Does anyone know about good pics of the BMW XII and XV, later labelled as BMW 112 and 115, as well as the later BMW 116 and 117? This interesting line of liquid cooled engines were discontinued in the late 30`s.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BMW liquid-cooled V12 engines

- Thread starter Wurger

- Start date

Captain Gremlin

ACCESS: Restricted

- Joined

- 13 October 2019

- Messages

- 1

- Reaction score

- 1

- Joined

- 8 March 2009

- Messages

- 1,056

- Reaction score

- 1,298

From: A Metallurgical Study of German and Italian Aircraft Engine and Airframe PartsBMW engine tests at Eisenach

The BMW company operate a repair and assembly plant and have extensive facilities for engine testing at Eisenach . The work on Mg was discussed with Dr. Friz , Technical Manager , and Dr. Christoph . Laboratory Director . This German engine firm is of particular interest for Mg because of their long - time utilization of Mg engine parts , their early installation of their own Mg foundry , and their experience with Mg crankcases in aircraft engines . Previous to the war BMW had built about 1,000 engines of the BMW 6 type with Mg crankcases . This was an in - line liquid - cooled engine of 700 horsepower . The experience with Mg in this engine was entirely satisfactory and Dr. Friz said he estimated the weight saving compared with an Al crankcase for this engine was about 20 %.

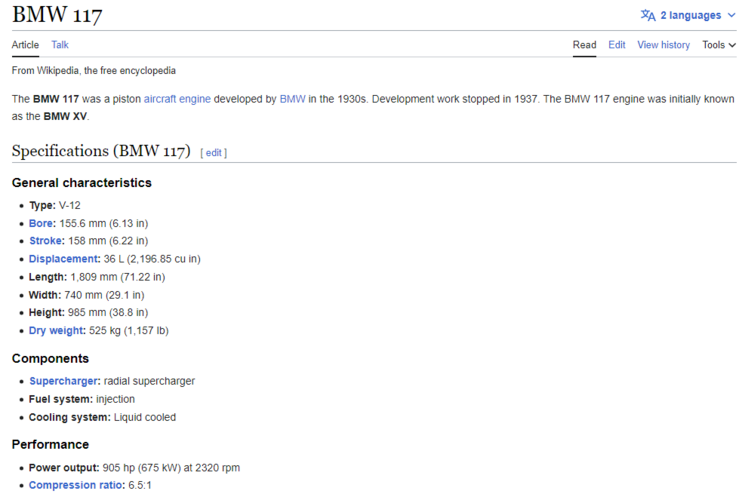

In 1936 BMW had practically completed their development and tests of the BMW 117 engine with a Mg crankcase. The BMW 117 is a 12 - cylinder, liquid-cooled, inverted V engine.

1200 HP with carburetor,

1450 H.P. with direct fuel injection ,

2700 R.P.M.

470 gm per horse power.

About twenty of these engines had been assembled for block and flight tests but the engine was never put into production because the BMW firm were engaged by the Government to produce radial engines . A photograph of the Mg crankcase of the BMW 117 is included with this report . Crankcases were also cast in Al alloy . In the early stages of development Dr. Christoph stated that the Mg crankcases did not have as long a test life as the Al due to the occurrence of cracks in the Mg at certain critical locations . He said that they were able to rectify this failure by polishing the Mg surface at these locations and that shot blasting would secure almost as good a result . As at Munich , it was not possible to secure any written reports on this surface treatment . As can be seen in the photograph , the upper half of the crank shaft is supported by an inset section bolted to the Mg crankcase. This inset is forged steel.