But those overhead cost wouldn't be reflected in the NAVSEA cost/ton metric. Those costs tend to show up in plan costs and ECO.Surprised the amphibs only 12% cheaper per ton than the CVNs built at NNS with its high overheads driven by nuclear costs, tends to confirm the impression that both BIW and Ingalls yards expensive,

Of interest In the Navy briefing on Bonhomme Richard in December prior to the scrapping quoted $4.1 billion as the replacement cost, which will include the shipyard overheads. At at first look makes it look very expensive ship if built in US, compared to the QNLZ, a 60% larger ship cost the same, would inflation account for the difference?

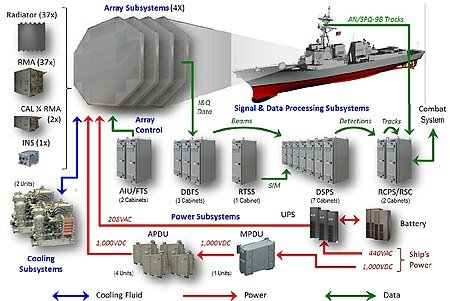

CBO base estimates on lightweight displacement cost per ton, using actuals of current surface combatants, Burkes and LCS, costs driven partly by density, Constellation is a lower density ship than a Burke who have over the years been burdened with more equipment eg with Flight III have had to resort to relocating an accommodation block on the rear weapons deck so as to make more room for the additional hardware needed below weapons deck to support the new SPY-6 radar.The believed drivers for non-CV/amphib surface combatant costs are outfit density and power density; Constellation is bad on both counts.the CBO and CRS both expressed incredulity at the Fincantieri costs for the new Constellation frigates

So some skepticism there is warranted. But that has nothing to do with CVs.

CBO estimate 40% above Fincantieri/Navy Constellation contract price using their metrics, when challenged CBO claim their justification for the 40% uplift was the addition of 300t of steel to the FREMM for Constellation which would make it more complicated to build, but 40%? The 2015 Italian contract for 9th and 10th FREMMs was 764 million euros ~$930 million, ~$470 milion each, Navy contract for Constellation $870 million each if all ten contracted.

Their cost overruns on LCS notwithstanding apparently.Fincantieri contested the CBO and CRS figures, it has a long history in building cruise ships on time and cost

Freedom class prime contractor was Lockheed and the naval architects Gibbs and Cox, with Constellation Fincantieri are both the prime contractor and naval architect for ship giving them control.

I don't see anything preventing the automation of HSLA welding beyond the fixed-costs of automation.If using the newer HSLA steel which saying is a very labor intensive to weld and if not be suitable for robotic welding would not it be a better trade off to use thicker commercial weldable steels eg DH36/EH36 controlled rolled and normalized, heat treated to stress relive the steel to give necessary toughness as used in the UK carriers) understand Far Eastern and European shipyards now able to weld hull with robotic production lines and even mention of spider automatic robots for assembly and welding.

IIRC, toughness scales at the square root of thickness so achieving the much higher toughness of HSLA requires

a much greater than linear amount of material. Not sure that really saves any money.

Of interest found some comments on Google by Ray D

HSLA is comparatively much worse as an armor material than the entire HY-series, possessing a relatively low hardness, lower UTS, and inability to be produced in thickness - in addition to costing more than HY-80 to begin with. Practically the only advantage of HSLA is its weldability.

The HY series of USN metal standards actually derives their names from their respective Yield Strengths. HY-80 steel is High Yield 80 ksi (thousand lbs/in^2) Steel, whereas HY-100 steel is High Yield 100 ksi Steel, meaning HY-100 has a 25% higher yield strength. This is actually slightly misleading when it comes to a material's protective value. Yield Strength is the capability of a material to withstand compressive force and return to its original form, for example the strength of a wall to hold up a roof. Essentially it's structural strength.

When considering for armor steel, however, the values you have to pay attention to are Ultimate Tensile Strength and Hardness. Ultimate Tensile Strength (UTS) is, simply put, the amount of force a given metal can resist before it is torn apart, ether by a vice or a projectile slamming into it. Hardness is, for most purposes, an obvious effect and I won't spent the character limit breaking it down. For HY-80/100, these values are a lot closer than their Yield Strengths.

HY-80 has a Rockwell Hardness of 20 and a UTS of 100ksi.

HY-100 has a Rockwell Hardness of 21 and a UTS of 115ksi.

A roughly 13% difference.

So, yes, HY-100 can easily be a significantly better armor material than HY-80, and the nearly Titanium-like HY-130 doing even better... when employed in significant enough thicknesses for that to make a difference. When you are dealing with thinner sheets, such as hull plating, it is generally more economical to design the ship around using a slightly thicker sheet of HY-80 than HY-100 unless the yield strength of the metal is going to come into play, such as with Submarines - and even then, we used to build Submarines out of HY-80. You end up with a slightly heavier ship, a few tons, but it presents a much more economical building plan.