- Joined

- 26 May 2006

- Messages

- 34,902

- Reaction score

- 15,776

Hi,

www.researchgate.net

www.researchgate.net

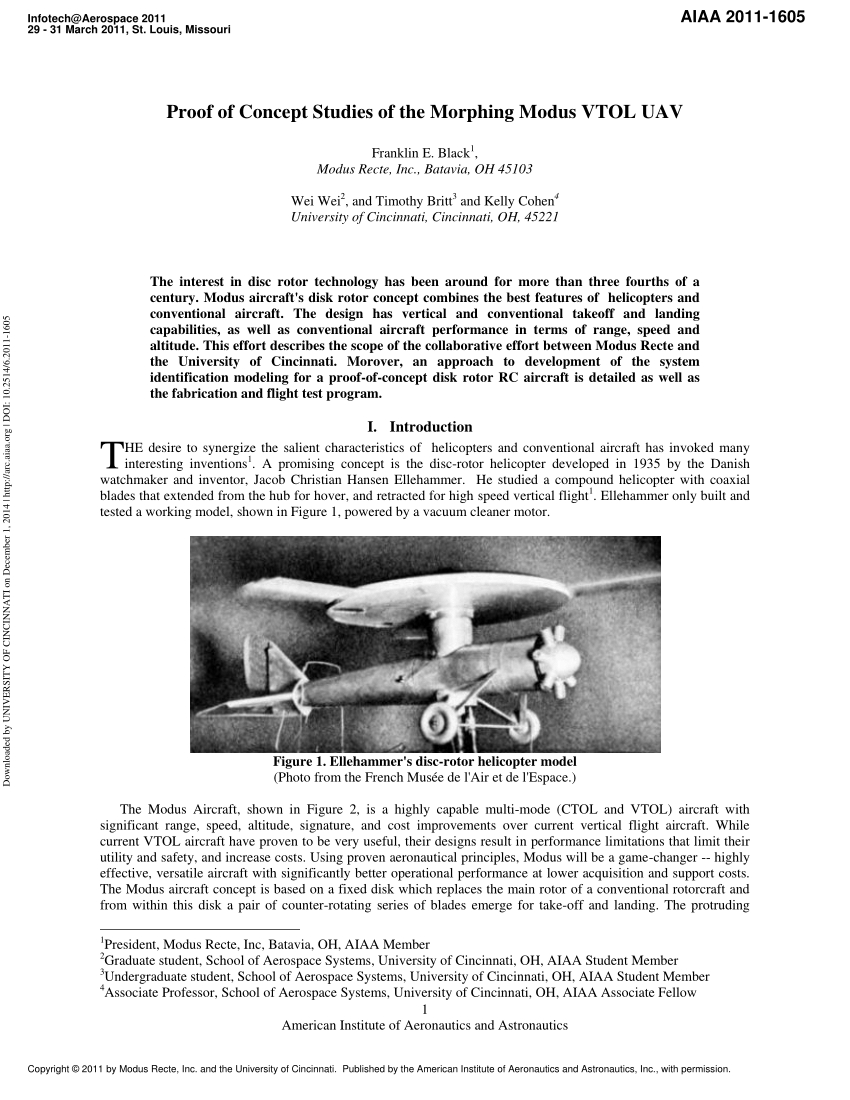

(PDF) Proof of Concept Studies of the Morphing Modus VTOL UAV

PDF | The interest in disc rotor technology has been around for more than three fourths of a century. Modus aircraft's disk rotor concept combines the... | Find, read and cite all the research you need on ResearchGate