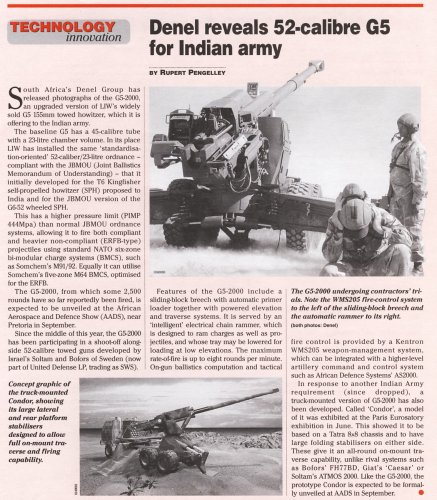

Denel Announces Latest G5 Towed Artillery Gun System

(Source: Denel Group; dated June 16, web-posted June 19, 2003)

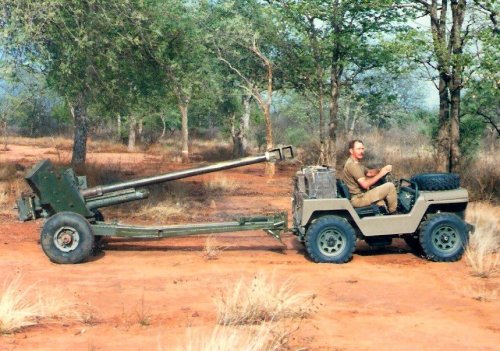

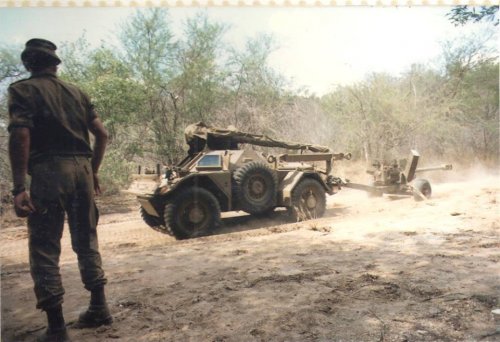

A substantially improved version of the renowned G5 155mm towed artillery gun system, designated G5-52, has just completed firing trials at the Alkantpan Test Range following development work at LIW, a division of South Africa's Denel Group.

In line with Denel's standard artillery gun nomenclature, this version is known as the G5-52, as the ballistic system is a JBMoU standard 52-calibre, whereas our truck mounted version is named the T5-52, explains Mr Louis Dirker, Group Executive Director, Denel Ordnance. Importantly, as with all Denel's artillery developments, we adhered to a systems approach in the development of the ballistic system, ensuring availability of a gun with a full range of projectiles and fuzes, and a bi-modular charge system which can all be fired safely at the full operating temperature range.

The major improvement to the G5 is a burst loader and a complete projectile handling system, comprising:

-- an electrically-driven chain rammer which loads both the projectile and the charge in the gun barrel;

-- a projectile magazine holding six projectiles in two layers; and

-- a small crane to transfer three projectiles at a time from a ground pile to the projectile magazine.

This latest development meets the requirements of the South African National Defence Force (SANDF) and other potential buyers for improved ergonomic gun designs.

One aspect taken into account in the design was the 47kg mass of a 155mm projectile, considered heavy for the average soldier to handle during the loading process. The new system requires no man-handling of projectiles. Only the charge, much lighter at 17kg, has to be placed manually on the loading tray, from where it is automatically pushed into the barrel chamber.

A unique feature of the system is that a firing mission can start with one round in the barrel, one on the loading tray, six in the magazine and three on the crane, says Louis Dirker. Therefore, a total of eleven rounds can be fired without any manipulation of ammunition - a world first for towed gun systems.

A firing rate of six rounds per minute is achievable with the top charge at all elevations. With the fully integrated command system and automatic laying system, MRSI (multiple round simultaneous impact) missions can be conducted with minimal operator assistance.

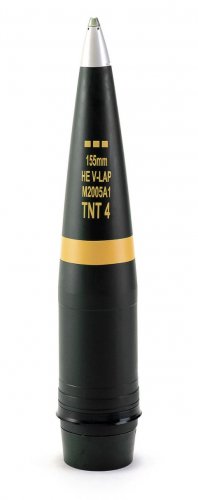

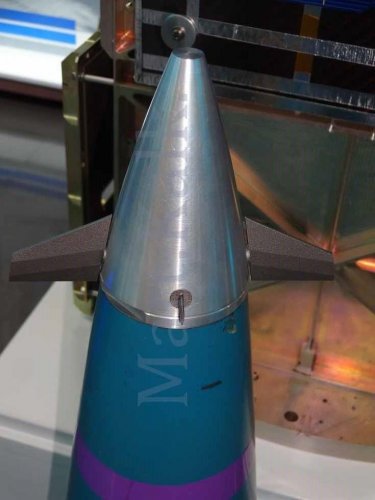

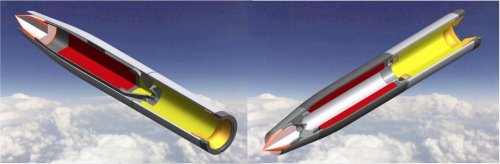

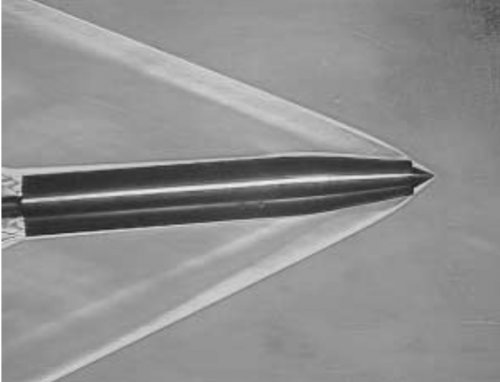

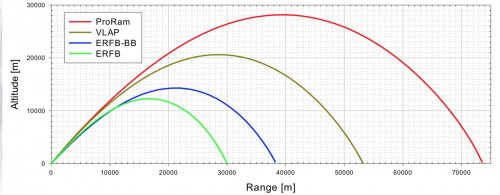

The G5-52 fires the Denel range of ERFB boat-tail, base-bleed and VLAP projectiles with the M90 bi-modular charge system at a top-charge muzzle velocity of 923m/s.

This gives the G5-52 a sea level range of 41,6km (using base bleed) and 55,3km with VLAP ammunition at 21°C. The operating pressure at 60°C is 430 MPa, providing a large margin of safety in the gun, which has been designed to withstand a pressure of 520 Mpa (with the G6-52L Losvoor derived barrel and breech mechanism).

The 52-calibre ballistic system is not very forgiving when it comes to mixing and matching of system elements, says Mr Org Ehlers, General Manager of LIW. Through its integrated system approach, Denel has ensured that it is the only supplier that can safely fire a 52-caliber artillery system without any restrictions.

The G5-52 complements Denel's lineup of 155mm high performance artillery gun systems, consisting of the G5 and G6 in 45-calibre, the G6-52 and -52L (long range Losvoor), the T6-52 autonomous turret, G5-52 and truck mounted T5-52.

Link