- Joined

- 25 June 2009

- Messages

- 14,754

- Reaction score

- 6,155

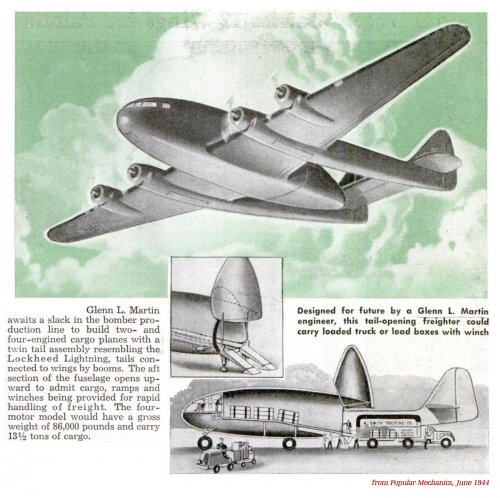

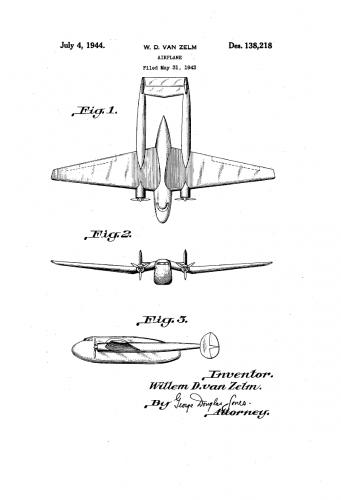

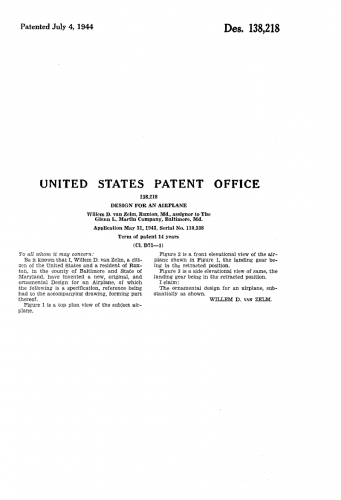

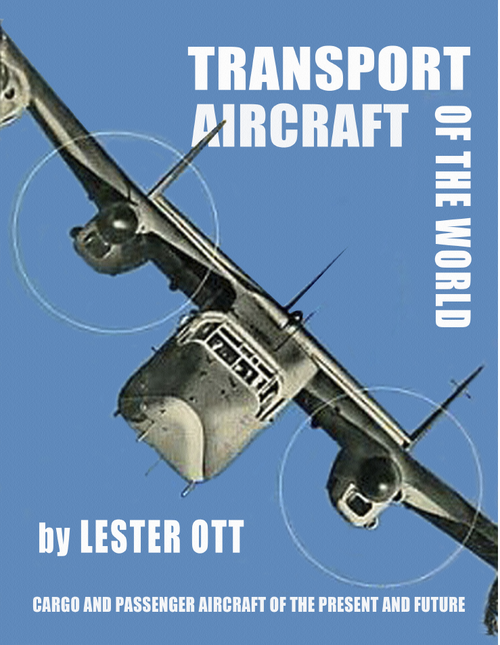

A GLENN MARTIN CARGO-CARRIER

published in Aeronautics, July 1948

published in Aeronautics, July 1948

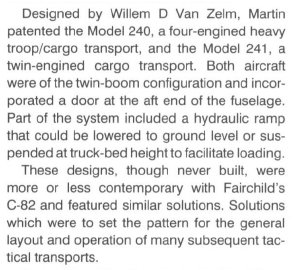

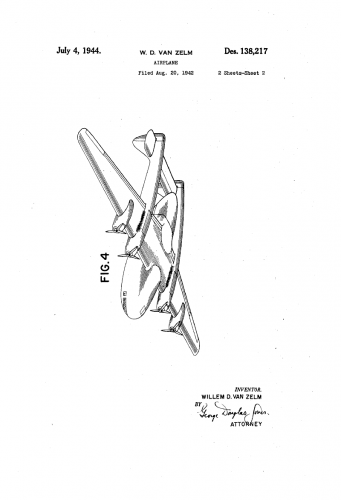

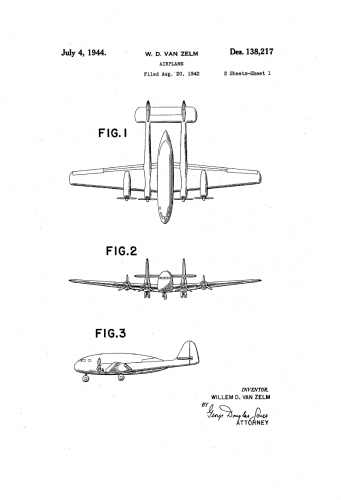

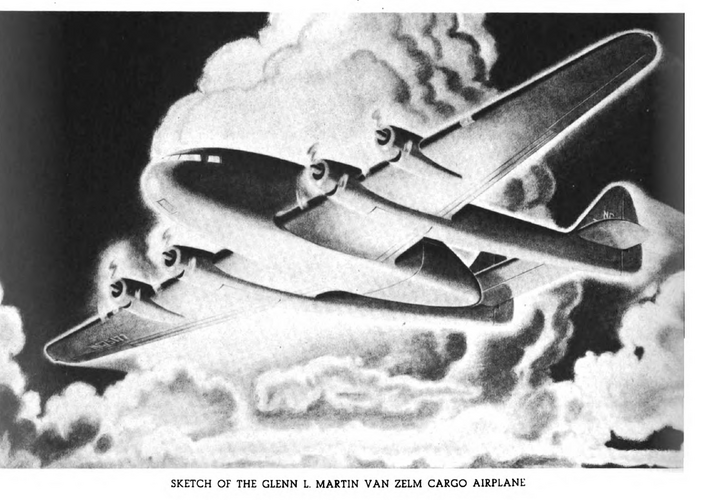

A heavy cargo-carrying aircraft, which is a project of the Glenn L. Martin Company, of Baltimore, U.S.A., has been patented in this country. It is similar in its main form of construction to some other freight carriers. For instance the airframe is made up of a main cargo-carrying body which is arranged between two tail booms attached to the wings. Freight is loaded and unloaded through a door built in the rear of the body, and a tricycle undercarriage is employed to facilitate these operations.

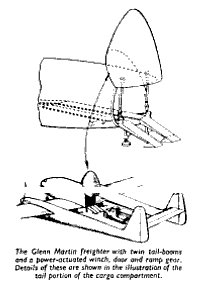

The Miles Aerovan and the Fairchild freighter have these features also. The Glenn Martin design is somewhat more elaborate, however. The door, for example, is servo-actuated and is connected with a ramp and jack mechanism, the whole working together. The servo motors can be either hydraulic or electric and they are remotely controlled from the pilot's cabin. In use, the operator stands and looks through a window to the rear of the aircraft and on his setting the motors in action, the door is swung upwards. Simultaneously, ramps are lowered. These are constructed with legs or jacks, the feet of which can be adjusted to extend to the ground surface and so reinforce the ramps when loads are being moved into or out of the cargo compartment.

The cargo is pulled into the aircraft by means of a power-operated winch and cable which travels beneath the flooring, where it is directed by guide rollers. Due to its position beneath the flooring, this cable is adapted to reduce force that might be set up and unbalance the aircraft during the loading and unloading operations. The guide rollers can be employed also to pass the cable around the freight already installed in the compartment.

The description of this machine provided in the Patent Specification contains a reference to the possibility of employing a compound winch to operate more than one cable. Freight can be quickly and easily transferred from a lorry to the aircraft by this loading apparatus. The lorry is backed to the rear of the machine, and the servo motors are thrown into actuation. The door then opens and at the same time the ramps emerge and swing downwards. After the jacks have been adjusted, the tailboard of the lorry is placed beneath the ramps, and as the cargo is moved aboard, the weight is not transferred to the body portion until it has passed over the hinges of the ramps. In this way the aircraft is kept in balance while the loading is being carried out.

This design was worked out by the Glenn Martin Company during the war and was patented in the United States in August, 1942. It was intended that it should be incorporated in transport aircraft used for carrying field guns and tanks. A British Patent was applied for in 1943 and the complete specification was accepted in March, 1948.