If I'm posting this in the wrong board, please tell me, I'll repost the question in the right place.

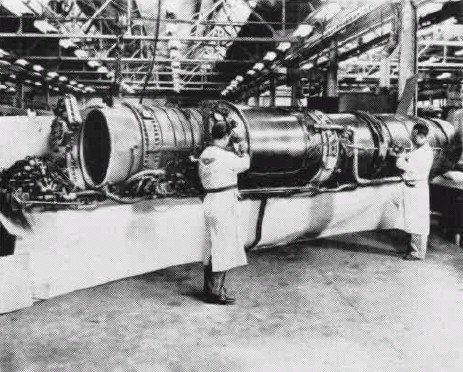

A question that comes and goes to my mind is why those engines failed, dooming or almost dooming many projects with them. The J40 and J46 failures took Westinghouse out of the jet engine business, forcing some aircraft either to take engines not suited to them(F3H Demon and the J71), or languish with underpowered engines(F7U Cutlass and the J34). What I've found about the J40 seems to imply the afterburner was the problem; the engine without it passed its tests(not without trouble), but the J40-WE-8, that had the afterburner to meet its high performance goals was a miserable failure. The J46 is mentioned only in passing together with the J40 failure, with no clue on what went wrong.

The J65's problem definitely was the afterburner; the un-reheated engine seems to have done OK on the B-57, A-4, F-84F, FJ-4 and other aircraft I doubtlessly I'm forgetting to mention, but the afterburner on the F11F engine simply didn't give the needed thrust, making the Tiger barely supersonic. The J67, also a British engine(Olympus) built under license by Wright, was considered for many projects, but eventually none used it, those that went forward turning to P&W and the J75 for their needs.

So, what exactly went wrong to each of these engines?

A question that comes and goes to my mind is why those engines failed, dooming or almost dooming many projects with them. The J40 and J46 failures took Westinghouse out of the jet engine business, forcing some aircraft either to take engines not suited to them(F3H Demon and the J71), or languish with underpowered engines(F7U Cutlass and the J34). What I've found about the J40 seems to imply the afterburner was the problem; the engine without it passed its tests(not without trouble), but the J40-WE-8, that had the afterburner to meet its high performance goals was a miserable failure. The J46 is mentioned only in passing together with the J40 failure, with no clue on what went wrong.

The J65's problem definitely was the afterburner; the un-reheated engine seems to have done OK on the B-57, A-4, F-84F, FJ-4 and other aircraft I doubtlessly I'm forgetting to mention, but the afterburner on the F11F engine simply didn't give the needed thrust, making the Tiger barely supersonic. The J67, also a British engine(Olympus) built under license by Wright, was considered for many projects, but eventually none used it, those that went forward turning to P&W and the J75 for their needs.

So, what exactly went wrong to each of these engines?