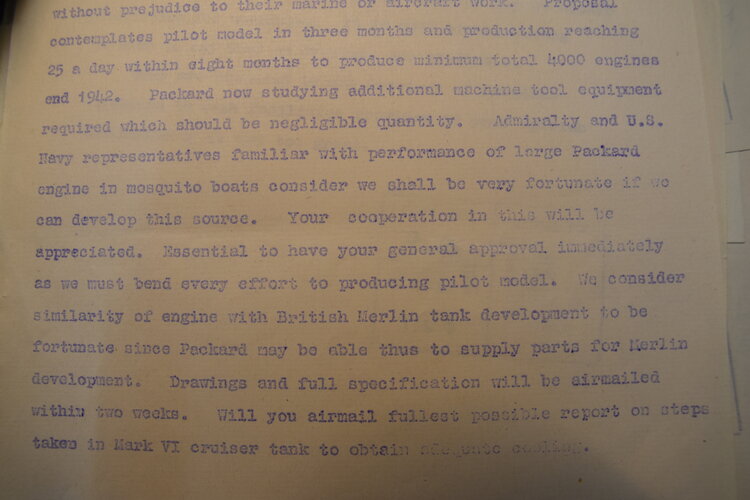

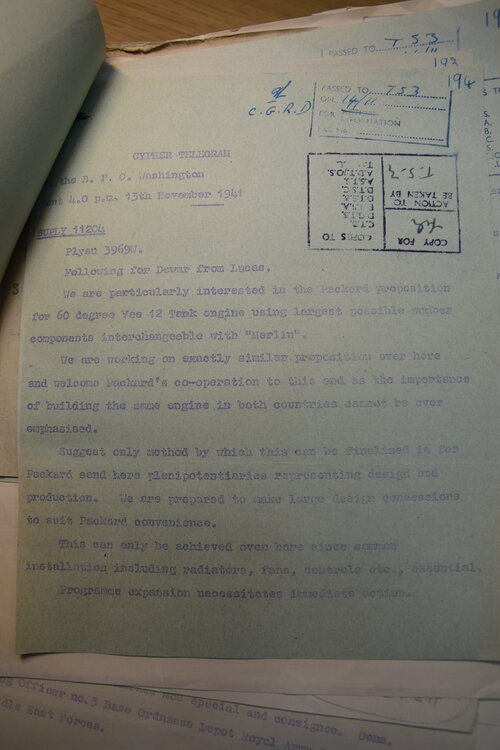

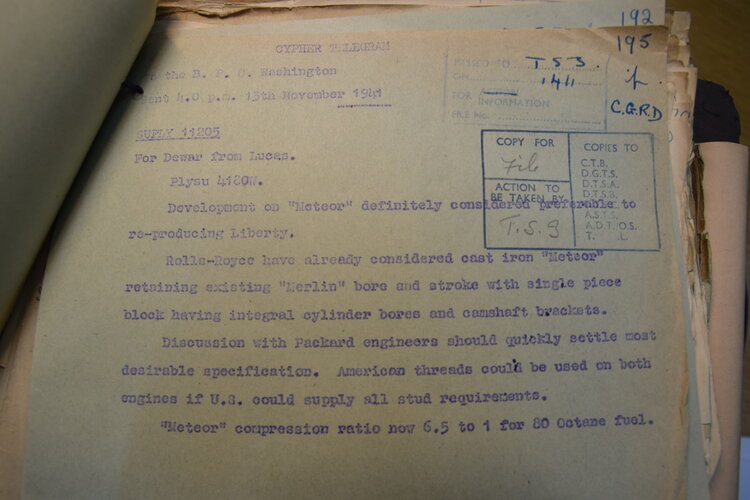

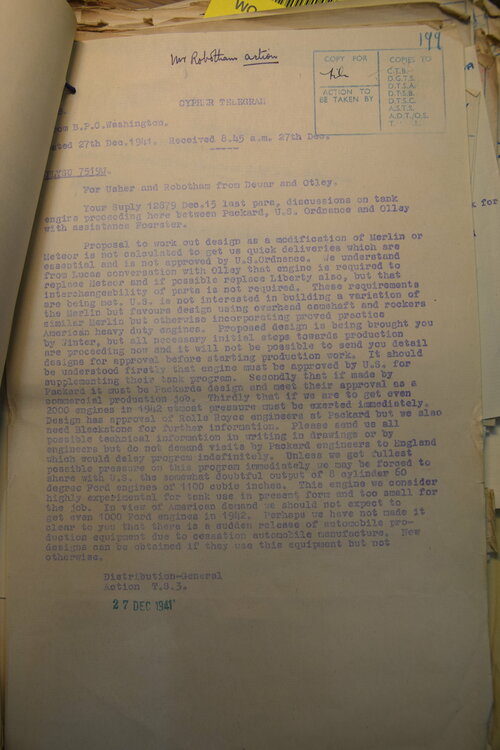

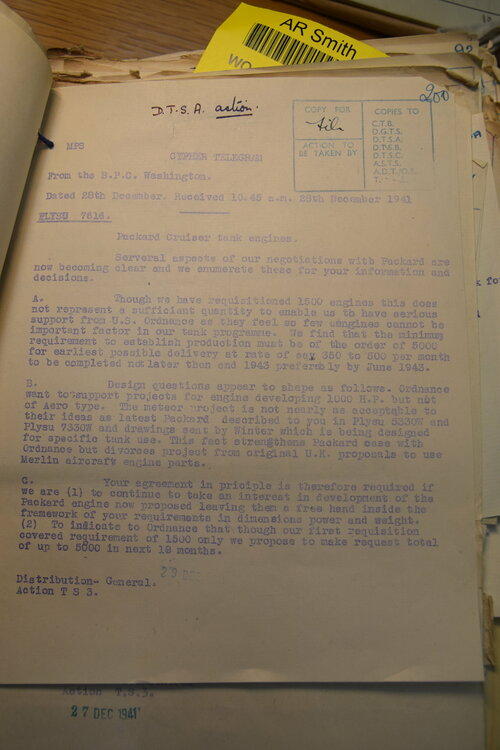

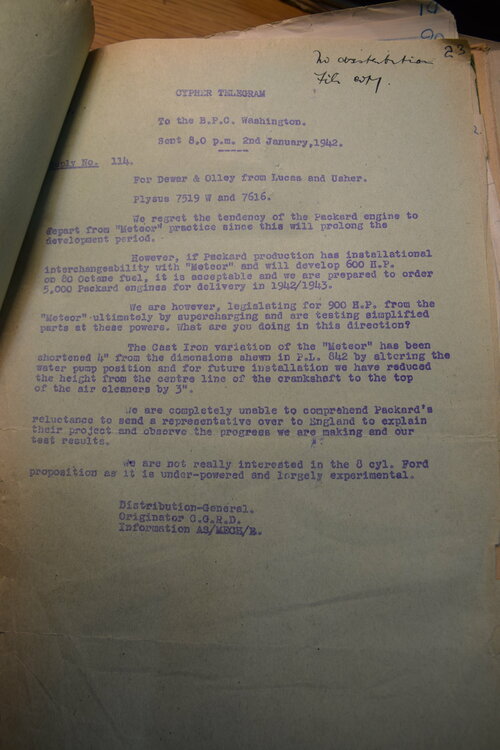

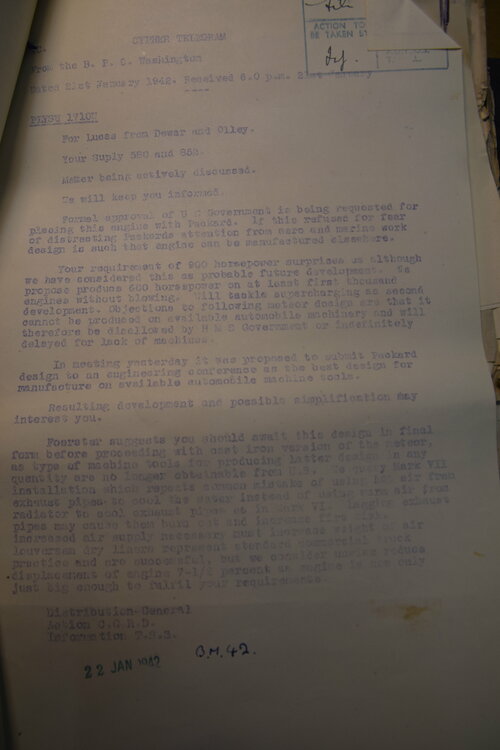

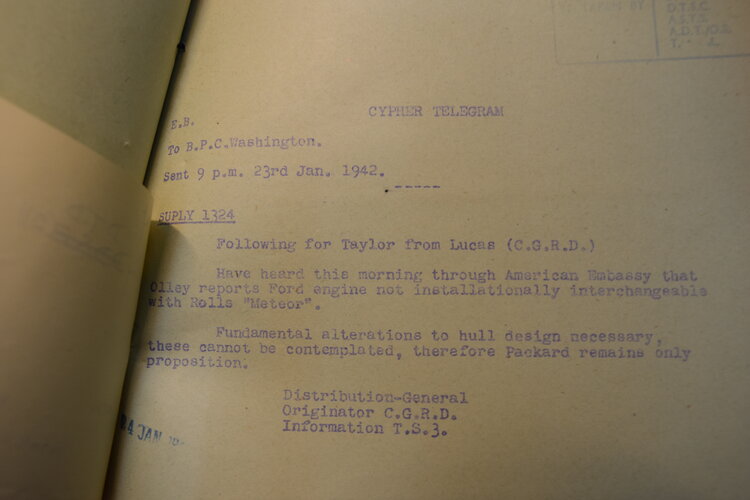

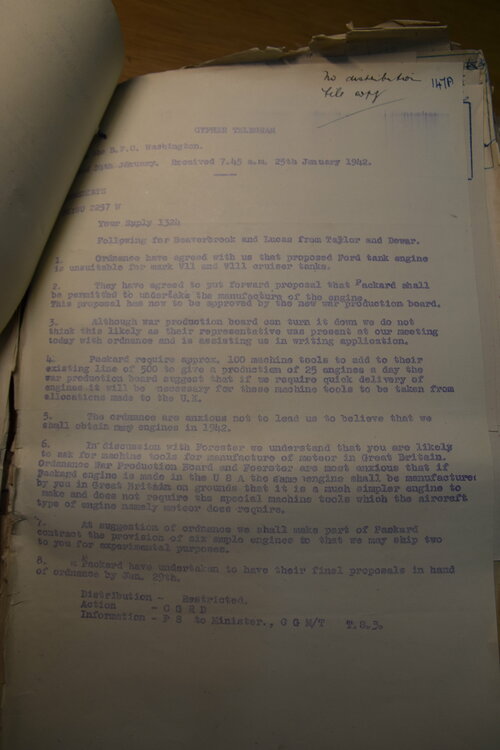

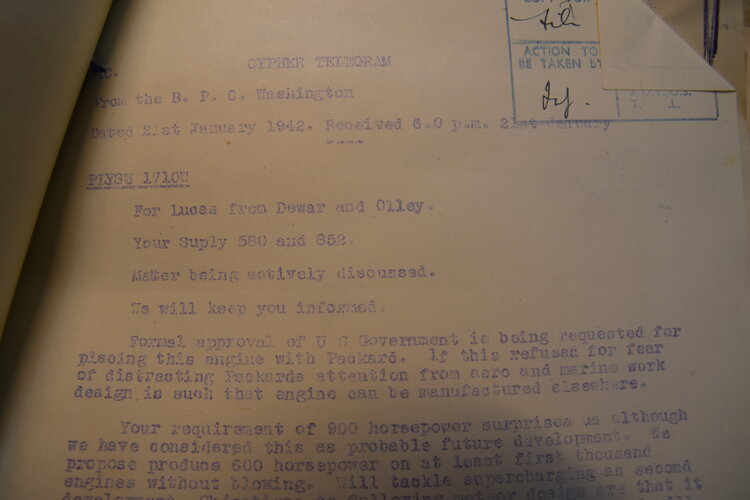

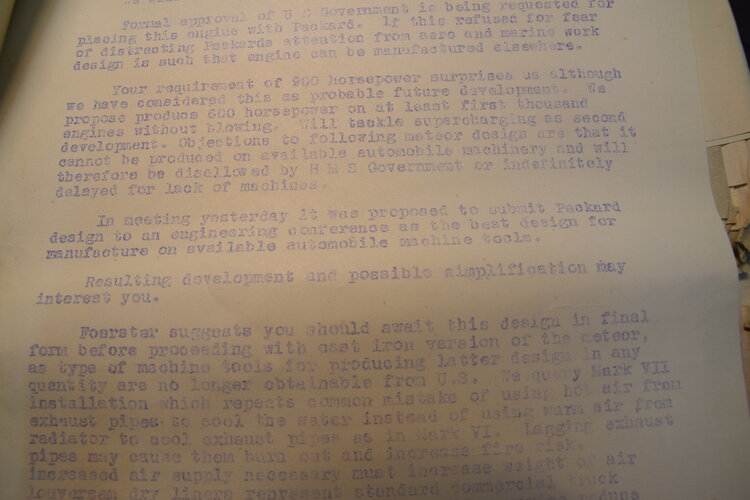

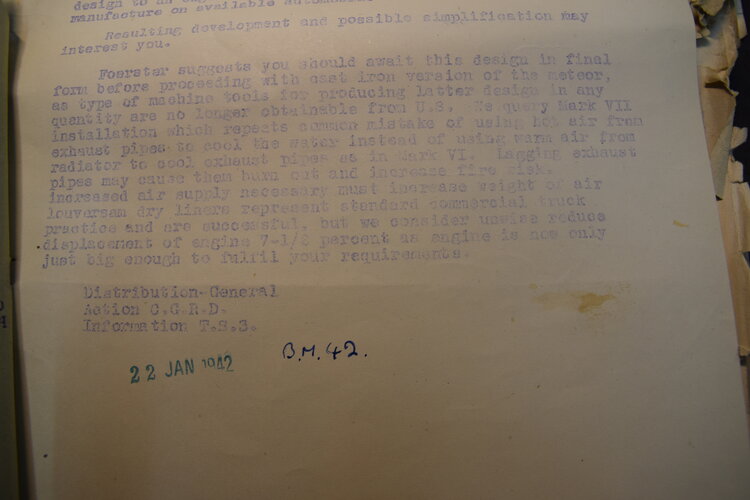

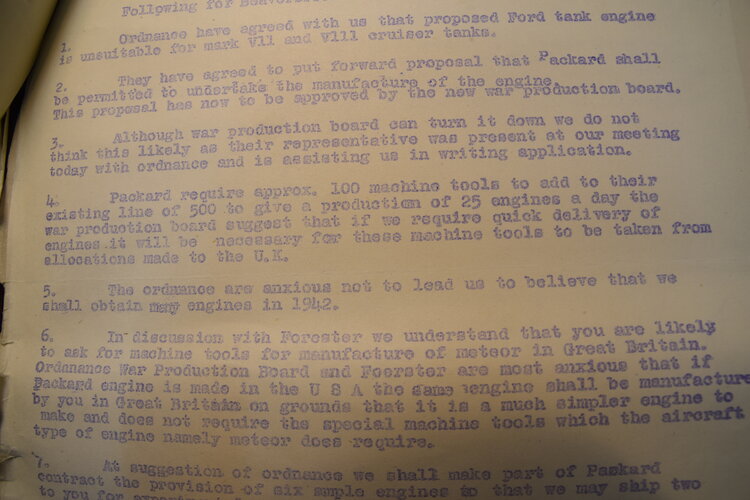

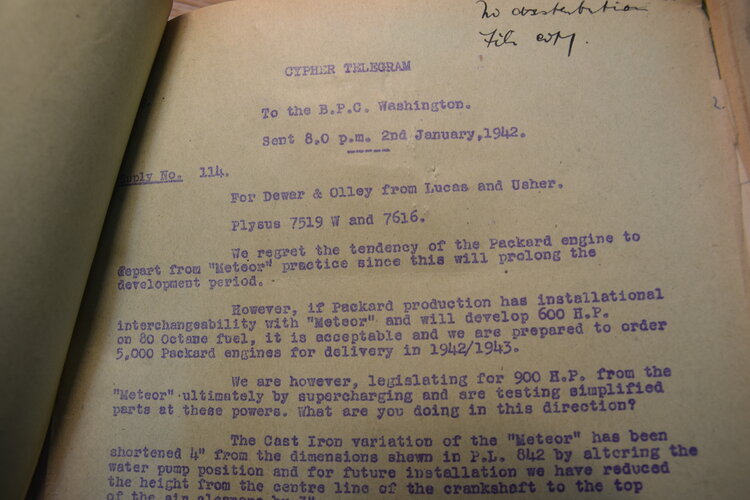

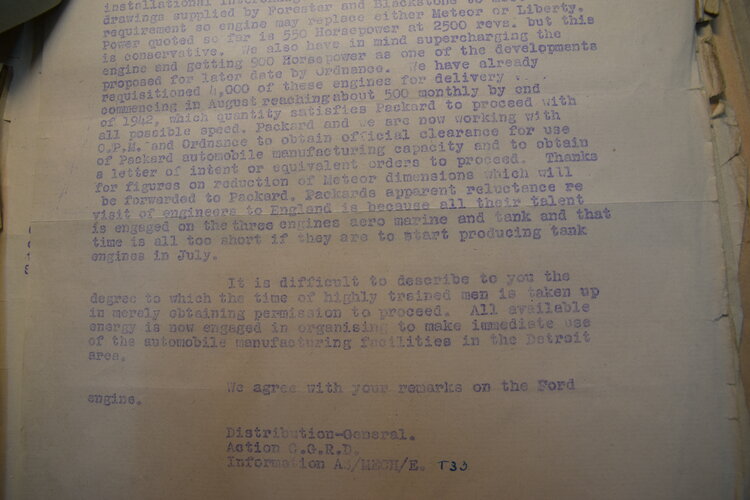

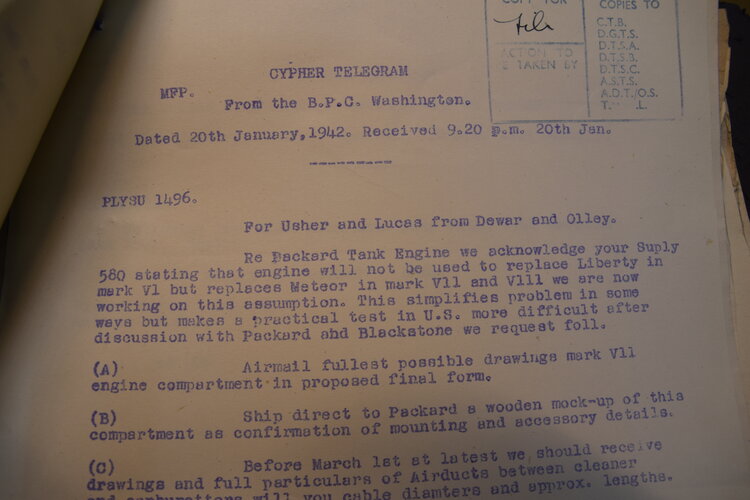

Packard V12 is overall worse than the Ford (heavier and less powerful), but thanks to the use of iron instead of aluminium parts, it is much cheaper and easier to manufacture with that automobile equipment. Expanding production of the Ford (V8) proved extremely difficult so it didn't manage to become the standard engine as desired. Had the US-UK gone through with the Packard as the eventually standard tank engine in 1942, it may have been a more practical proposition in spite of its more limited power potential.

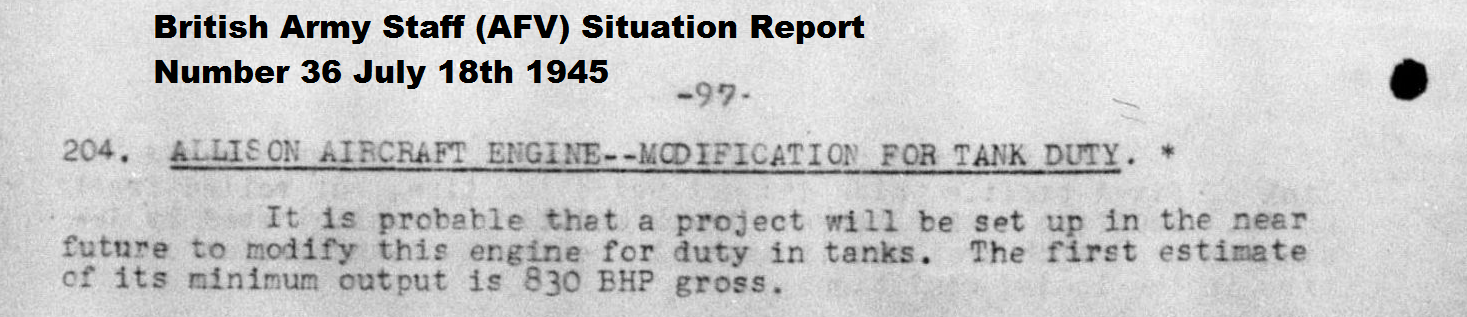

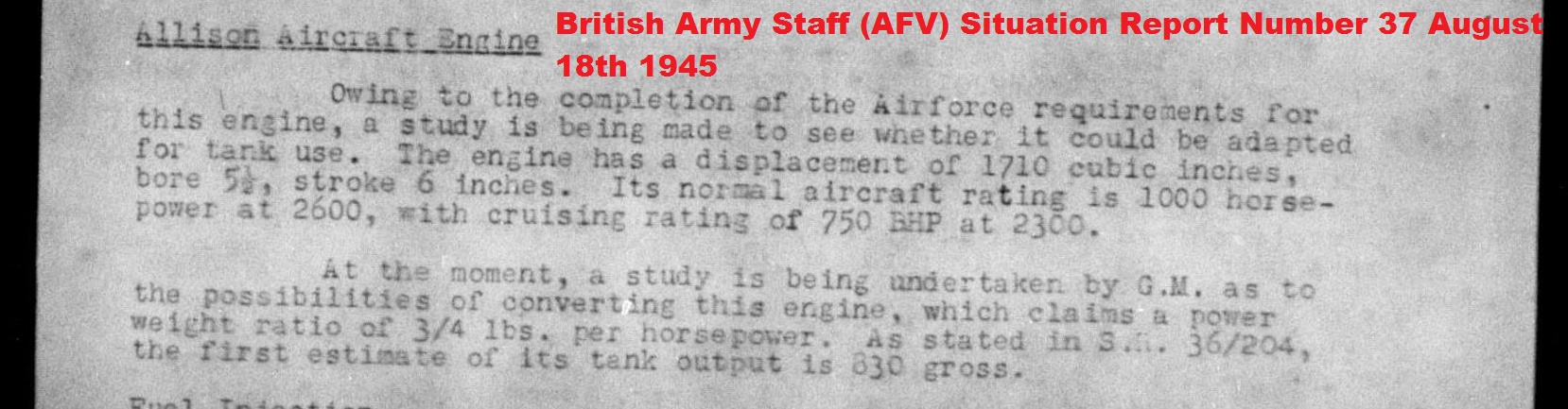

The V8 certainly was a very strange choice for the T2X family of medium tanks, especially as they became heavier with T25/M26. The whole point was to move away from Sherman's ideas, yet the opportunity wasn't taken to have a genuine quantum upgrade in power from the start. Either the 600-650 hp Packard or the 750 hp Ford V12 would have been much more suitable and may even have avoided some breakdowns caused by insufficent power, on top of making the M26 a true late war medium/battle tank like the Panther and Centurion.

Let alone the T28/95 superheavy tank which kept the V8 with a way greater weight!

the VVSS COULD take the extra weight... the US Army TOLD the UK that it could. But, a big but, that the UK could have extra side armor (1.5 inches to make it 3 inches) or additional armor on the front. But that they could not have both. I'll find the note its from 1942.

It can go up to around 92,000 lbs as there was a proposed M4A3E2 with additional armor at that weight using VVSS. That said, it is severe abuse. HVSS didn't hold up well at 102,000 lbs with a T26 turret over 1000 miles. They lost a few springs and road wheels.

The BAS Reports are not user friendly and I have been poking away at them for several years.

===============================================

>>"The V8 certainly was a very strange choice for the T2X family of medium tanks"<<

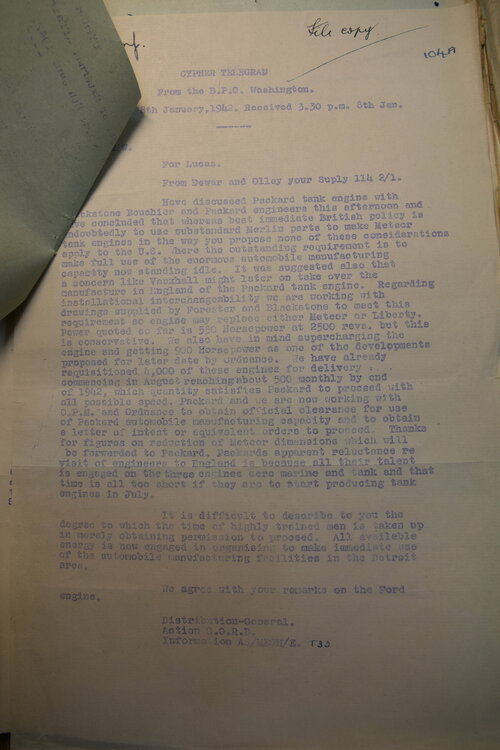

Devers wanted it in everything. Its why you see it being shoved in T14, the T20, and even the M18(specs drawn up) as well as in UK designs. There was a bit of a snag. It wouldnt be refined and decently reliable until mid 43 and production capacity was not great.

=

=

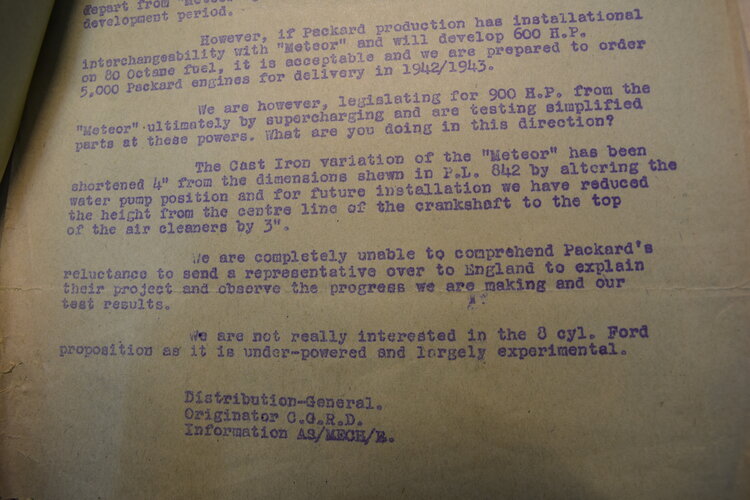

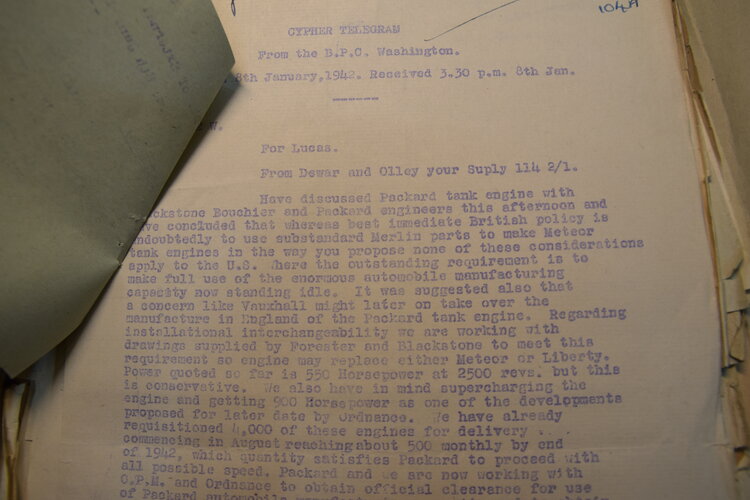

In March of 1943 Ford was told to increase production of the Ford GAA Engine to 600 engines per month. The increase in production was approved by the Ordnance Branch while development of the engine continued to be ongoing. However the British noticed that critical materials such as aluminum was going to affect the program and as such commented that the substitution for aluminum with cast iron was far more likely now (March 1943) than ever before. The British then hoped that with the order to increase production it would provide for a stable outlook in production for the next six months. As a result they hoped that they would be able to negotiate with Armored Force and Ordnance for a percentage of the monthly production run and get assistance with starting an Ford GAA line in the United Kingdom. General Devers agreed, as representing the Armored Force, that month to lower his demands for universal application of the Ford engine to all types of Armored Vehicles

[1].

[1] BAS 9 Page 011 Paragraphs 25 Ford V8 GAA March 1943.

=============================================

========================

======================== Timeline ==============

January 1943 360 per month engines or 11.6129 per day

[1].

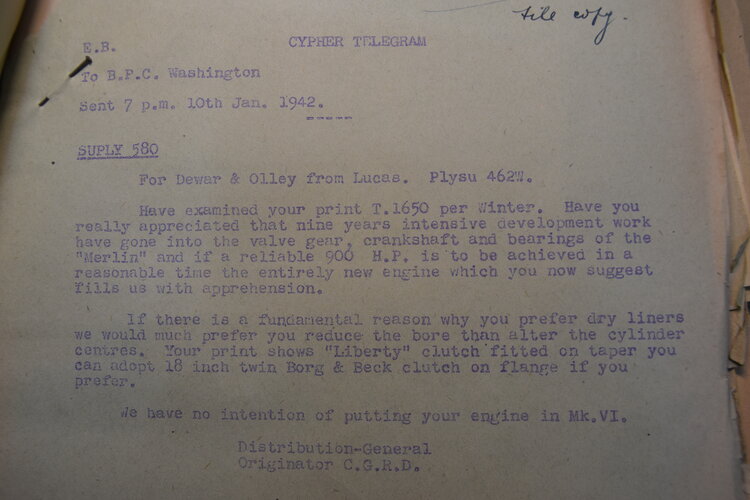

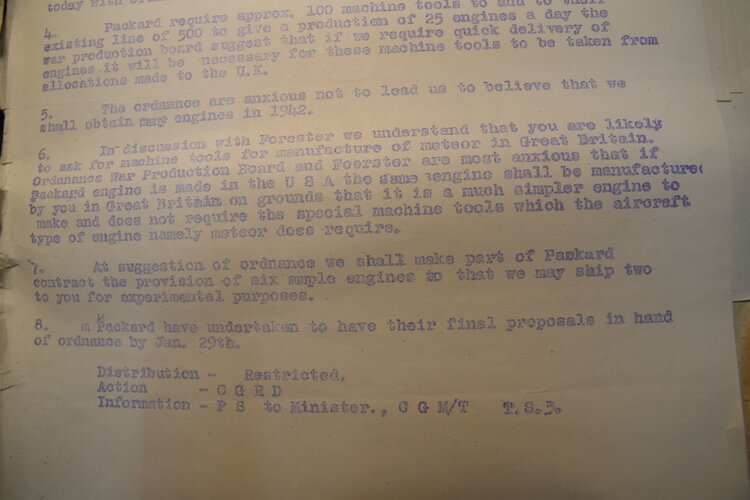

---U.S. Armed Forces were insistent in receiving Ford engines in M4A3 tanks and that, with production being low at 360 engines per month, the British and Russian requirements for the engine cannot be met until production reaches 2,000 engines per month. It was estimated that to bring production up to 2,000 per month would require, outside of Aluminum requirements, no less than 475 Machine Tools and 11,000,000 US Dollars for their purchase. A decision to make an Cast Iron model of the GAA was noted to ease Aluminum requirements for the engine but outside of the proposal nothing more was mentioned. This is all on top of the problem that Tanks and Tank Components have a lower priority compared to Aircraft. In view of all of the factors involved it was not expected that production would hit 2,000 engines a month before the end of the year .

February 1943 450 per month engines or 16.0714 per day. (Estimated in February 1943)

[2]

---From February 1943 onwards 600 per month is wanted. The 600 in June represented the total output which Ford can manage with the machine tools they have bought to date (Feb 1943), but which have not yet been received in their entirety

[3].

March 1943 300 per month engines or 9.6774 per day. (Estimated in February 1943)

[4]

---March 1943 Ford told to increase production to 600 per month

[5].

---From May 1943 onwards 600 per month is planned

[6].

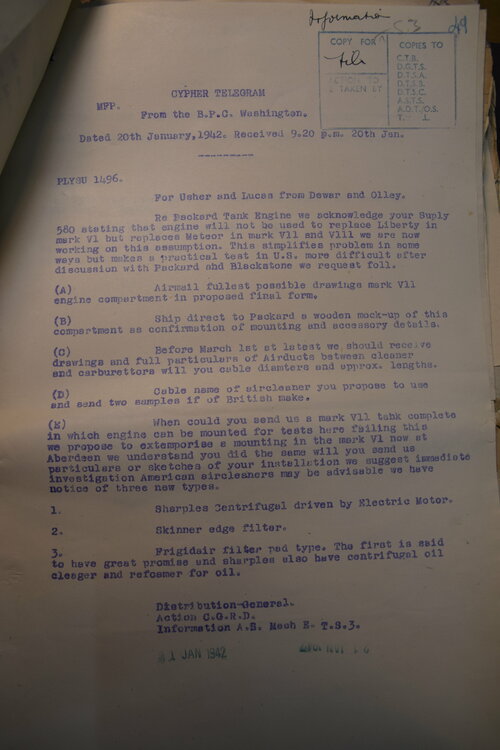

May 1943 Tank Automotive Center (TAC) estimates Ford could produce 750 engines per month.

---May 1943 Markland estimates Ford could produce 900 engines per month.

June 1943 600 per month engines or 20 per day. (Estimated in February 1943)

[7]

---June 1943 Ford engine production cannot be stepped up quickly enough over the previously mentioned limit of 900 engines per month of which the Ford plant is capable

[8].

October 1943 Production is 600 and it is planned that Continental may make some 200 engines per month

[9].

January 1944 775 per month or 25 per day (31 day month). Planned to increase to 32 and then 40 per day. Lincoln factory

[10]. 992 and 1,240 per month respectfully(Author).

February 1944 812 engines per month or 28 engines per day

[11].

April 1944 1,040 engines per month

[12].

[1] BAS 7 Page 014 Paragraphs 17 and 18 January 1943

[2] BAS 8 Page 020 Paragraphs 18 Ford V8 GAA Feb 1943.

[3] BAS 8 Page 020 Paragraphs 18 Ford V8 GAA Feb 1943.

[4] BAS 8 Page 020 Paragraphs 18 Ford V8 GAA Feb 1943.

[5] BAS 9 Page 011 Paragraphs 25 Ford V8 GAA March 1943.

[6] BAS 8 Page 020 Paragraphs 18 Ford V8 GAA Feb 1943.

[7] BAS 8 Page 020 Paragraphs 18 Ford V8 GAA Feb 1943.

[8] BAS 12 Page 035 Para 066 June 1943 (Production Figures)

[9] BAS 16 Page 042 Para APP A October 1943.

[10] BAS 18 Page 037 Para 052 Ford GAA January 1944.

[11] BAS 19 Page 035 Para 44 February 1944.

[12] BAS 21 Page 025 Para 29. April 1944