You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lockheed-Georgia Spanloader Aircraft studies

- Thread starter Dronte

- Start date

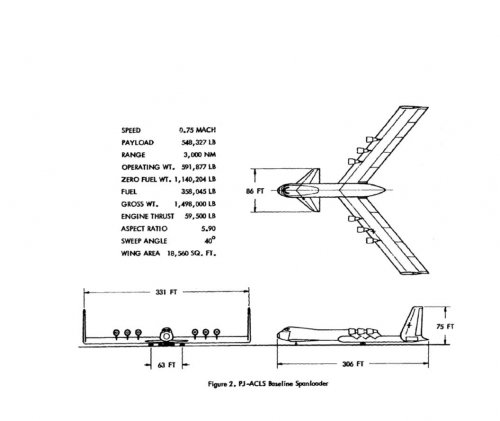

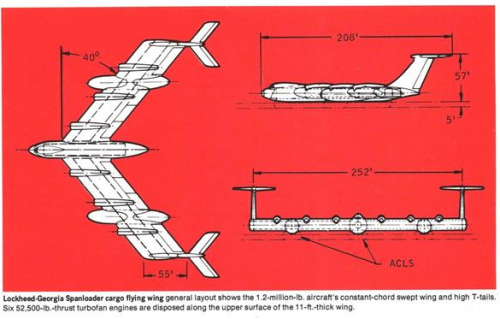

Peripheral Jet Air Cushion Landing System Spanloader Aircraft. Volume I by JW Moore et al., Lockheed-Georgia Co Marietta, December 1979

Abstract:

Peripheral Jet Air Cushion Landing System Spanloader Aircraft. Volume II by JW Moore et al., Lockheed-Georgia Co Marietta, December 1979

http://handle.dtic.mil/100.2/ADA085117

Abstract:

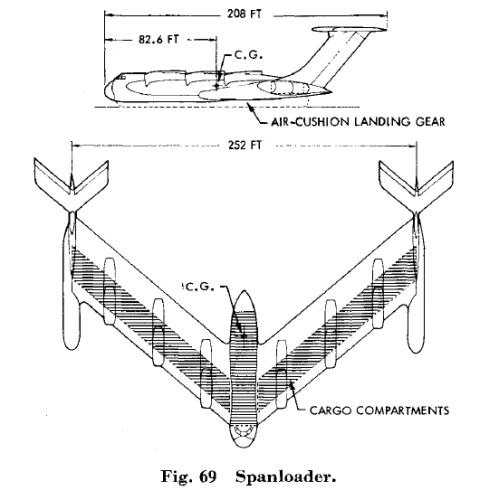

http://handle.dtic.mil/100.2/ADA085203Inherent in the design optimization of wing span-distributed load (spanloader) aircraft is the lack of ground operational down bending load reaction capability of the wing structure. It is necessary to provide a means to react these down bending loads if the wing structural weight is minimized. Recent studies have provided wide tread landing gears as a means to react these down bending loads, limiting the operational capability of the aircraft where the tread width exceeds most existing airport taxiway or runway widths. This study examines the feasibility of replacing the wide tread gear with a peripheral jet air cushion landing system (PJ-ACLS) in combination with a minimum tread (75 feet) width gear. The PJ-ACLS is located adjacent to the wing tip and is used primarily as wing down bending load reaction device. The minimum tread width gear is retained to simplify takeoff and landing procedures and to reduce the magnitude of the lift required from the PJ-ACLS.

Peripheral Jet Air Cushion Landing System Spanloader Aircraft. Volume II by JW Moore et al., Lockheed-Georgia Co Marietta, December 1979

http://handle.dtic.mil/100.2/ADA085117

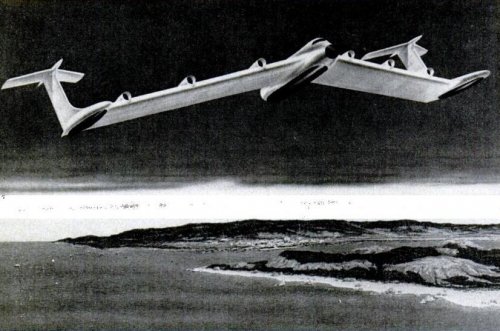

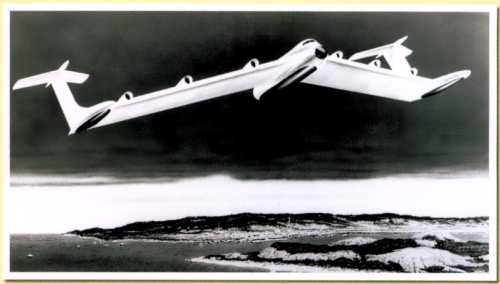

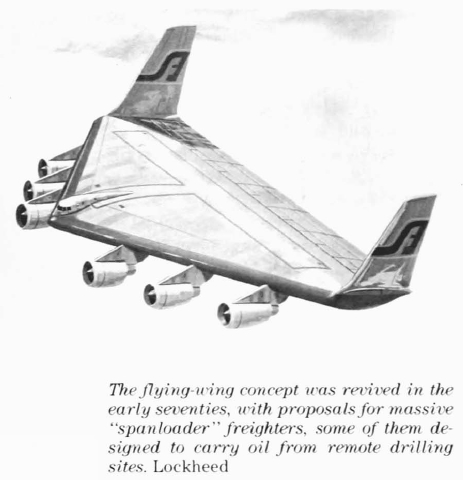

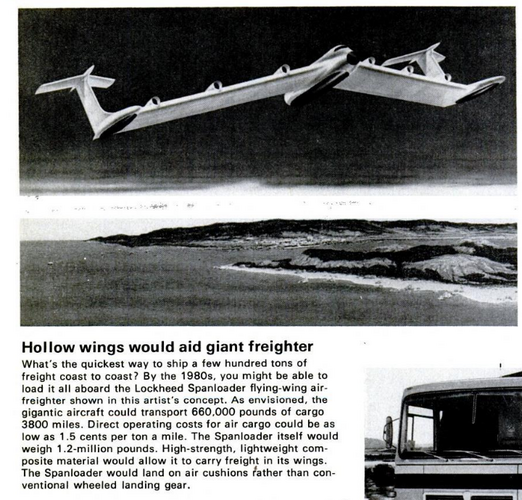

Artist's impression of Lockheed Spanloader flying wing air freighter design circa 1974.

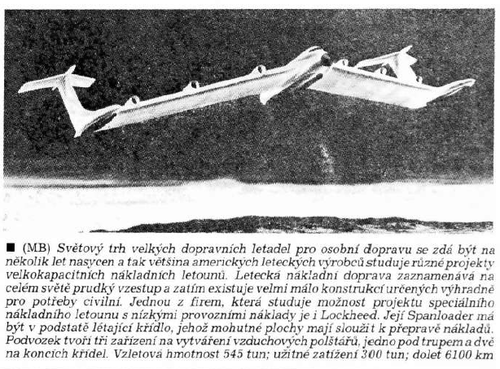

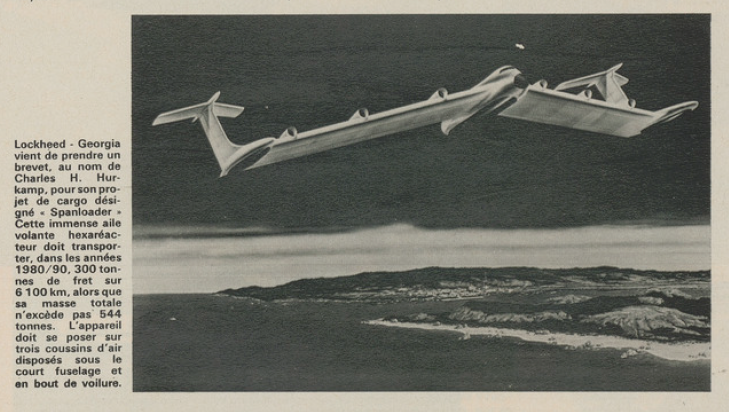

As envisioned, the gigantic aircraft could transport 660,000 tons of cargo 3,800 miles. Direct operating costs for air cargo could be as low as 1.5 cents per ton per mile in 1974 US Dollars. The Spanloader itself would weigh 1.2 million pounds. High-strength light weight composite material would allow it to carry freight in its wings. The Spanloader would land on air cushions rather than a conventional landing gear.

Source:

(1) "Hollow Wings Would Aid Giant Freighter" Popular Science March 1974

(2) Spanish science magazine Conocer (1992 I think). It could be a translation from French Magazine Science et vie (via pometablava)

As envisioned, the gigantic aircraft could transport 660,000 tons of cargo 3,800 miles. Direct operating costs for air cargo could be as low as 1.5 cents per ton per mile in 1974 US Dollars. The Spanloader itself would weigh 1.2 million pounds. High-strength light weight composite material would allow it to carry freight in its wings. The Spanloader would land on air cushions rather than a conventional landing gear.

Source:

(1) "Hollow Wings Would Aid Giant Freighter" Popular Science March 1974

(2) Spanish science magazine Conocer (1992 I think). It could be a translation from French Magazine Science et vie (via pometablava)

Attachments

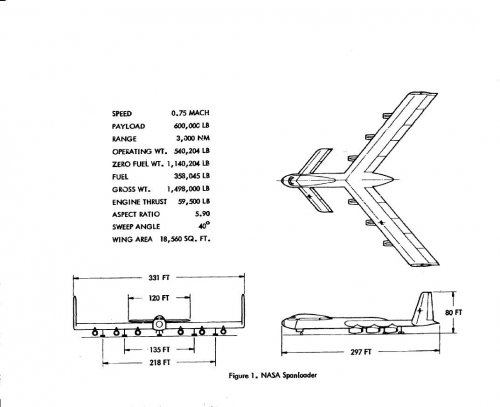

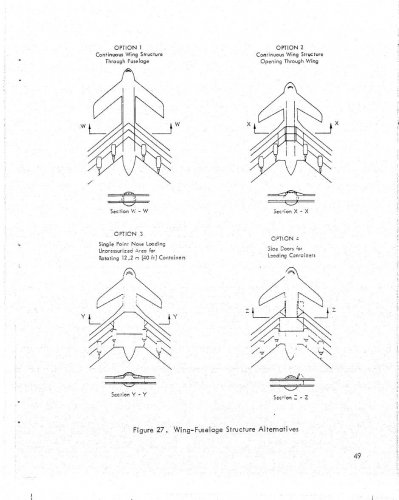

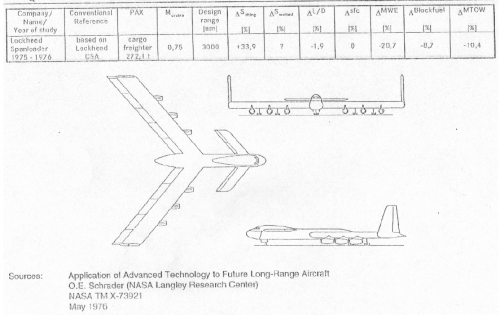

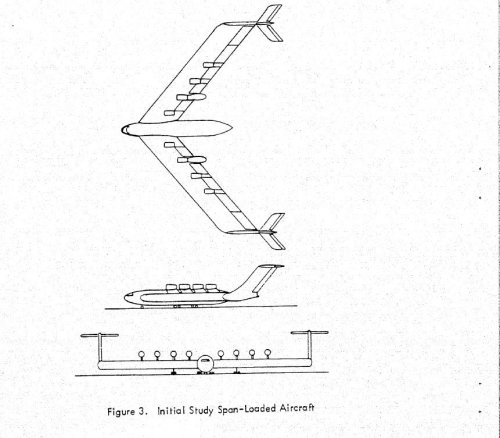

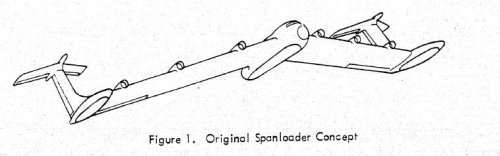

Lockheed-Georgia Span-Distributed Loading Aircraft (spanloader) concepts circa 1976 as part of the Span-Distributed

Loading Aircraft Studies commissioned by the NASA Langley Research Center.

Source:

Johnston, W. M.; Muehlbauer, J. C.; et al. Technical and Economic Assessment of Span-Distributed Loading Cargo Aircraft Concepts , Lockheed-Georgia Company, August 1976.

Abstract:

URL:

http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19760026098_1976026098.pdf

Loading Aircraft Studies commissioned by the NASA Langley Research Center.

Source:

Johnston, W. M.; Muehlbauer, J. C.; et al. Technical and Economic Assessment of Span-Distributed Loading Cargo Aircraft Concepts , Lockheed-Georgia Company, August 1976.

Abstract:

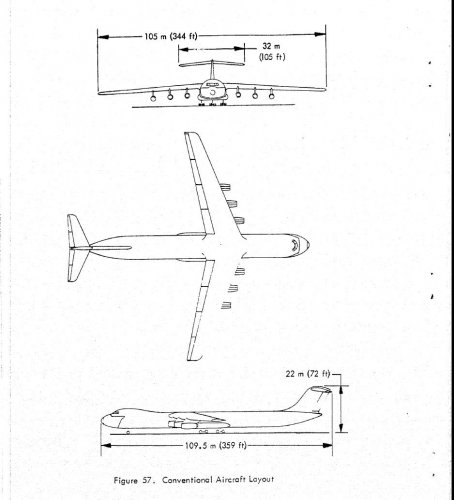

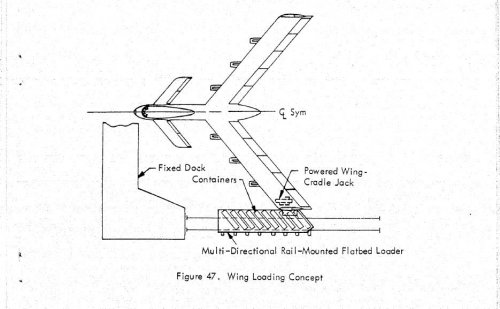

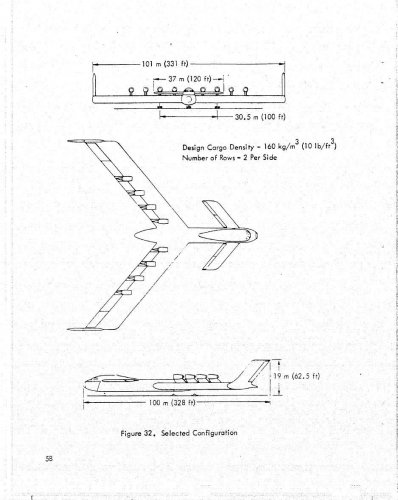

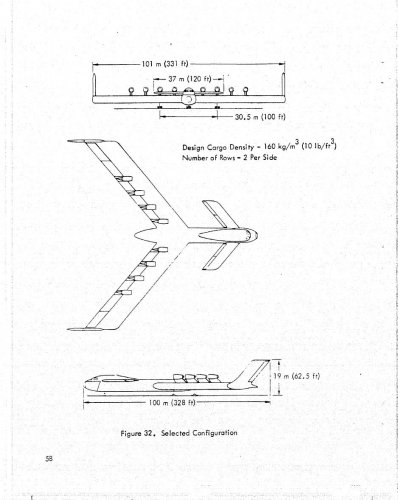

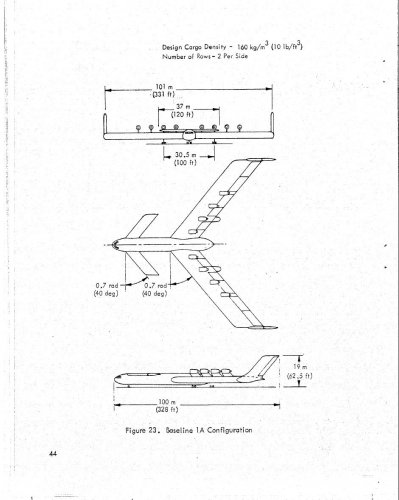

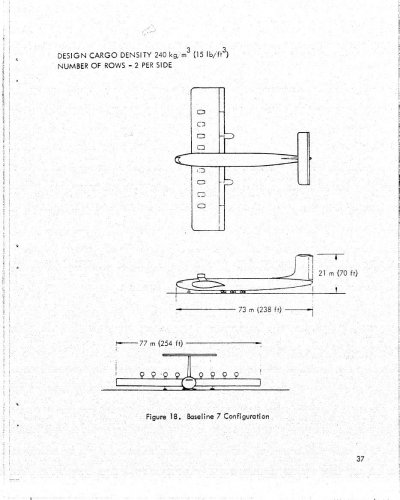

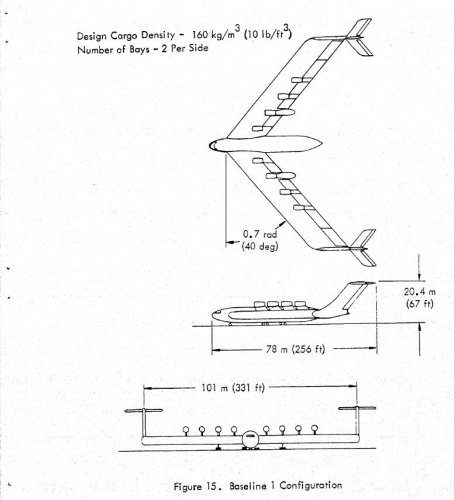

Studies were conducted to assess the technical feasibility and to evaluate the economics of a span-distributed loading aircraft relative to a conventional aircraft. A 700,000 kg (1,540,000-lb) aircraft with a cruise Mach number of 0.75 was found to be optimum for the specified mission parameters of a 272,155-kg (600,000-Ib) payload, a 5560-km (3000-n .mi.) range, and an annual productivity of 113 billion revenue-ton km (67 billion revenue-ton n. mi .). The optimum 1990 technology level span loader aircraft exhibited the minimum 15-year life-cycle costs, direct operating costs, and fuel consumption of all candidate versions.

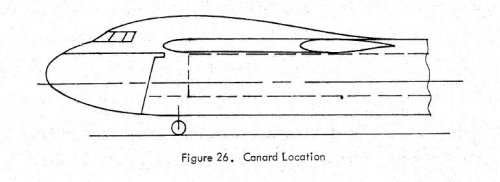

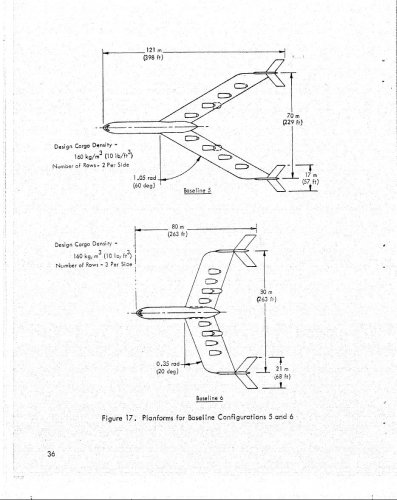

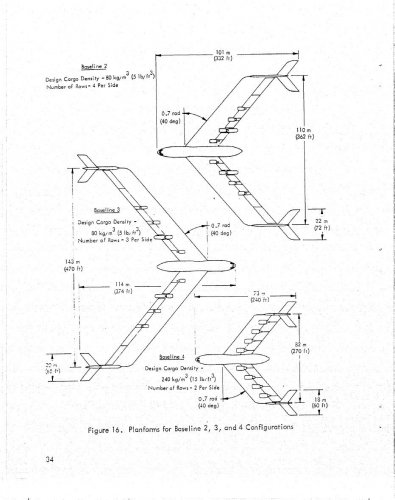

Parametric variations of wing sweep angler thickness ratio, rows of cargo, and cargo density were investigated. The optimum aircraft had two parallel rows of 2.44 x 2.44-m (8 x 8-ft) containerized cargo with a density of 160 kg/cu m (10 Ib/cu ft) carried throughout the entire 101-m (331-ft) span of the constant chord, 22-percent thick, supercritical wing. Additional containers or outsized equipment were carried in the 24.4-m (80-ft) long fuselage compartment preceding the wing. Six 284,000-N (64,000-Ib) thrust engines were mounted beneath the 0.7-rad (40-deg) swept wing. Flight control was provided by a 36.6-m (120-ft) span canard surface mounted atop

the forward fuselage, by rudders on the wingtip verticals and by outboard wing flaperons.

Benefits of the spanloaded aircraft relative to a conventional aircraft with identical mission capability are: 11.7-percent lower direct operating and 15-year life-cycle costs, 8.2-percent less fuel consumption, 20.8-percent lighter operating weight, and a 10.4 percent smaller gross weight. Cargo loading and the 66.5-m (218-ft) main landing gear tread will pose potential airport compatibility problems.

URL:

http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19760026098_1976026098.pdf

Attachments

-

spanloader08.jpg28.8 KB · Views: 120

spanloader08.jpg28.8 KB · Views: 120 -

Spanloader07.jpg130.8 KB · Views: 117

Spanloader07.jpg130.8 KB · Views: 117 -

Spanloader06.JPG167.1 KB · Views: 113

Spanloader06.JPG167.1 KB · Views: 113 -

Spanloader05.JPG170.3 KB · Views: 116

Spanloader05.JPG170.3 KB · Views: 116 -

Spanloader04.JPG135.7 KB · Views: 115

Spanloader04.JPG135.7 KB · Views: 115 -

Spanloader03.jpg78.4 KB · Views: 121

Spanloader03.jpg78.4 KB · Views: 121 -

Spanloader02.JPG92.8 KB · Views: 121

Spanloader02.JPG92.8 KB · Views: 121 -

Spanloader01.JPG32.1 KB · Views: 220

Spanloader01.JPG32.1 KB · Views: 220

Continued Lockheed-Georgia Span-Distributed Loading Aircraft (spanloader) concepts circa 1976 as part of the Span-Distributed Loading Aircraft Studies commissioned by the NASA Langley Research Center.

Source:

Johnston, W. M.; Muehlbauer, J. C.; et al. Technical and Economic Assessment of Span-Distributed Loading Cargo Aircraft Concepts , Lockheed-Georgia Company, August 1976.

Foreword:

URL:

As above

Source:

Johnston, W. M.; Muehlbauer, J. C.; et al. Technical and Economic Assessment of Span-Distributed Loading Cargo Aircraft Concepts , Lockheed-Georgia Company, August 1976.

Foreword:

The Lockheed-Georgia Company conducted a technical and economic assessment of span-distributed loading cargo aircraft concepts as part of its Independent Development Program. The approach, guidelines, and requirements outlined in NASA Request for Proposal 1-16-5603 provided the basis for the general plan followed in the Lockheed study. Several minor changes were made to the suggested guidelines, and some additional study

tasks were undertaken.

Monthly reports were submitted to Allen H. Whitehead, Jr., NASA's Span-Distributed Loading Aircraft Studies coordinator, to keep him informed of the latest progress on the Lockheed study. Several conferences, including mid-term and final presentations at the NASA-Langley facility on 23 October 1975 end 5 February 1976, respectively, were held to assure compatibility with the NASA efforts. Toward the end of the study, Lockheed and NASA agreed to make the results available in a NASA report to the general public • Funding to underwrite part of the cost of this publication was provided through Contract NAS 1-14383.

William M. Johnston" the Study Manager, and his Deputy, John C. Muehlbauer, were responsible for the overall direction of this study which was performed as part of a continuing preliminary design investigation of new aircraft concepts by the Transport Design Department - Roy H. Lange, Manager. Roy R. Eudaily coordinated the overall structures effort; specific responsibilities were as follows: Michael C. Campion - Loads, Charles M. Jenness - Flutter, Lewis B. Lineberger - Stress, and R. Earnest Stephens -Weights. Ben T. Farmer fulfilled the design requirements, Sterling G. Thompson performed the economic analysis, and John F. Honrath directed the aerodynamic performance and parametric activities. Other contributors to this study included: S. R. Anthony, J. A. Bennett, D. N. Byrne, B. N. Crenshaw, H. V. Davis, Jr., R. S. Ferrill, O. M. Hayes, J. G. Hewell, Jr., J. D. Sowers, V. L. Turner, and F. M. Wilson, Jr.

URL:

As above

Attachments

- Joined

- 25 June 2009

- Messages

- 14,749

- Reaction score

- 6,112

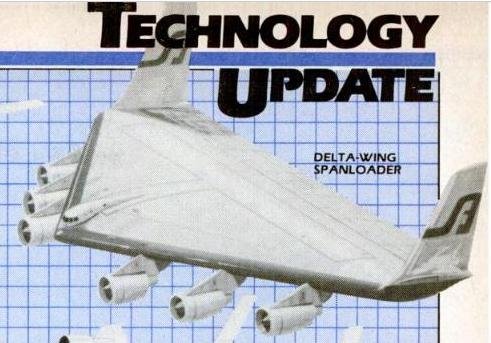

More on Lockheed Spanloader designs (a few repetitions here and there... : Hope some Lockheed buff can sort this all out):

Hope some Lockheed buff can sort this all out):

- Re: Lockheed 1979 NuCMCA (Nuclear-powered Cruise Missile Carrier Aircraft)

- Re: Various Airbus designs

- Lockheed-Georgia 1985 Future Cargo Aircraft studies

- Re: Various Lockheed civilian projects

- Lockheed LFC

- Lockheed Peripheral Jet Air Cushion Landing System Spanloader Aircraft

Attachments

Last edited by a moderator:

- Joined

- 3 June 2006

- Messages

- 3,094

- Reaction score

- 3,951

- Joined

- 26 May 2006

- Messages

- 34,869

- Reaction score

- 15,733

Hi,

here is a Lockheed Spanloader aircraft with air-cushion as a landing gear.

here is a Lockheed Spanloader aircraft with air-cushion as a landing gear.

Attachments

With AN-225 gone...you don't need me to say the rest. The size of the flaps needed and the unrelated French spaceplane design made me question thermal insulation. No this big plane was to use hydrogen yes? Maybe let it slough off and keep composite flaps away, instead of gluing foam or tiles. We hose planes down but outside fairings or stages themselves....I'm just wondering if there could be an air-space connection.

- Joined

- 27 December 2005

- Messages

- 17,741

- Reaction score

- 26,321

Updated patent links in post #9 above and added patent PDFs in case they break again.

- Joined

- 26 May 2006

- Messages

- 34,869

- Reaction score

- 15,733

(1) "Hollow Wings Would Aid Giant Freighter" Popular Science March 1974

With text.

Attachments

Similar threads

-

Lockheed-Georgia 1985 Future Cargo Aircraft studies

- Started by flateric

- Replies: 7

-

Lockheed LG-603 Advanced Technology Airlifter ATA Studies

- Started by boxkite

- Replies: 16

-

Lockheed-Georgia Omega "Sternwheeler" cargo aircraft

- Started by Triton

- Replies: 12

-

Lockheed of the Late '60s 5 - Model unidentified 1

- Started by Skybolt

- Replies: 4

-

Advanced Medium STOL Transport (AMST) and its predecessors

- Started by Pioneer

- Replies: 229