"Boeing considers wingtips that on its next big jet"

Seattle Times November 5, 2012

by Dominic Gates, Seattle Times aerospace reporter

Source:

http://seattletimes.com/html/businesstechnology/2019614451_777x06.html

Seattle Times November 5, 2012

by Dominic Gates, Seattle Times aerospace reporter

Source:

http://seattletimes.com/html/businesstechnology/2019614451_777x06.html

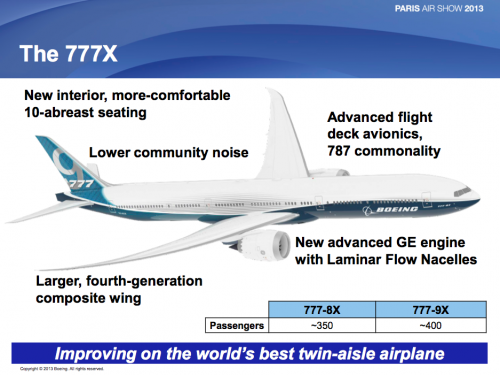

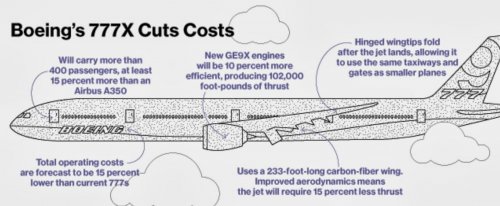

For the immense wings planned for the 777X, engineers at Boeing are studying a design in which the wingtips fold upward to reduce the jet's span when it sits at the gate or rolls along a taxiway.

Passengers looking out the 777X's window would see each wingtip smoothly unfold to the horizontal as the jet lines up for takeoff on the runway.

Just as the hump on a 747 gives that Boeing jet a distinctive look, the folding wingtips would make the next version of the best-selling, twin-aisle 777 instantly recognizable to the general public.

"There's a coolness factor ... It's sort of a sci-fi-like thing," said a veteran Boeing engineer, speaking on condition of anonymity because he's not authorized to speak publicly on the subject. "But to those in the industry, it's not so surprising."

The engineer emphasized that the precise design of the 777X won't be finalized until around 2014, with possible tweaks to design elements even later.

But he said some kind of foldout wingtip looks almost certain, given the very large wingspan Boeing needs to provide extra fuel efficiency.

Asked about the possibility of folding wingtips, Boeing spokeswoman Karen Crabtree said the company is still "exploring all technologies" and evaluating the trade-offs they involve.

In fact, it isn't a new idea. In 1995, Boeing obtained a patent for a folding wingtip design on the original 777, which had a 200-foot wingspan.

That mechanism was even built and tested — the full-scale model used then is on display at the Museum of Flight Restoration Center at Paine Field in Everett. But no airline ever bought this option.

An old idea revisited

The idea has been revived now because of the oversized wingspan envisaged for the new 777X, the next version of Boeing's large twinjet widebody.

Targeted to enter service by the end of this decade, it will feature new, fuel-efficient engines and thin, aerodynamic wings that are similar to those of the 787 Dreamliner and likely made from the same carbon-fiber-reinforced plastic composite.

According to reports in the trade press, engineers are looking at a wingspan as wide as 233 feet — about nine feet wider than Boeing's bigger jumbo jet, the 747-8.

On the 1995 design, the outer 21 feet of each wing was to fold upward on a hinge.

In the design now under consideration, however, the wingtip section that folds need be no more than about 10 feet on each wing to avoid airport restrictions.

Most large airports in the world can accommodate airplanes conforming to an international standard referred to as Code E — which limits the wingspan to 213 feet.

Anything wider creates problems.

The Airbus A380 double-decker jet, with a wingspan of 262 feet, is a category higher, Code F.

Airports have had to widen runways and taxiways and build larger gates to accommodate that massive jet. But the A380 is a niche airplane serving a relatively small number of megacity airports.

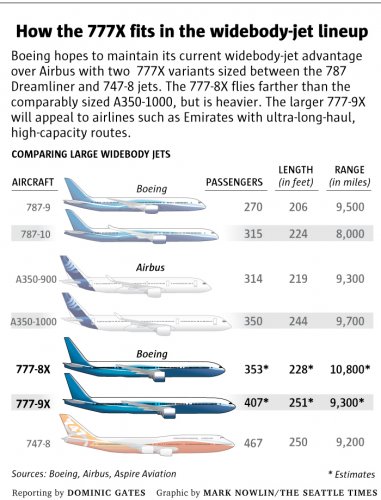

Boeing intends to build many more 777Xs, and to sell well they must be able to land at hundreds of airports such as Seattle-Tacoma International.

Emirates, Boeing's largest 777 customer, took delivery of the 1,000th Boeing 777 in March.

The plan to revamp the highly profitable 777 is intended to extend its life to at least a further 1,000 jets, said Emirates President Tim Clark.

He said Boeing knows it needs "a very large wing with a big span" to make it capable of the ultra-long-range missions Emirates wants it to fly.

"The range and aerodynamic quality of this aircraft is all about the wing," Clark said.

Yet, at the same time, he said, Boeing must also find a way to reduce the wingspan at the airport so the jet can be accommodated without infrastructure changes.

"If they are going to produce 2,000 of these aircraft, it cannot be a Code F aircraft," said Clark. "It will not be compatible for the majority of airports in the world."

Boeing's Crabtree said the 777X development team is studying configurations "that exceed today's 777 wingspan," but that no information on ongoing studies or any details of airplane configuration are ready for release.

Large market

When Boeing developed its new 747-8 jumbo jet — which has a wingspan of 225 feet and so is technically a Code F airplane — it solved the problem by doing special safety studies at each airport where the jet might land, coupled with operational restrictions where necessary.

With that work done, the 747-8 is allowed to operate at Code E airports. But again, only a few hundred 747-8s will ever be built.

For a new 777, with an even larger wingspan and many more of the jets operating at airports worldwide, such an airport-by-airport solution seems impractical.

Emirates chief Clark said he doesn't yet know what Boeing's final 777X design will be, but "suffice it to say, they will make it a Code E airplane."

"They have to think out of the box, and they know that," Clark said.

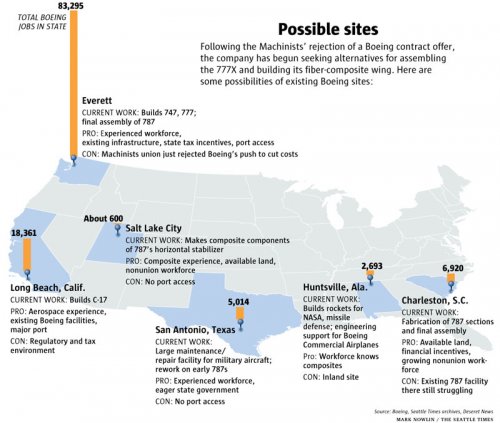

The veteran Boeing engineer said much of the research and development for the 777X has to be completed next year.

"I think that we'll offer it is guaranteed," he said about the folding wingtip.