blackkite

Don't laugh, don't cry, don't even curse, but.....

- Joined

- 31 May 2007

- Messages

- 8,298

- Reaction score

- 5,914

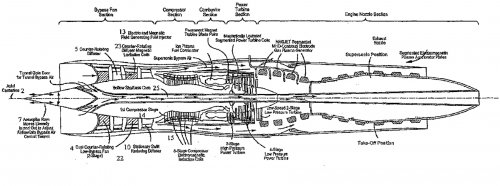

Hi! HyperMach SonicStar engine.

http://patentimages.storage.googleapis.com/US20110138765A1/US20110138765A1-20110616-D00000.png

http://hypermach.com/?page_id=66

The SonicBlue vision is the development of revolutionary engine design to fundamentally change the way aero gas-turbine engines operate in order to significantly improve the performance of aircraft systems.

a.Hybrid engine technology developed to offer a highly efficient, supersonic, variable bypass fan ratio engine design.

b.The engine operates electrically by generating a large amount of on-board electric power through its superconducting electric turbine ring generator system.

c.Engine produces sufficient power to operate the multi-stage counter rotating, superconducting, dual ring motor electric bypass fans and superconducting electric ring motor axial compressor, power generation and thrust comes from 5-stage superconducting axial turbine.

d.The 54,700 thrust class S-MAGJET engine (two engines) described is optimized to fly the HyperMach SonicStar aircraft at 62,000 ft, at a specific fuel consumption below 1.05 at Mach 3.3, this performance will be unprecedented and will welcome in a new era of the future of aerospace transport.

e.Electrical generation is provided by superconducting ring generators that are powered by the high velocity exhaust thrust from the combustor section of the engine.

f.The bypass fan is a twin fan system in which one fan counter rotates with the other fan, which reduces aerodynamic swirl and drag.

g.The bypass fan configuration is not constrained by a drive shaft, heavy gears and complex gear boxes, nor complex lubrication systems and it can be run at an optimal rotational speed so as to maximize its efficiency at any aircraft velocity, or altitude.

h.The bypass fans running independently from the compressor can be run at much slower speeds than the compressor, this means a more efficient RPM for the fan blade design of the S-MAGJET, a low bypass fan supersonic engine design.

i.Lower operating RPM speeds afford the use of wider blades, raising aerodynamic efficiency and thrust per horsepower, making the engine architecture greatly more efficient than the current art of engine designs.

j.Light weight superconducting ring motors with integrated cooling for the compressor do not require a drive shaft, nor the bypass fans or the superconducting ring generators of the power turbine, a “hollow-core shaft-less” tunnel is left in the center of the hybrid electric turbine which now carries additional bypass air.

k.Bypass air as the major component of thrust, rather than the hot exhaust from the power turbine being utilized as thrust is a more efficient method of producing thrust for propulsion in turbines.

l.Supersonic-Magnetic Advanced Generation Jet Electric Turbine (S-MAGJET), the majority of electric power produced off the power turbine via the superconducting ring generators is directed forward through a proprietary electric power management system to run the electric bypass fans and the electric compressor. This electrical independence of the bypass fan from the multi-stage axial compressor raises overall efficiency of the engine by 70% alone.

http://patentimages.storage.googleapis.com/US20110138765A1/US20110138765A1-20110616-D00000.png

http://hypermach.com/?page_id=66

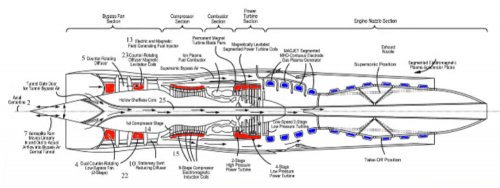

The SonicBlue vision is the development of revolutionary engine design to fundamentally change the way aero gas-turbine engines operate in order to significantly improve the performance of aircraft systems.

a.Hybrid engine technology developed to offer a highly efficient, supersonic, variable bypass fan ratio engine design.

b.The engine operates electrically by generating a large amount of on-board electric power through its superconducting electric turbine ring generator system.

c.Engine produces sufficient power to operate the multi-stage counter rotating, superconducting, dual ring motor electric bypass fans and superconducting electric ring motor axial compressor, power generation and thrust comes from 5-stage superconducting axial turbine.

d.The 54,700 thrust class S-MAGJET engine (two engines) described is optimized to fly the HyperMach SonicStar aircraft at 62,000 ft, at a specific fuel consumption below 1.05 at Mach 3.3, this performance will be unprecedented and will welcome in a new era of the future of aerospace transport.

e.Electrical generation is provided by superconducting ring generators that are powered by the high velocity exhaust thrust from the combustor section of the engine.

f.The bypass fan is a twin fan system in which one fan counter rotates with the other fan, which reduces aerodynamic swirl and drag.

g.The bypass fan configuration is not constrained by a drive shaft, heavy gears and complex gear boxes, nor complex lubrication systems and it can be run at an optimal rotational speed so as to maximize its efficiency at any aircraft velocity, or altitude.

h.The bypass fans running independently from the compressor can be run at much slower speeds than the compressor, this means a more efficient RPM for the fan blade design of the S-MAGJET, a low bypass fan supersonic engine design.

i.Lower operating RPM speeds afford the use of wider blades, raising aerodynamic efficiency and thrust per horsepower, making the engine architecture greatly more efficient than the current art of engine designs.

j.Light weight superconducting ring motors with integrated cooling for the compressor do not require a drive shaft, nor the bypass fans or the superconducting ring generators of the power turbine, a “hollow-core shaft-less” tunnel is left in the center of the hybrid electric turbine which now carries additional bypass air.

k.Bypass air as the major component of thrust, rather than the hot exhaust from the power turbine being utilized as thrust is a more efficient method of producing thrust for propulsion in turbines.

l.Supersonic-Magnetic Advanced Generation Jet Electric Turbine (S-MAGJET), the majority of electric power produced off the power turbine via the superconducting ring generators is directed forward through a proprietary electric power management system to run the electric bypass fans and the electric compressor. This electrical independence of the bypass fan from the multi-stage axial compressor raises overall efficiency of the engine by 70% alone.