bring_it_on

I really should change my personal text

- Joined

- 4 July 2013

- Messages

- 3,679

- Reaction score

- 3,863

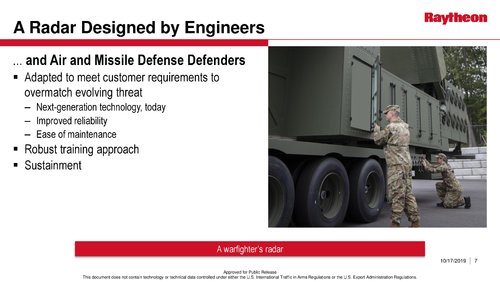

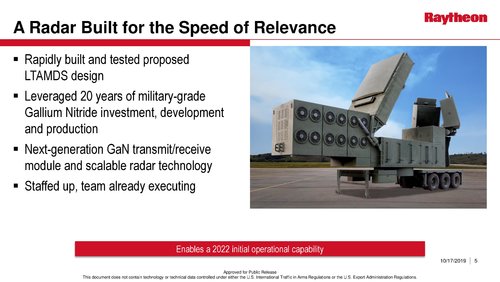

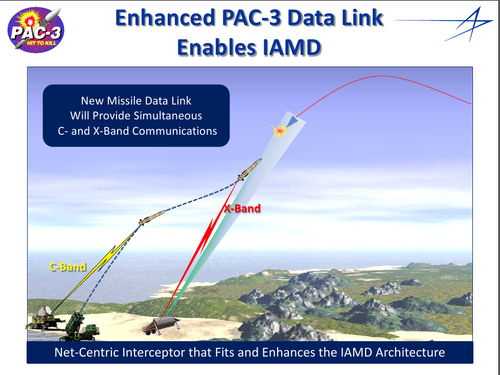

As per Raytheon is not a mock-up and an actual prototype in support of the program. The article posted earlier goes into how the stabilization mechanism is different (relevant portion quoted below). I would not call this a massive radar from a logistical or mobility perspective (relative to what it is replacing). Yes it is about 2.5 meters longer than the legacy radar but you get quite a bit in return for that. And the radar meets the Army's required mobility needs and utilizes the same movers and air-lift compared to the radar it is replacing. A large GaN AESA antenna on a high performance radar is going to consume a lot of power and is going to require a lot of cooling when it is in this frequency range. There are very limited options to avoid that. You can go for a more efficient lower frequency radar, reduce the volume search, range, and other performance requirements, or use a rotating radar to achieve 360 degree. The Army had made it clear that it was not willing to compromise on performance for the sake of 360 degree coverage so Raytheon needed to achieve both as the Congress inserted a 360-degree language in the NDAA and even though the Army did not specify a 360 degree sensor it was quite clear that they would want one that could at the very least grow to meet that requirement. One way they could have made it smaller is by placing the CEU on a separate mover like they do on the TPY-2 but that would have probably not met mobility or operational needs and would have increased the airlift requirement.

No it does not need to rotate - that is the entire point of developing a staring sensor. Raytheon has disclosed that the rear panels are designed to offer more than 2x the search range of the current Patriot radar which would be plenty of rear sector performance given the LTAMDS mission. They are sized to perform the full spectrum of PATRIOT's mission. There will also be other sensors operating as part of the PATRIOT battalion and within the broader IAMD fold covering other vectors and airspace. I did reach out to a Raytheon team member to see if the radar can slew and whether that capability will be carried over from the legacy sensor into the fielded LTAMDS sensors. Haven't heard back but I would be highly surprised if the final variant of their sensor doesn't offer that capability in some shape or form. There is some indication that the ability to slew is built into the design and may show up in the final delivered product..

The radar that Raytheon specifically designed for the Army uses next-generation gallium nitride technology and is 7 feet longer but 11 inches more narrow than the radar unit. But it no longer requires outrigger stabilizing legs. Rather, the system is held stable by jacks underneath, which means its takes up less space on the sides, according to Bob Kelley, Raytheon’s director of domestic integrated air and missile defense programs for business development and strategy.

If it rotated why would you need three arrays?

No it does not need to rotate - that is the entire point of developing a staring sensor. Raytheon has disclosed that the rear panels are designed to offer more than 2x the search range of the current Patriot radar which would be plenty of rear sector performance given the LTAMDS mission. They are sized to perform the full spectrum of PATRIOT's mission. There will also be other sensors operating as part of the PATRIOT battalion and within the broader IAMD fold covering other vectors and airspace. I did reach out to a Raytheon team member to see if the radar can slew and whether that capability will be carried over from the legacy sensor into the fielded LTAMDS sensors. Haven't heard back but I would be highly surprised if the final variant of their sensor doesn't offer that capability in some shape or form. There is some indication that the ability to slew is built into the design and may show up in the final delivered product..

Attachments

Last edited: