Graugrun

ACCESS: Top Secret

- Joined

- 17 May 2011

- Messages

- 854

- Reaction score

- 1,196

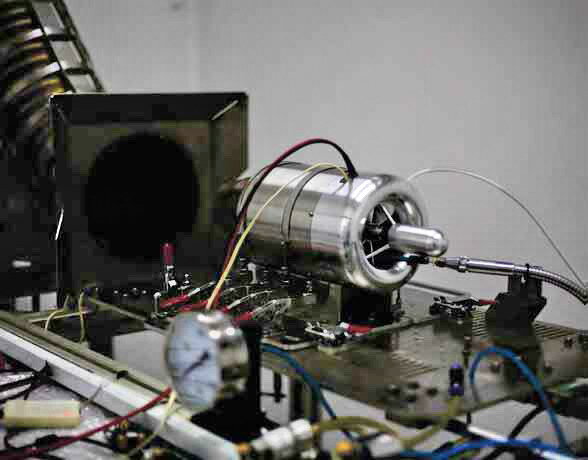

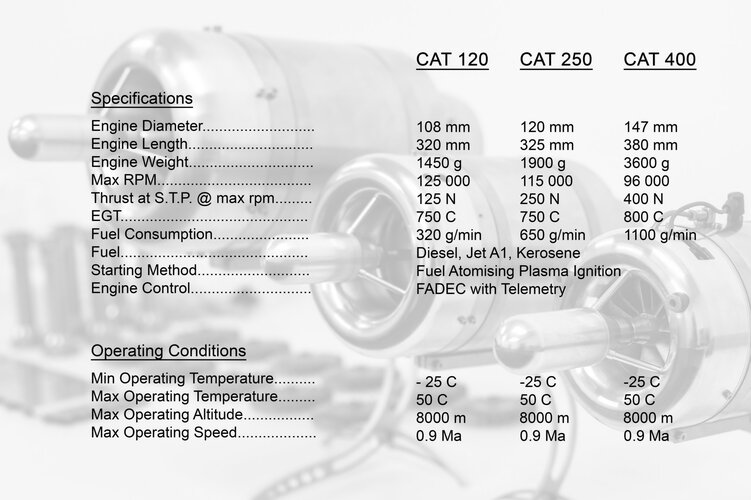

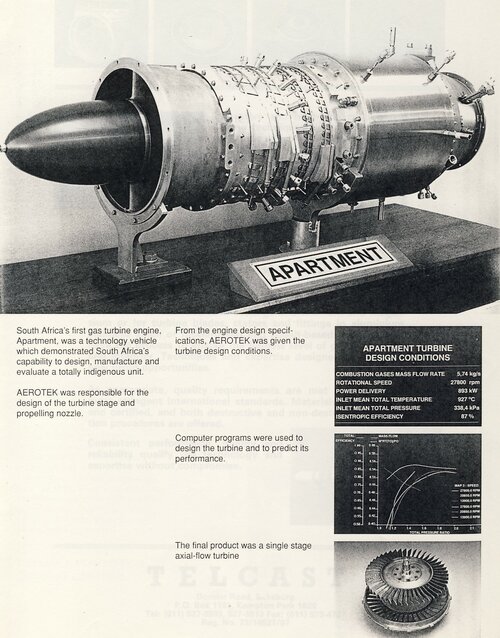

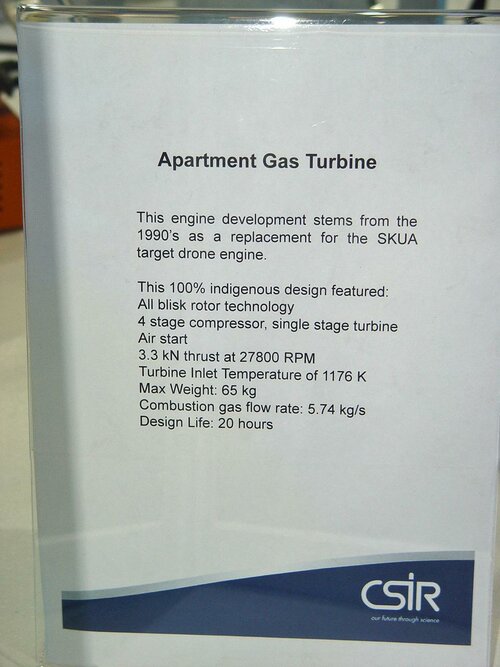

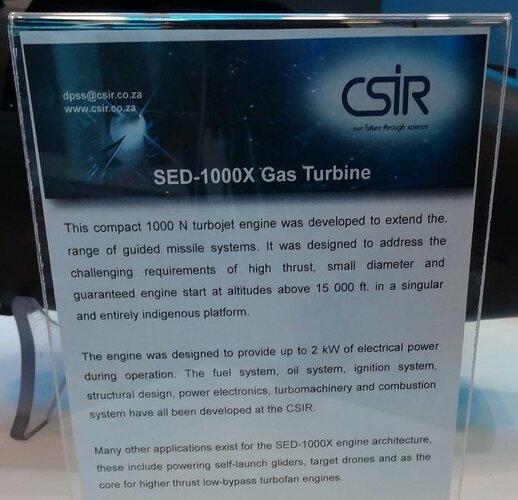

A collection of various South African propulsion projects, prototypes and ideas. Bits and pieces of these projects have been scattered around this site, I think it's time to gather them into one place for easy reference. Starting with this article on Cape Aerospace Technologies (CAT) designs. While their micro turbine designs geared mostly for hobby enthusiasts useage, they are scaling them up to allow for more serious military use.

They have some interesting claims to fame (others with in depth knowledge of the micro gas turbine industry can confirm this or not). These include:

1. Developing the first single fuel electric start system for micro gas turbines in the world in 1999.

2. Developing the world’s first plasma ignition system for micro gas turbines (outperforming standard glowplugs).

3. The fastest micro turbojet startup time on the market: six seconds from 0 rpm to idle (32 000 rpm), compared to the industry’s best at 25-40 seconds. Going from idle to full throttle takes three seconds.

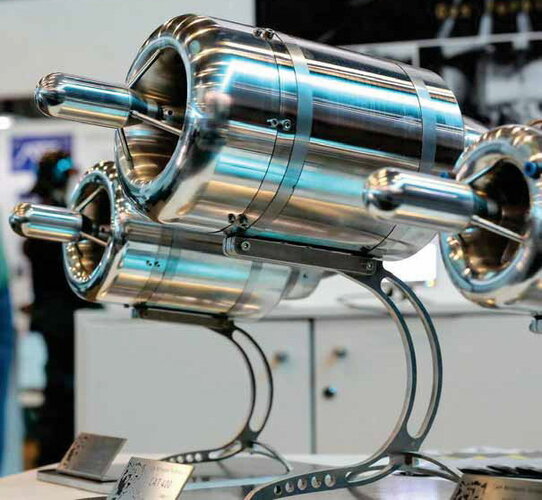

They are now heading for 800N and 1400N thrust designs (around 1000N becomes interesting for military PGM use). Strangely enough they are also working on a concept 1kN rocket design, that if successful, they hope to scale up for use in LEO capable delivery systems (Micro satellite launches I assume).

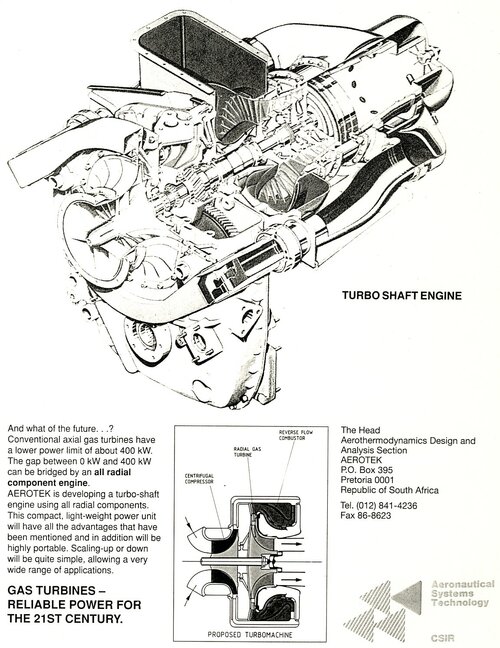

When I spoke to the Managing Director at AAD in 2018 he already had the 400N thrust working model on his stand - so I'm not sure why the article states that it is still in development. He had a very close working relationship with the CSIR head who developed (a seperate series) of Micro Gas Turbines, that were then taken over (IP bought) by the UAE - more on that later.

https://www.defenceweb.co.za/aerosp...new-projects-for-cape-aerospace-technologies/

They have some interesting claims to fame (others with in depth knowledge of the micro gas turbine industry can confirm this or not). These include:

1. Developing the first single fuel electric start system for micro gas turbines in the world in 1999.

2. Developing the world’s first plasma ignition system for micro gas turbines (outperforming standard glowplugs).

3. The fastest micro turbojet startup time on the market: six seconds from 0 rpm to idle (32 000 rpm), compared to the industry’s best at 25-40 seconds. Going from idle to full throttle takes three seconds.

They are now heading for 800N and 1400N thrust designs (around 1000N becomes interesting for military PGM use). Strangely enough they are also working on a concept 1kN rocket design, that if successful, they hope to scale up for use in LEO capable delivery systems (Micro satellite launches I assume).

When I spoke to the Managing Director at AAD in 2018 he already had the 400N thrust working model on his stand - so I'm not sure why the article states that it is still in development. He had a very close working relationship with the CSIR head who developed (a seperate series) of Micro Gas Turbines, that were then taken over (IP bought) by the UAE - more on that later.

https://www.defenceweb.co.za/aerosp...new-projects-for-cape-aerospace-technologies/

Attachments

Last edited: