- Joined

- 9 October 2009

- Messages

- 21,969

- Reaction score

- 13,615

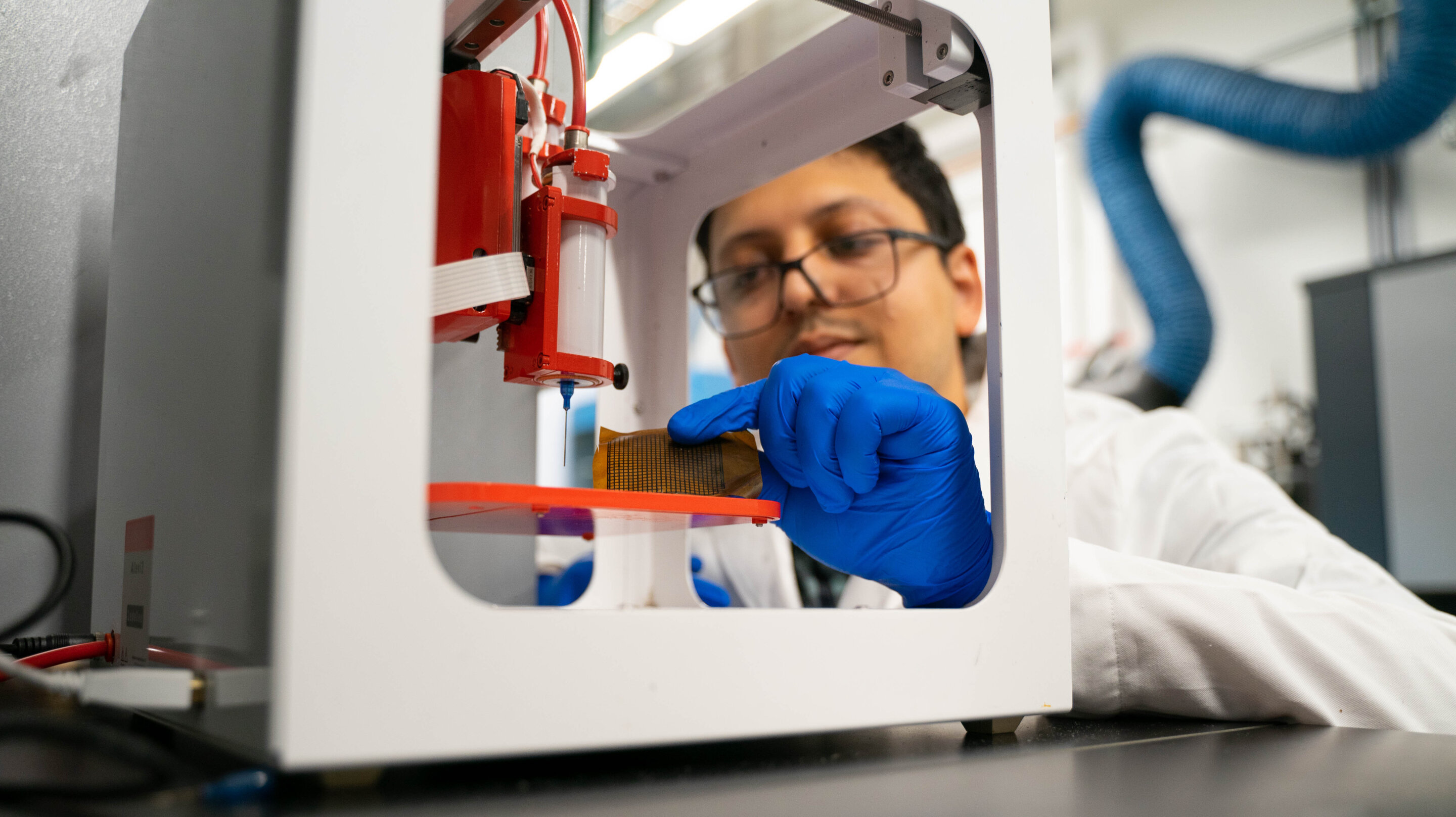

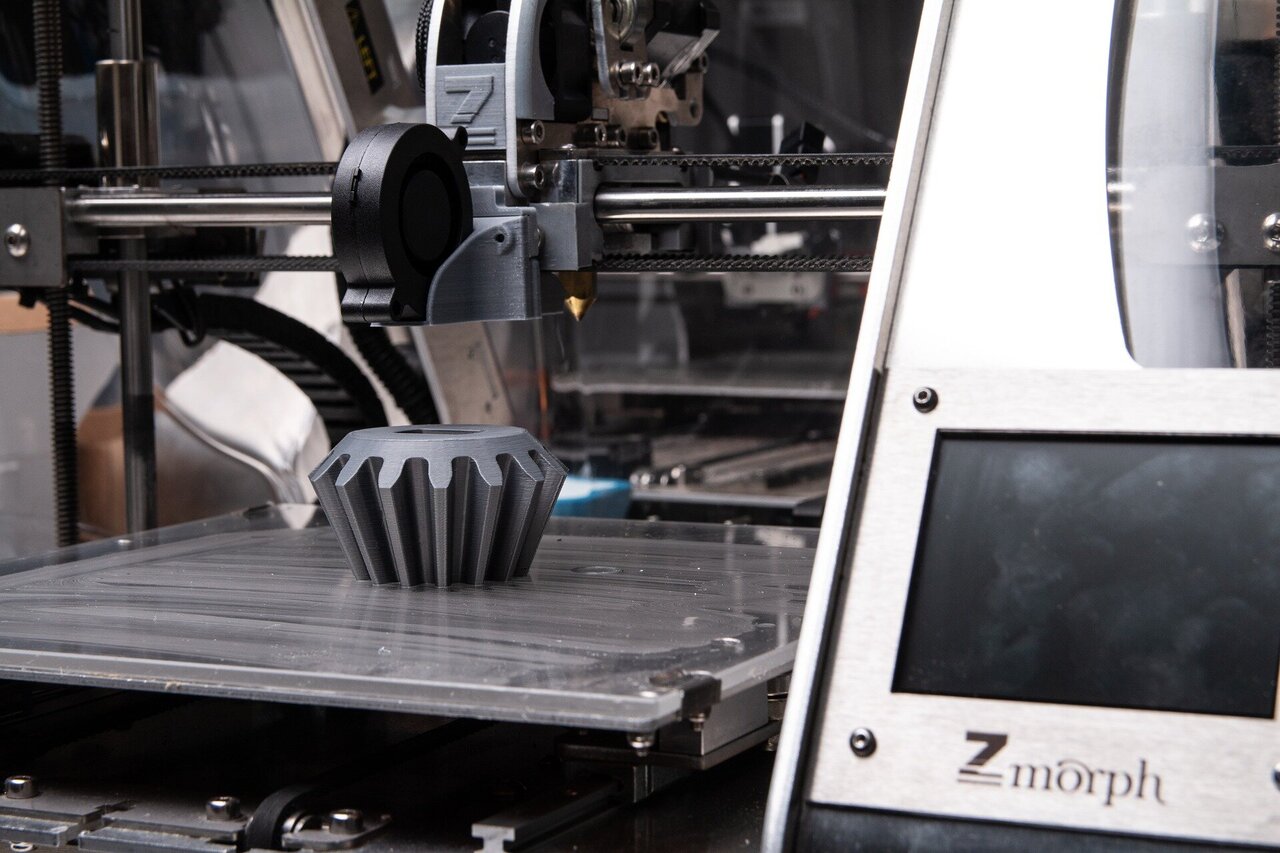

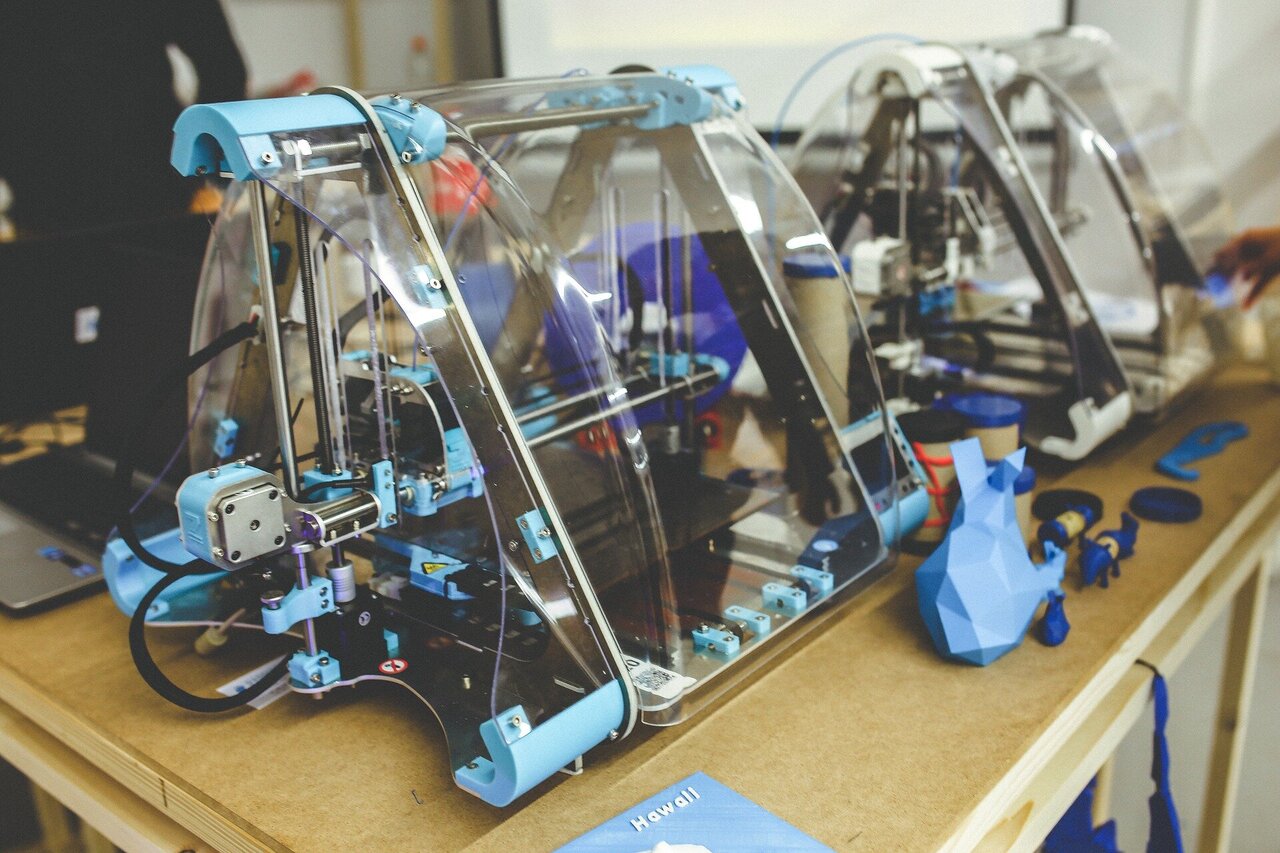

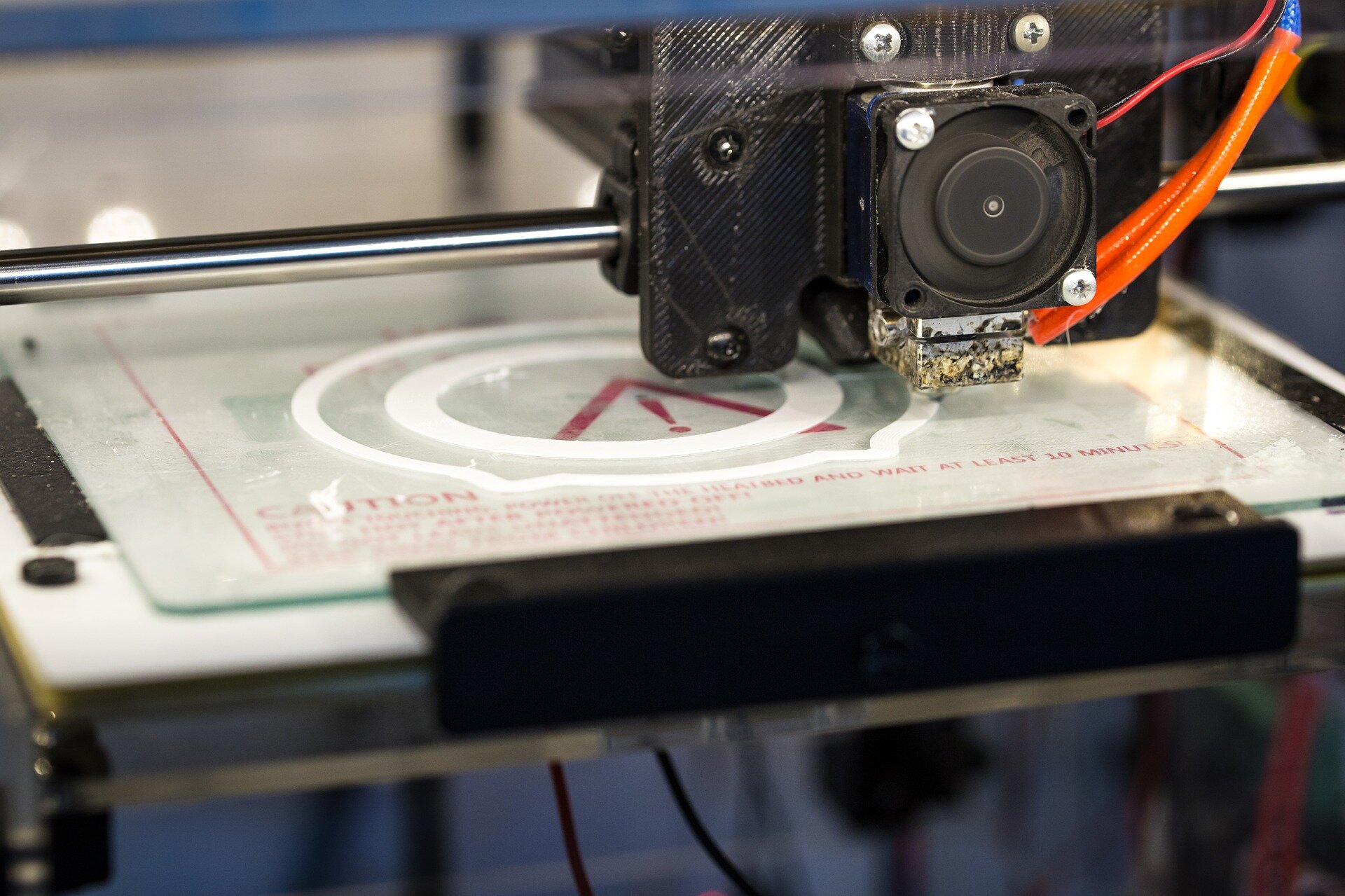

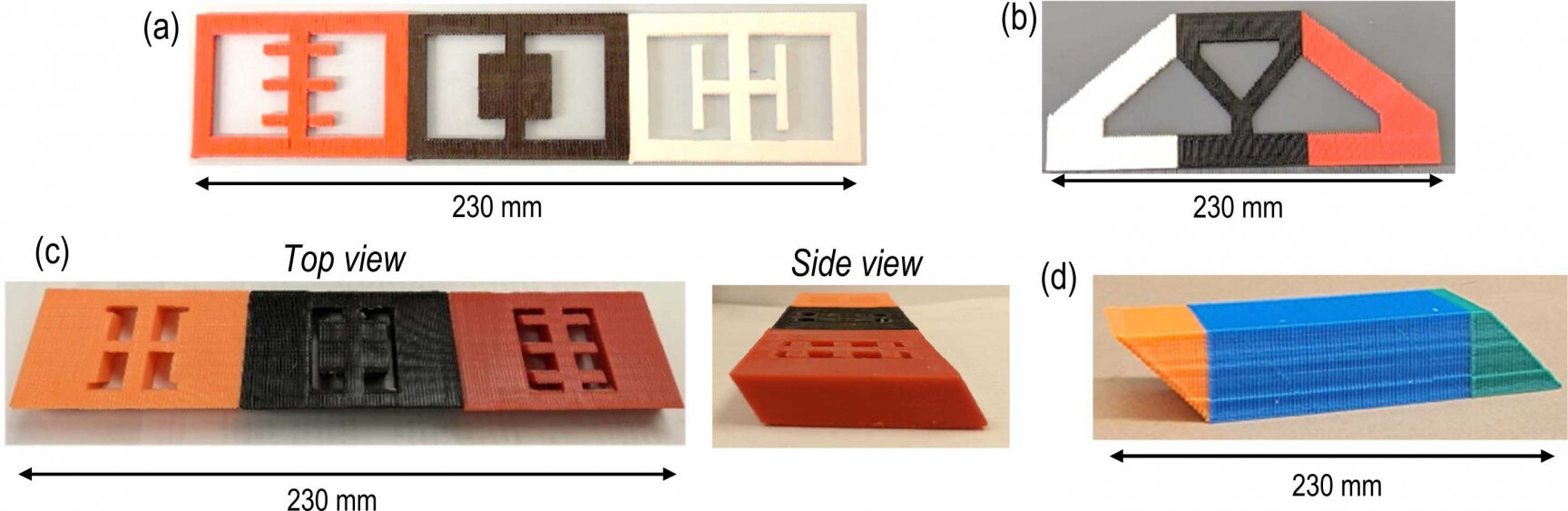

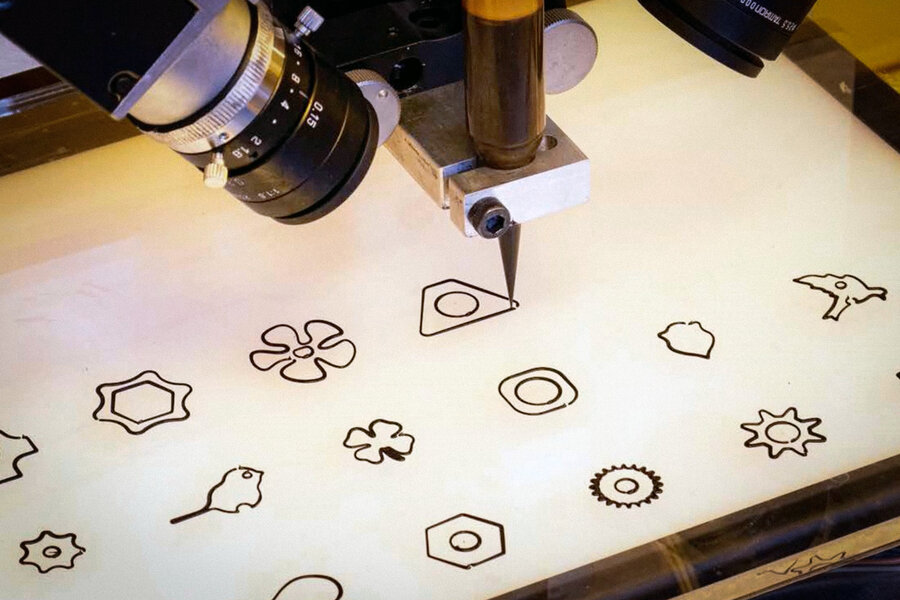

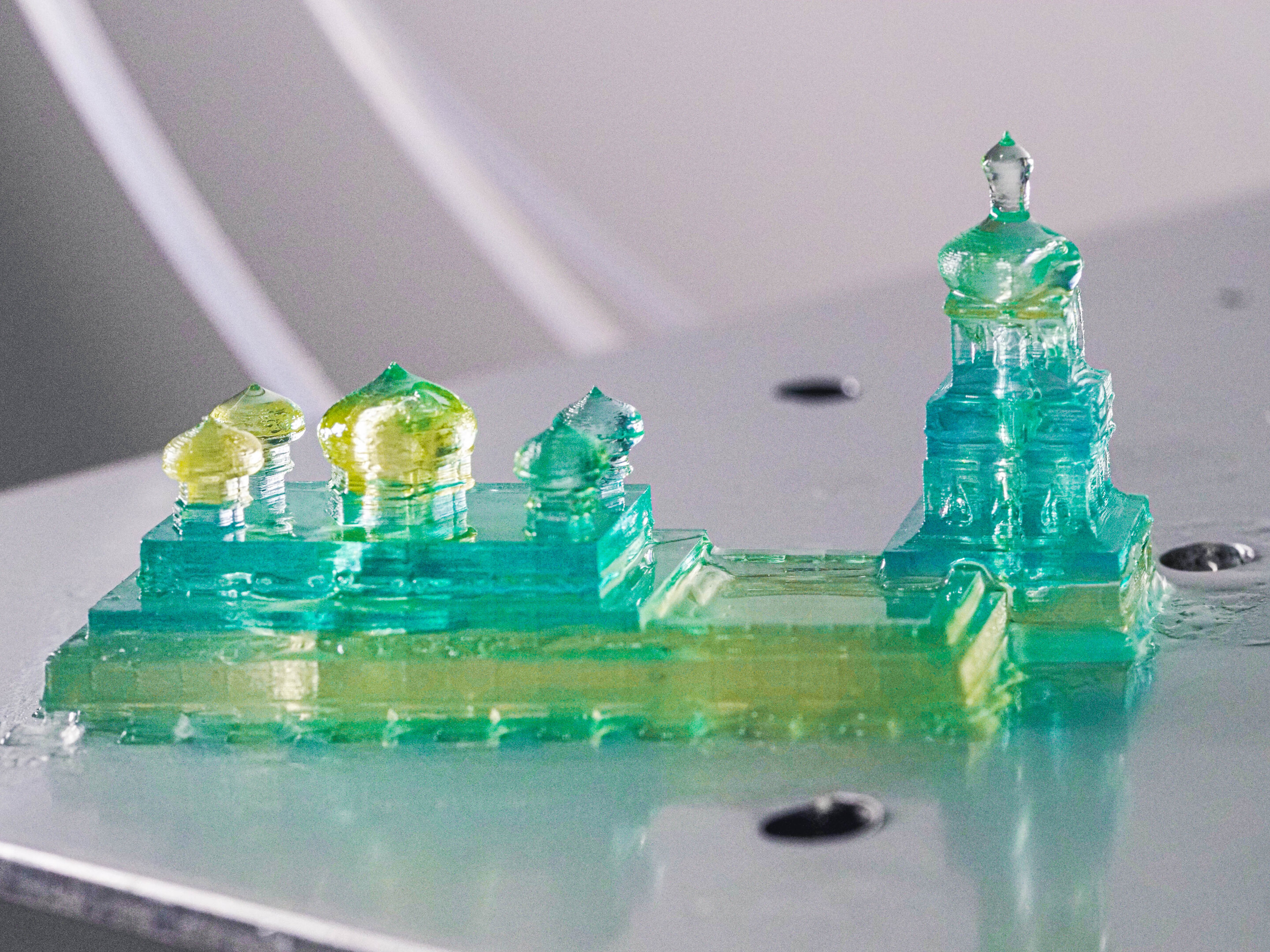

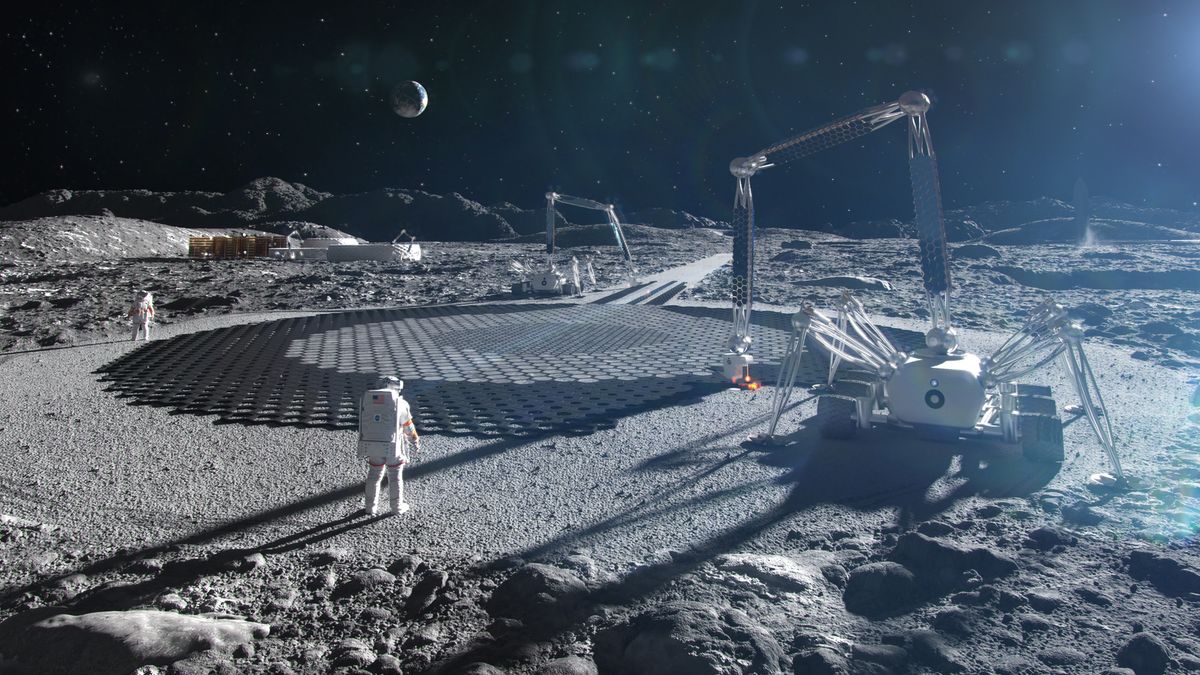

WSJ News Exclusive | 3-D Printed Houses Are Sprouting Near Austin as Demand for Homes Grows

Lennar is teaming with a Texas startup to create a community of 100 3-D printed homes near Austin, gearing up for what would be by far the biggest development of this type of housing in the U.S.