*sry for the reverse order:

Buffel part 2

The Buffel - Part 2

The Unimog 416.162- entry into service with the SADF and preparing for Buffel

Few would say the Unimog 416.162 was a pretty vehicle, but when it put on its "African bushjacket" the ugly duckling changed into a "meneer" that could take a real hammering in the wild and unforgiving country that is Africa.

When the SADF became interested in this vehicle, the Unimog 416 production line in Gagggenau was already in the process of being shut down in preparation for retooling for the new generation Unimog L130 and L170 of which some 15000 had been ordered at that time by the Bundeswehr.

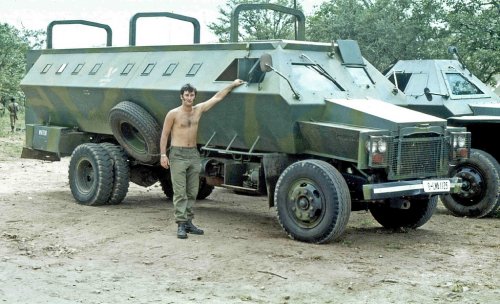

I have dealt elsewhere with all the drama and excitement surrounding the creation of the Unimog 416.162 during the runout of this product which was eventually supplied to the SADF from 1974 onwards and I include a picture of me with the first Unimog 416.162 off the production line for the first Armscor Unimog 416.162 contract at the time.

The first Unimog order was indeed an interesting one.

In typically Armscor fashion negotiations went round and round the mulberry bush - hurry, get us the latest prices and then we will place an order by the end of the week followed by silence and telephone calls not being returned then an urgent request for something else again and then silence and so it went on. In the meantime the Unimog people at Gaggenau I was working with were getting pretty "gatvol" of this "now it's on, now it's off" merry-go-round and told me so in no uncertain terms - the blunt message being "get your shit together and stop messing us around". As if I could tell Armscor what to do.

Then suddenly one day my phone rang and Armscor wanted to see me urgently. Now the deal was super urgent and Gaggenau must produce these vehicles "chop chop" because they were urgently needed as if Gaggenau had no other business to do and were just sitting around waiting to build Unimogs for SA. But that was Armscor.

Up to this time, all the while going around and around the mulberry bush, we had been asked to look at various options as well from part CKD assembly, then fully built up, then full CKD assembly and then CKD assembly with some local content and then back to fully built up and and and......

At that time plans were already underway within Armscor to build a new generation of trucks in South Africa and negotiations had started with interested parties to provide examples of their products for evaluation by the SADF before a down selection was made and negotiations entered into for local manufacture, but that is another story.

So we were not really surprized when Armscor called us in to finalize the first Unimog contract and advised us at these had to be supplied fully built (and delivered yesterday of course!) because it was unlikely anymore would be ordered with the locally manufactured products "due in the near future". So do not expect to supply anymore Unimogs after this contract was the message.

For the record, the first Unimog contract price was based on a rate of exchange of 1 Rand = DM 3.5635. DM is of course Deutschmark. As an aside, today the rate 1 Euro = 15.7 Rand. I know the Euro is not exactly what the DM was but that gives some indication of how the Rand collapsed over time as well.

When I contacted Gaggenau to advise them the contract had been signed and the vehicles were urgently needed they first thought I was joking because this had been going on for weeks and only when I said I would be visiting within a week to sort out all the details did they take it seriously.

In the Daimler Benz organisation from this point onwards Armscor /SADF was called customer PAUL and I in turn then codenamed all Unimog contracts as Project Paul, Pauline, Paula and Paulette to name but a few.

But I digress.

Credit must go to Gaggenau who pulled out all the stops to get the Unimog 416 production line back up and running to produce this order at very short notice and soon the fully built up Unimogs were rolling off the production line after which they had to be corrosion protected for their sea voyage before being shipped to South Africa in batches of 30 or more.

Photograph #1 was taken in 1974 at the Gaggenau factory when I inspected and signed off the first Unimog 416.162 with front mounted winch - 50 were ordered with front mounted winches

Gaggenau met its contracted delivery schedule to the unit and day and soon we were unloading Unimogs at the UCDD factory in East London, CDA, where they were prepped before delivery by road to Pretoria.

Whilst we were still in the process of delivering the first Unimog contract, surprize, surprize! Urgent call from Armscor. Can we supply some more Unimog 416.162 vehicles.

What about the advice that it was unlikely that there would be further orders after the first one and now we were also requested, once again at very short notice and with no prior warning, to build the rear bodies locally? No explanation, just a request to get a move on with the new contract (which once again was "top urgent") and which would almost definitely be the very last one this time. Ja, well no fine.

And this is where the Buffel story had its beginnings.

We requested quotations from local bodybuilders to build the rear platforms locally and finally settled on Messrs DogsBodies in East London which was owned and managed by Mike Stent at the time to build the rear bodies.

Mike was a "straight shooter" and a "go getter" and working with him and his "get things done" workshop manager, Don McKay, was a real pleasure. Nothing was too difficult if they could humanly have a go at it and Mike was also a big supporter of local manufacture which is why his company later played such an important when we developed the Buffel.

With South Africa under rapidly mounting pressure from overseas at the time, Armscor then also put pressure on us to manufacture other Unimog components locally such as battery boxes, air tanks, braking system parts, exhaust systems, steering components, radiators etc for small quantities with no prospect of further orders. Crazy stuff. This made planning and scheduling almost impossible and furthermore, Armscor failed to realize that to replace these items whilst quantities and/or timelines were unknown or uncertain and without going through the process of manufacturing local samples first for testing and approval before incorporation was very risky but we started doing it nevertheless so that we could not be accused of being unwilling to help.

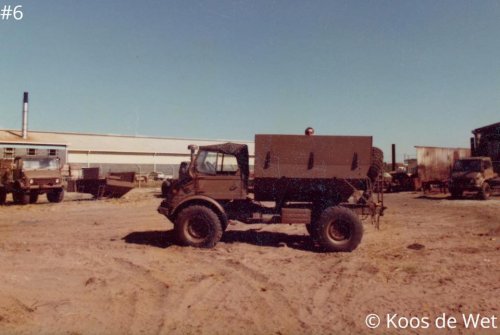

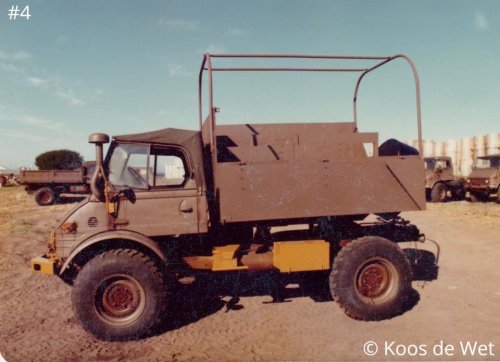

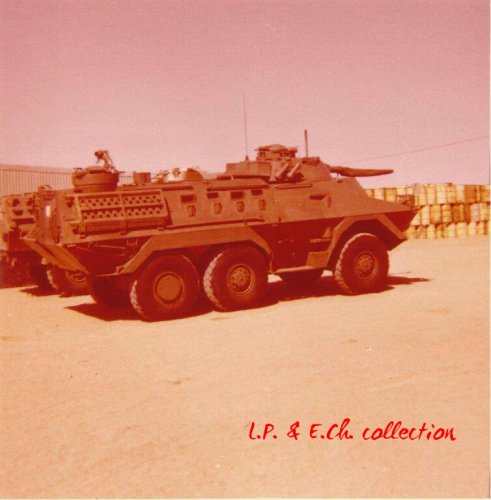

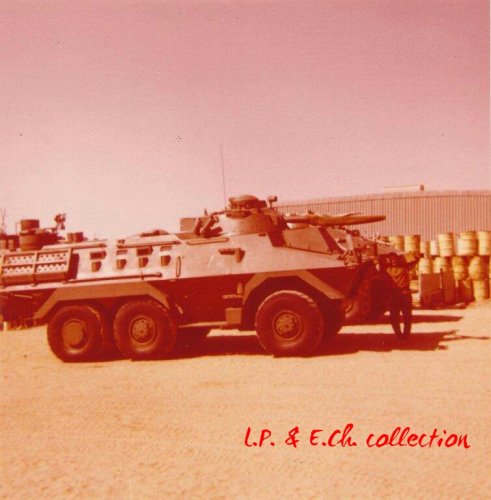

For us the logical thing to do was to pick the "low hanging fruit" first and soon Mike and his team had made battery boxes, spare wheel carriers, mirror holders and front bumpers which can be seen in photograph #2 where we used a 416.162 chassis on which we did our local content development to fit our original plywood concept Buffel body. The local parts are yellow in colour in this photograph.

With the order for 500 Unimogs being the "last" originally the final score was: 500 + 200 +396 +299 = 1395 Unimogs plus a few small orders by the time I left UCDD in 1980 when the Samils were getting into full production.

In summary, I negotiated and managed all the contracts for the supply of more than 90% of all Unimogs supplied to South Africa and when the final Unimog 416.162 was delivered to South Africa the Unimog 416 line was shut down permanently, some 8 years after the originally scheduled date and only spare parts were produced for this vehicle after that date and these mostly to order.

The Buffel development proper is covered in Part 3 which I am posting next.