“Boeing was doing all kinds of things, everything you can imagine, to reduce cost, including moving work from Puget Sound, because we’d become very expensive here,” said Rick Ludtke, a former Boeing flight controls engineer laid off in 2017. “All that’s very understandable if you think of it from a business perspective. Slowly over time it appears that’s eroded the ability for Puget Sound designers to design.”

Rabin, the former software engineer, recalled one manager saying at an all-hands meeting that Boeing didn’t need senior engineers because its products were mature. “I was shocked that in a room full of a couple hundred mostly senior engineers we were being told that we weren’t needed,” said Rabin, who was laid off in 2015.

The typical jetliner has millions of parts -- and millions of lines of code -- and Boeing has long turned over large portions of the work to suppliers who follow its detailed design blueprints.

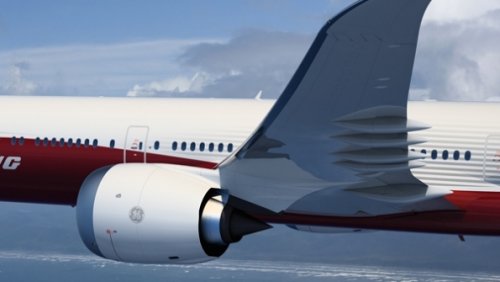

Starting with the 787 Dreamliner, launched in 2004, it sought to increase profits by instead providing high-level specifications and then asking suppliers to design more parts themselves. The thinking was “they’re the experts, you see, and they will take care of all of this stuff for us,” said Frank McCormick, a former Boeing flight-controls software engineer who later worked as a consultant to regulators and manufacturers. “This was just nonsense.”