seruriermarshal

ACCESS: Top Secret

- Joined

- 4 May 2008

- Messages

- 1,180

- Reaction score

- 574

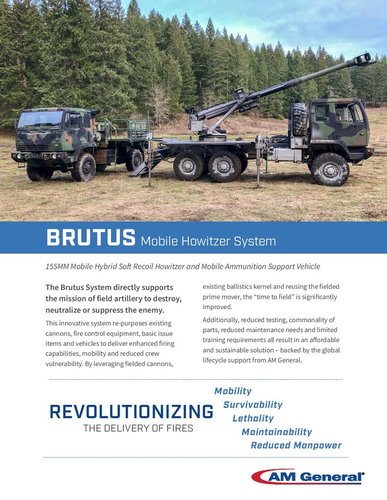

The U.S. Army developed an experimental 155mm truck-mounted howitzer, called the Brutus.

The photos of experimental truck-mounted howitzer were published on the Facebook page of the 75th Field Artillery Brigade (artillery brigade in the United States Army) on 26 October.

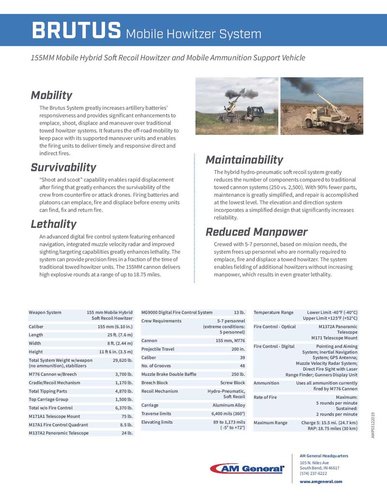

The Brutus is a 155mm truck-mounted howitzer for increased mobility and enhanced firing capabilities. Experimental 155mm howitzer installed on an FMTV 6X6 truck chassis.

Howitzer is capable of using a wide range of ammunition for deployment against protected and unprotected targets, to create counter-mobility obstacles to block the manoeuvres of enemy armoured forces and to obscure or illuminate an area.

No further details on the type of howitzer have been released.

The U.S. Army interested in new, more mobile, lightweight artillery pieces.

Early, Army’s officials showed interest in 105mm Mobile Weapon System (105MWS), also dubbed HAWKEYE by AM General, consists of one 105mm cannon mounted at the rear on HUMVEE light tactical vehicle chassis. Maybe U.S Army is also interested in upgrades for or modification to its existing weapons, especially lightweight 155mm cannons, or various types of self-propelled guns.

Having that kind of firepower on-call is immensely important for the Army’s light infantry, especially when conducting independent operations where they might not have the guarantee of support from other services or even other elements within the Army.

https://defence-blog.com/army/u-s-army-unveils-experimental-155mm-truck-mounted-howitzer.html

The photos of experimental truck-mounted howitzer were published on the Facebook page of the 75th Field Artillery Brigade (artillery brigade in the United States Army) on 26 October.

The Brutus is a 155mm truck-mounted howitzer for increased mobility and enhanced firing capabilities. Experimental 155mm howitzer installed on an FMTV 6X6 truck chassis.

Howitzer is capable of using a wide range of ammunition for deployment against protected and unprotected targets, to create counter-mobility obstacles to block the manoeuvres of enemy armoured forces and to obscure or illuminate an area.

No further details on the type of howitzer have been released.

The U.S. Army interested in new, more mobile, lightweight artillery pieces.

Early, Army’s officials showed interest in 105mm Mobile Weapon System (105MWS), also dubbed HAWKEYE by AM General, consists of one 105mm cannon mounted at the rear on HUMVEE light tactical vehicle chassis. Maybe U.S Army is also interested in upgrades for or modification to its existing weapons, especially lightweight 155mm cannons, or various types of self-propelled guns.

Having that kind of firepower on-call is immensely important for the Army’s light infantry, especially when conducting independent operations where they might not have the guarantee of support from other services or even other elements within the Army.

https://defence-blog.com/army/u-s-army-unveils-experimental-155mm-truck-mounted-howitzer.html