Next steps…

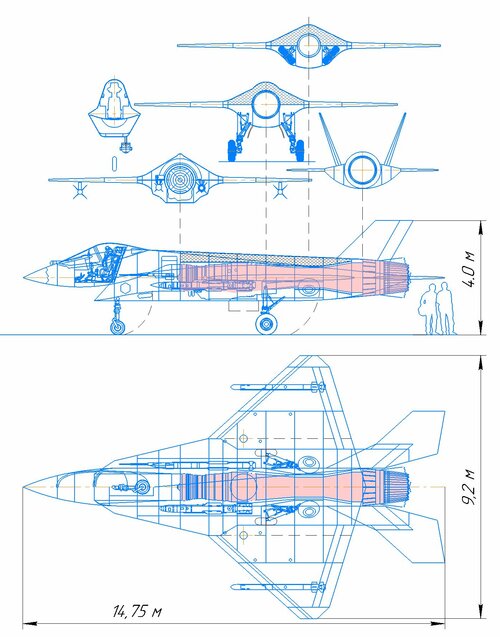

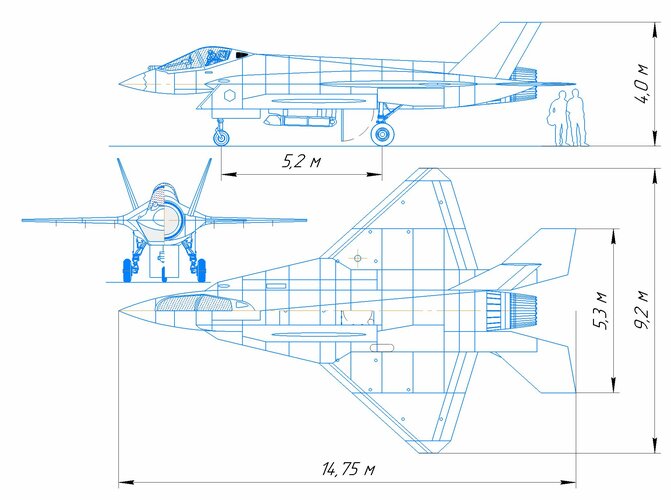

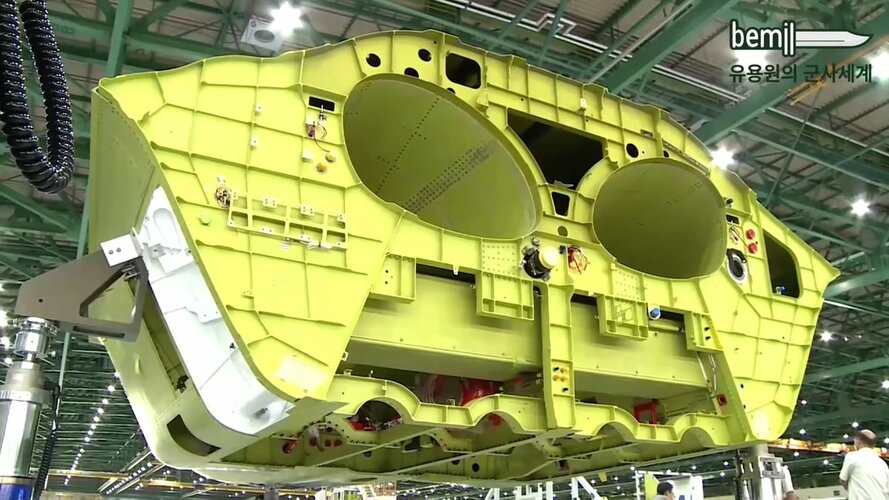

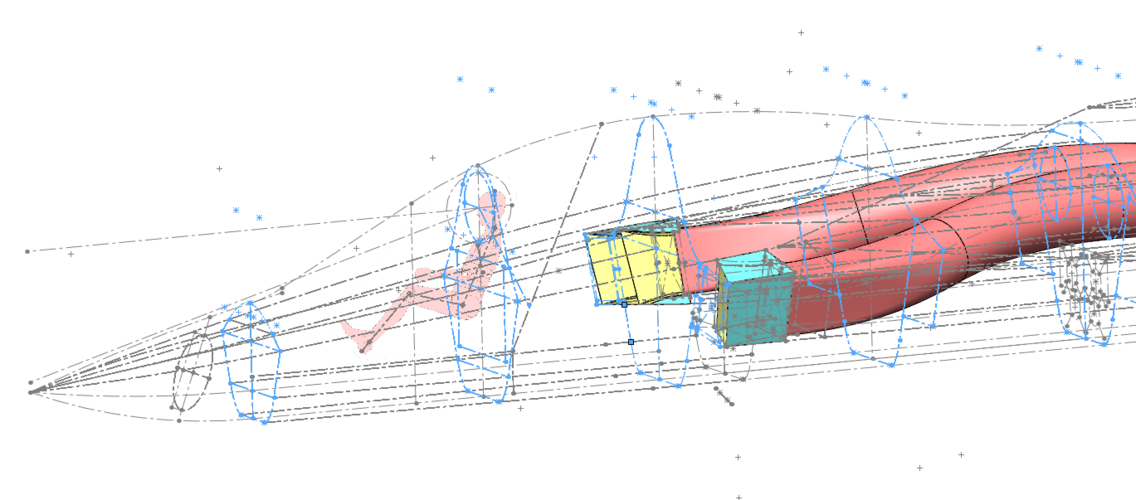

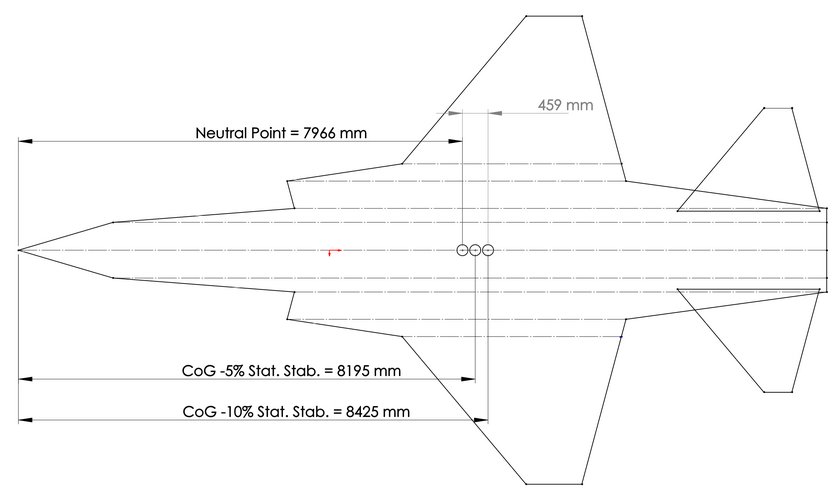

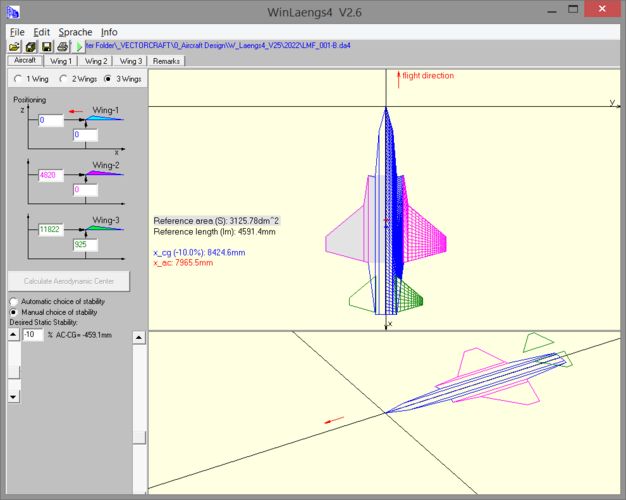

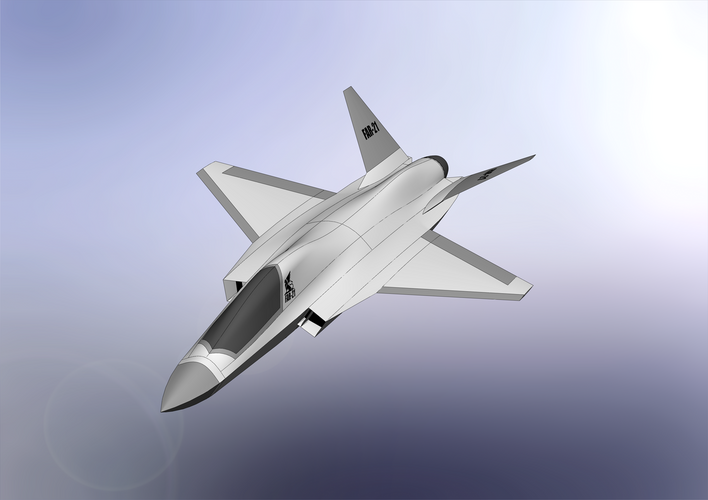

To be able to determine the location of the main landing gear and proceed with the fuselage design I have to decide on a wing and tail layout. Here is what I have so far:

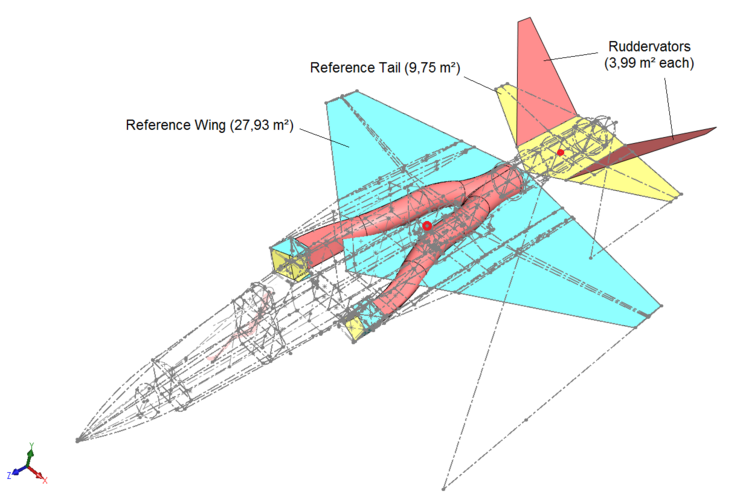

Reference Wing:

Span: 8,4 m (Gripen L)

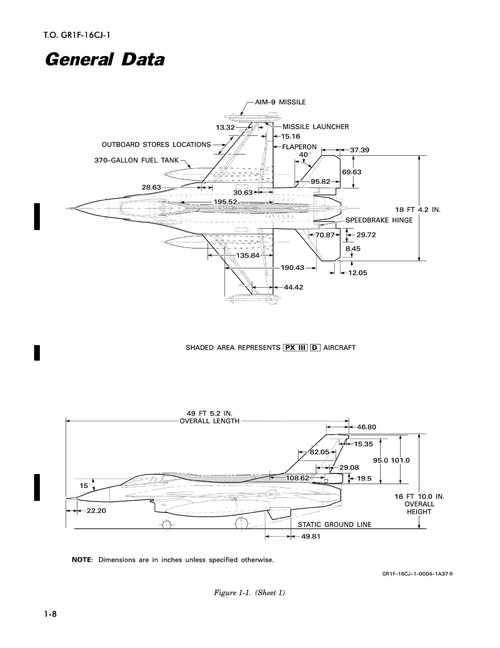

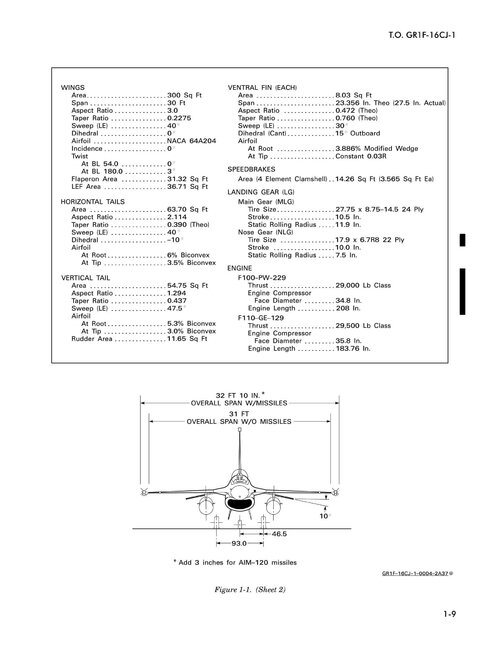

Reference Area: 27,93 m² (approx. F-16)

Aspect Ratio: 2,53

LE Sweep: 40° (F-16)

TE Angle: 15°

Reference Tail:

Span: 5,1 m

Reference Area: 9,75 m²

Aspect Ratio: 2,67

Ruddervators (V-Tail):

Dihedral Angle: 45°

True Area: 3,99 m² (each) => approx. 29% of wing reference area

Projected Area: 2,82 m² (each) => approx. 20% of wing reference area

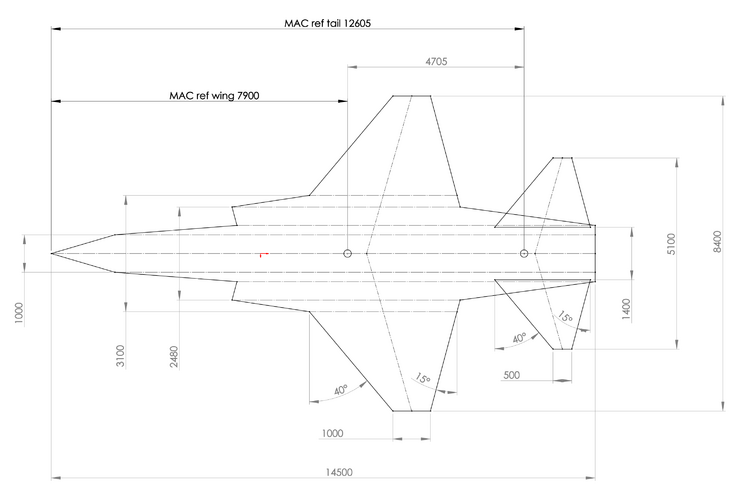

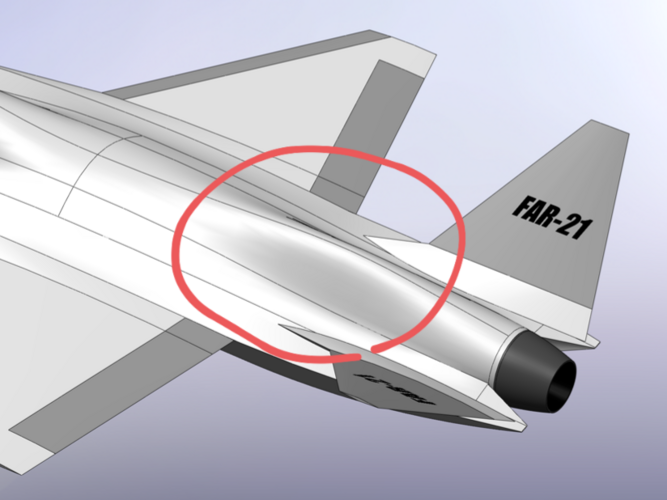

Fuselage Length: 14,5 m

Location of MAC-Wing relative to the Nose: 7,9 m (54,5% of fuselage length)

Distance MAC-Wing to MAC-Tail: 4,705 m

And for the sake of completeness:

Empty Weight: 7600 kg (Gripen NG)

Max. Weight: 16500 kg (Gripen NG)

Wing Loading (Empty): 272 kg/m²

Wing Loading (Max.): 591 kg/m²

Internal Fuel: 2821 l (2268kg @ 0,8kg/l) (Gripen L)

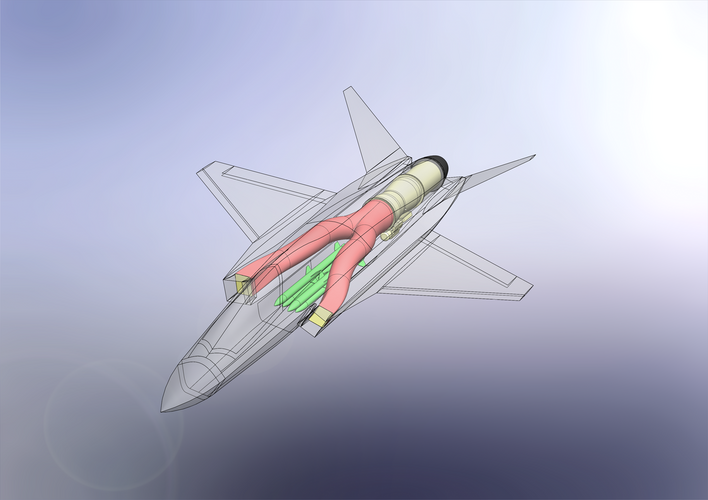

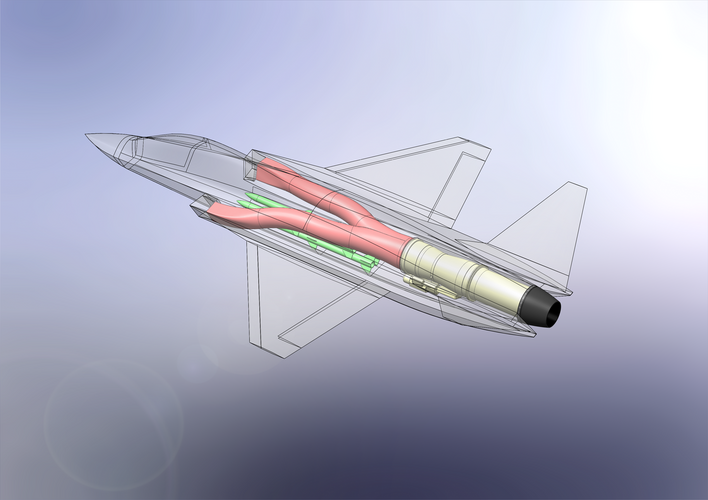

Engine: GE F414 (Gripen NG)

Thrust without AB: 63,47 kN

Thrust with AB: 97,99 kN

All of that is preliminary parameters. Comments welcome!

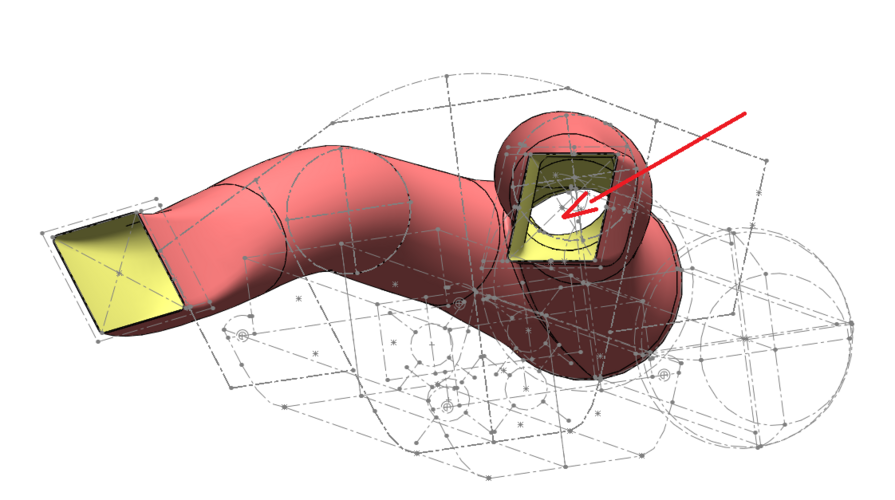

View attachment 671290