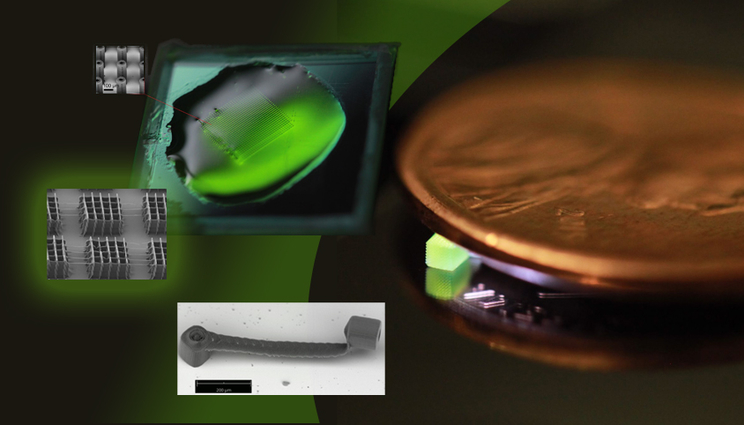

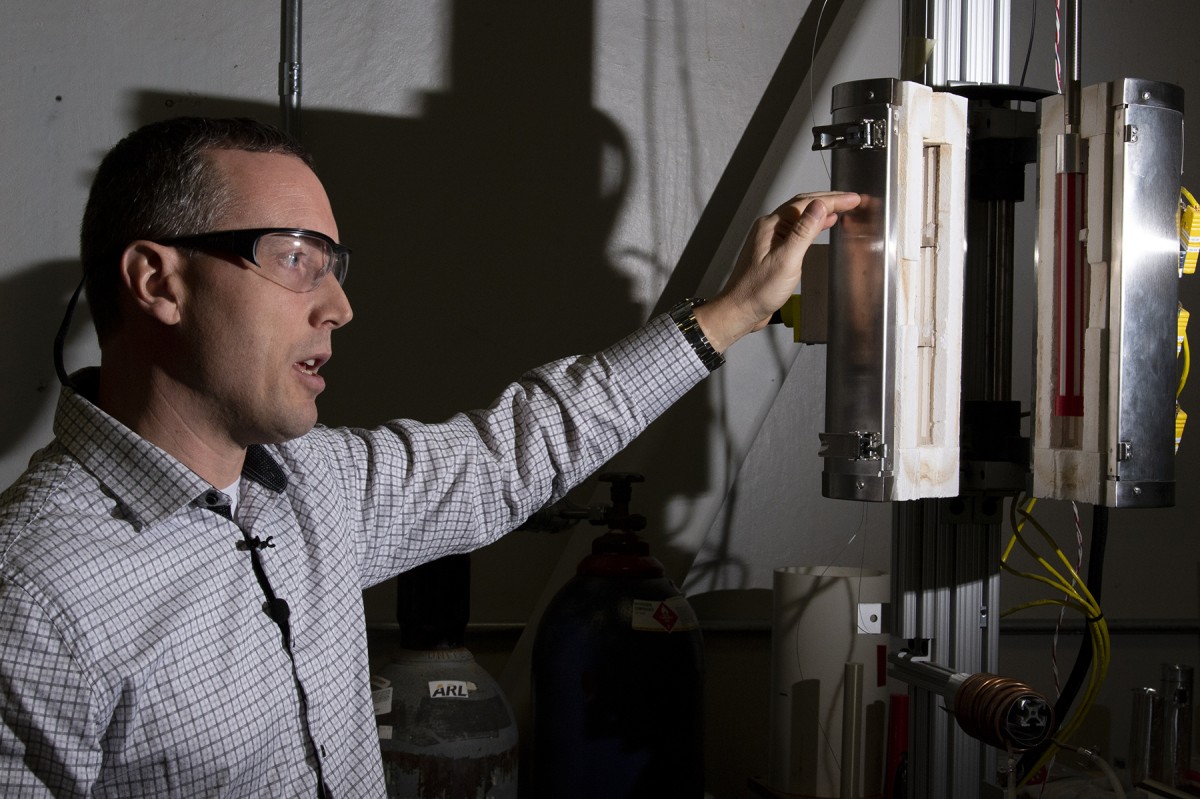

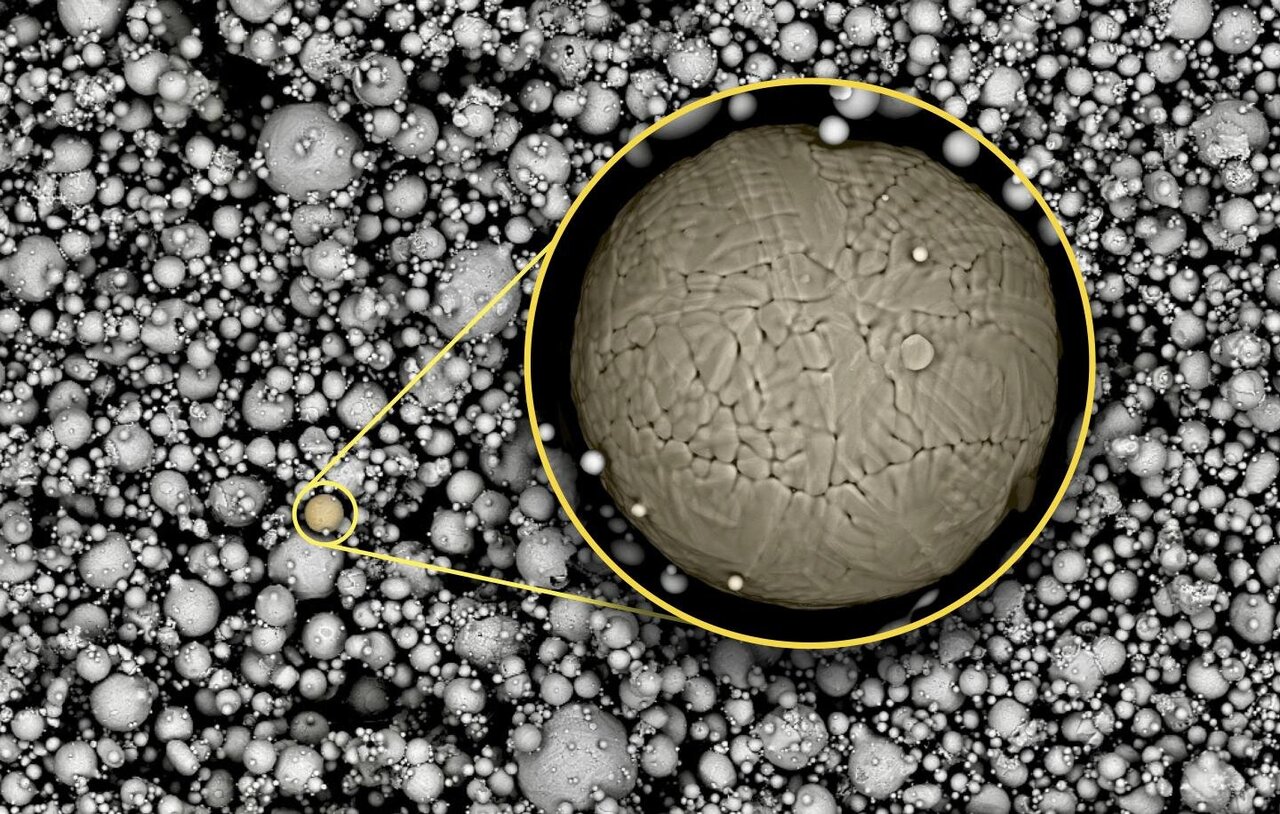

Challenged by the Army’s emerging NGCV requirements, the Army Research Laboratory is now working to engineer and build new, lightweight yet survivable vehicle parts such as brackets, turret components, propulsion systems and weapons, using “additive manufacturing” or 3D printing technology. In particular, the effort includes the exploration of lightweight metals such as titanium, titanium alloys and hybrid ceramic tile/polymer-matrix composites.

“Titanium is lightweight and has a specific strength to weight ratio. Titanium is half the weight of other metals currently in use," Dr. Brandon A. McWilliams, Materials Engineer, Lead for Metals Added Manufacturing, Army Research Lab, Combat Capabilities Development Command, Army Futures Command, told Warrior in an interview, Aberdeen Proving Ground, Md. "With additive manufacturing, the costs can come down and make business sense.”

Certain elements of lower-cost titanium have already been in use for several armored vehicle applications such as up-armor for the Abrams tanks and the Commander’s Hatch in the Bradley Infantry Fighting Vehicle. However, this integration has been minimal and largely peripheral. Army engineers working on future combat vehicles are now calling for more titanium for large and vital elements in combat vehicles, in part because 3-D printing can deliver it in a more efficient, lower-cost fashion.

Interestingly, using more titanium for military vehicles is emphasized and anticipated in a 1997

essay, entitled “Low-Cost Titanium Armors for Combat Vehicles.” The essay, published in JOM, states “future-vehicle hull and turret will have to be manufactured using more ballistically efficient materials than rolled homogeneous steel armor. Low-cost titanium, with its good mechanical, ballistic, and corrosion properties and acceptable fabricability, offers the overall best alternative to achieving this objective.”

www.foxnews.com

www.upi.com

www.upi.com

www.nextbigfuture.com

www.nextbigfuture.com

www.forbes.com

www.forbes.com