"The key task of the Factory of the Future is the formation of a complex of world-class competencies based on the integration of advanced production technologies and business models. The idea of the "Factory of the Future" implies maximum digitalization of production processes, reduction of costs and time for product design, as well as improvement of its quality through more accurate modelling," says Oleg Yevtushenko, executive director of Rostec State Corporation.

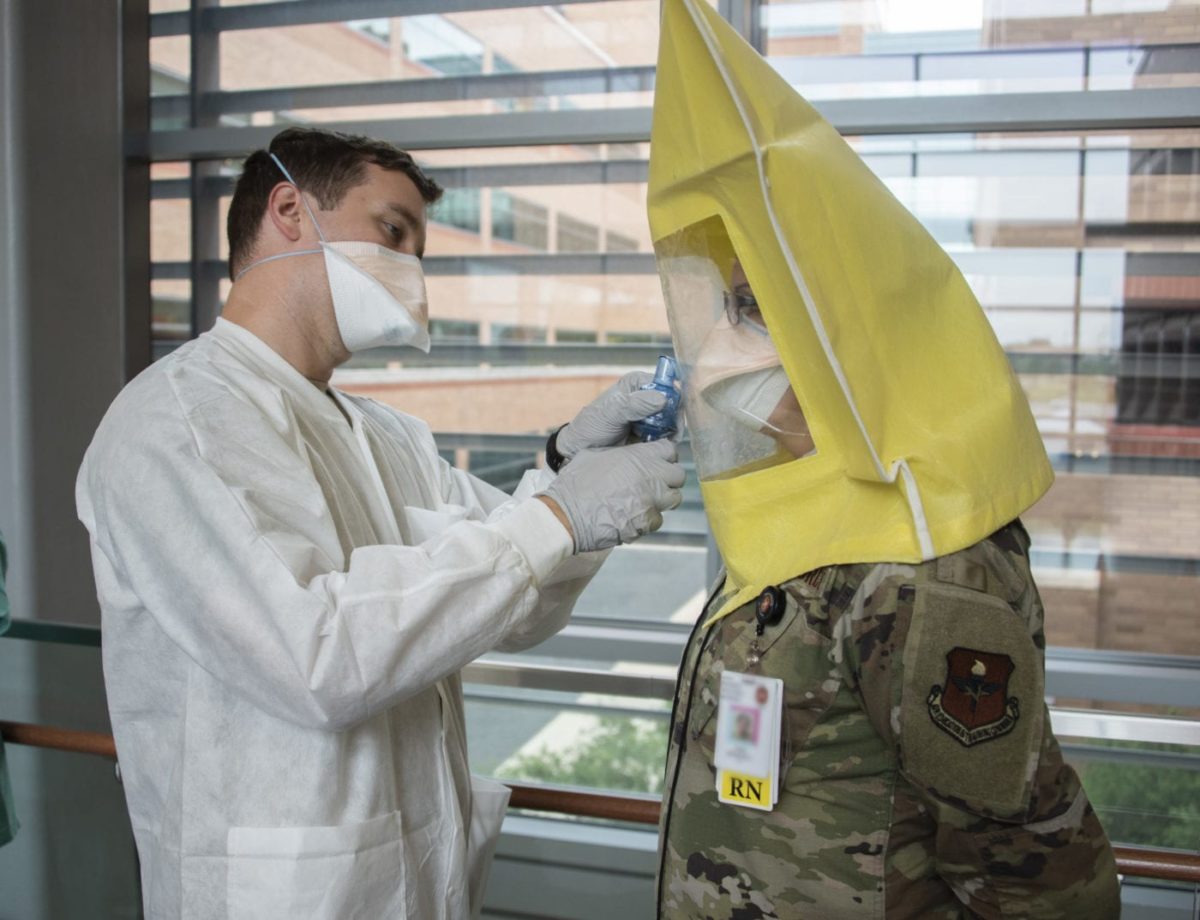

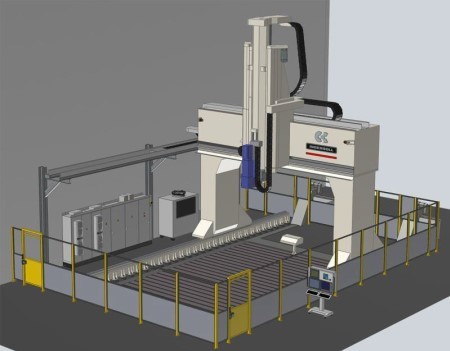

At the same time, digitalization implies not only the design stage of certain elements of the power plant in CAD systems, but also the introduction of a new bench base, the use of digital services to facilitate technical maintenance of equipment, and the integration of all machines into a single network.

The enterprises of the United Engine Corporation, a part of Rostec, were selected as the testing ground for the Factory of the Future, in particular, the concept is being implemented at UEC-Saturn.

“In the engine-building industry today there are practically no test benches that are controlled by analog methods, everything has been digitized long ago. For comparison, the old bench base under the control of operators could simultaneously monitor and control about a hundred parameters that the product produces. Digital control systems allow monitoring thousands of parameters simultaneously. This makes it possible to increase the accuracy and quality of the use of this technique ", - notes UEC production director Valery Teplov.

In addition, the use of additive technologies plays a significant role in the implementation of the "Factory of the Future" concept. These technologies, along with smart design and modelling, the integration of industrial facilities into a single Internet of things and high performance computing, are among the most advanced today.

The use of 3D printing has several key advantages when working on the design and manufacture of a product, including: customization at the request of the customer, increased product functionality, and market reactivity.

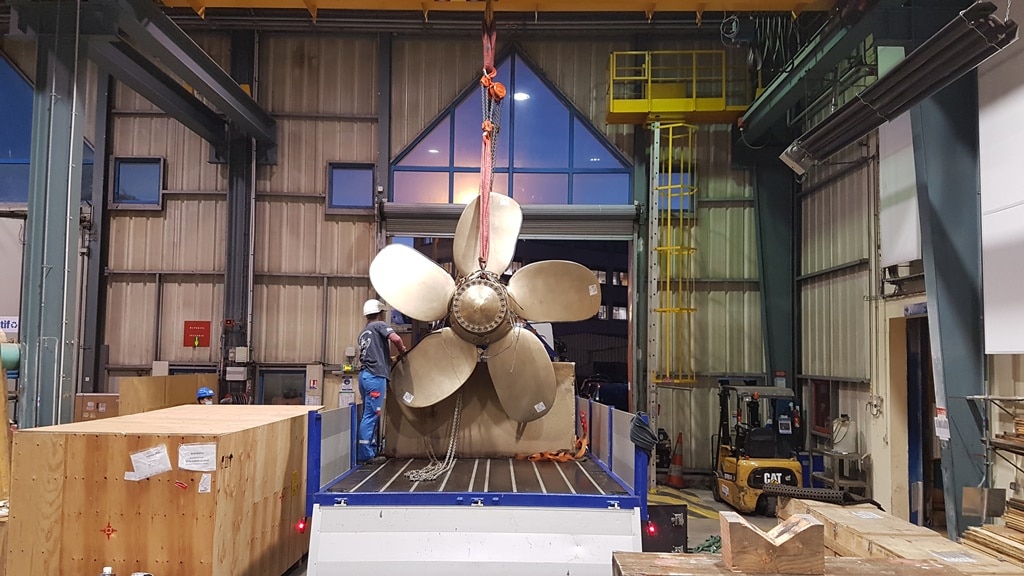

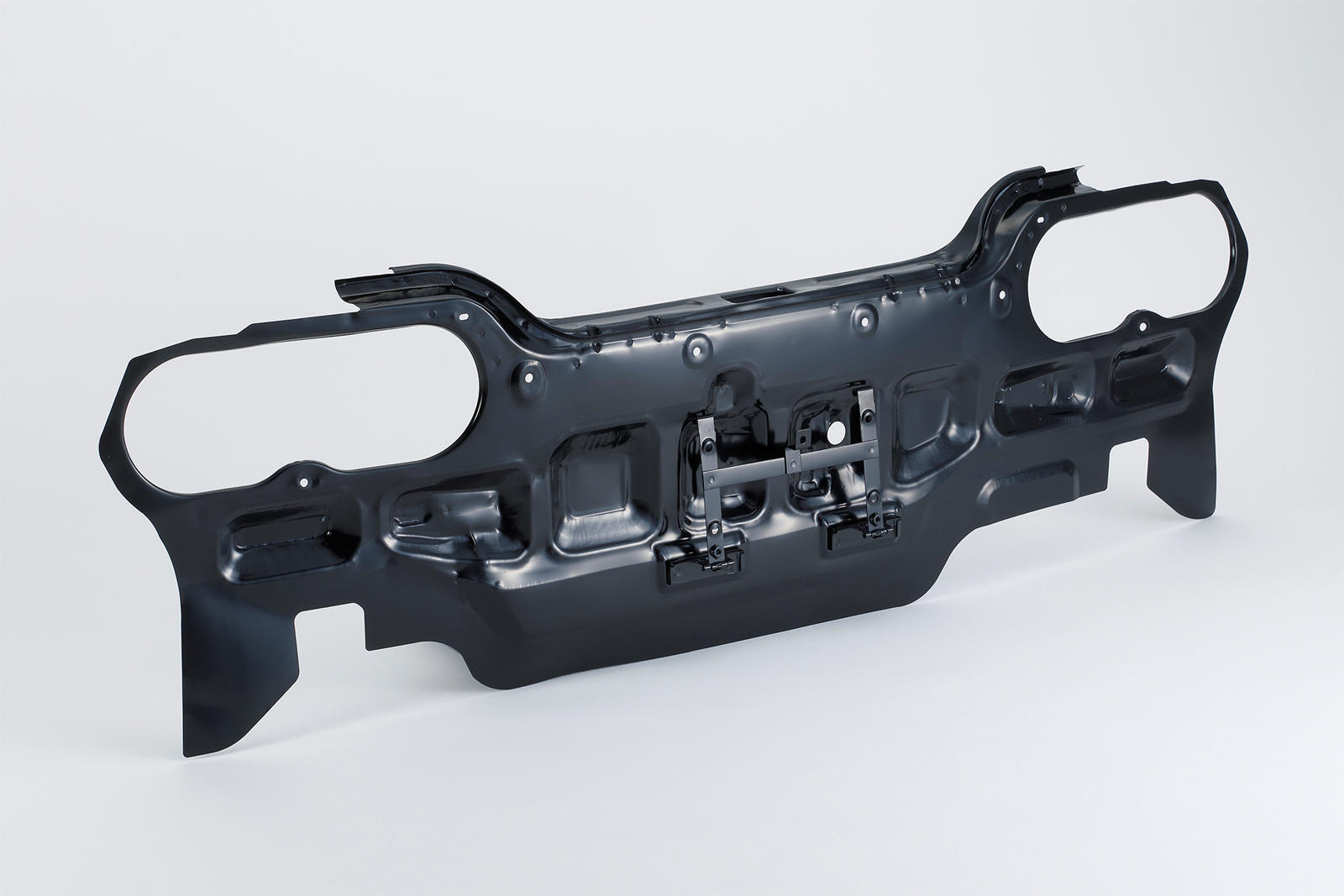

In new engines, up to 20% of the mass will be made up of parts designed and manufactured using additive technologies. Due to new design technologies, including through topological optimization, the number of parts and assembly units in engines will be reduced by more than half.

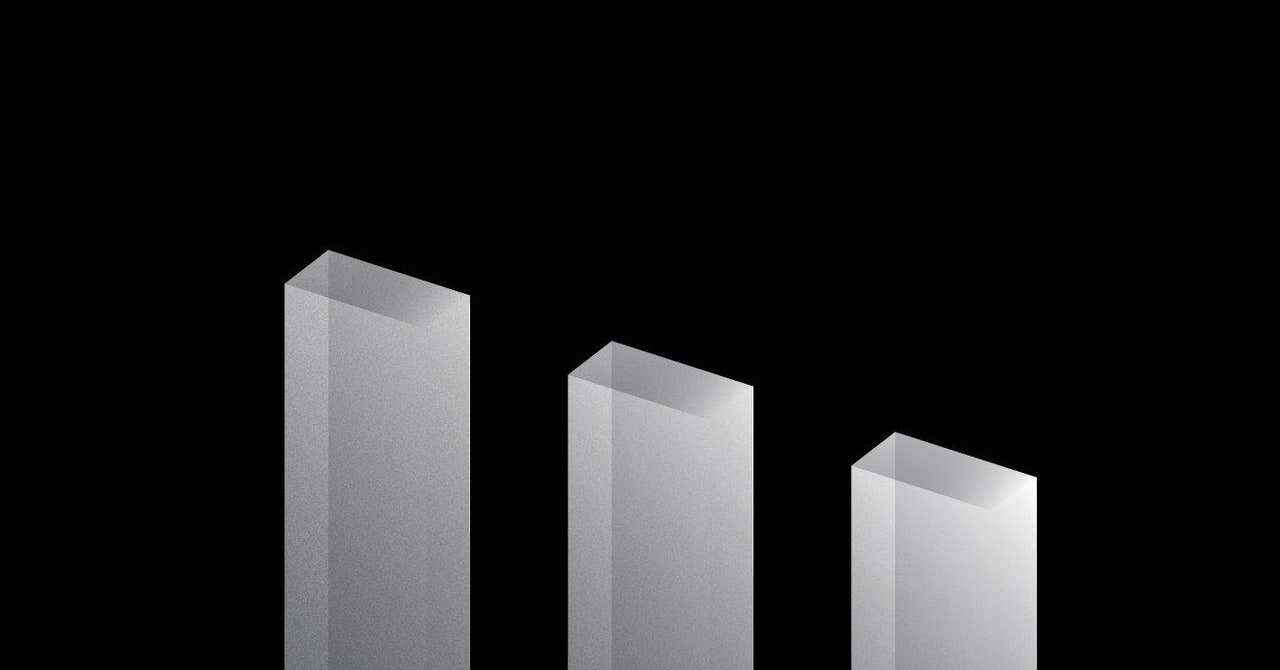

In turn, the reduction in the time and cost of technological preparation of production will reduce the development time of experimental parts manufactured by additive technologies by 80%, the production cycle of serial parts will be reduced by up to 3 times, and the manufacturing cost - by up to 2 times. Such an approach in aircraft engine building allows to significantly reduce the time needed to create units - up to 10 times.

“Additively, you can grow a combustion chamber prototype about ten times faster than traditional technologies. First, you would design special rigging, stamps [with the traditional method], then you would make a sheet from which you would form the appearance of the combustion chamber by various methods, then you would implement it all - put it into experimental work ... In general, the advantage is obvious,” - Teplov says.

The demand for this technology is confirmed by numbers - if in 2019, approximately 4.5 thousand parts were produced in the UEC in an additive way, then this year it is expected to be about 8.5 thousand. That is, almost a twofold increase.

hackaday.com