FutureSpaceTourist

ACCESS: Top Secret

- Joined

- 10 March 2010

- Messages

- 590

- Reaction score

- 34

Advent Launch Services was founded by a group of NASA retirees, led by Jim Akkerman.

From the history section of their website:

Details of their VTHL spaceplane X-prize entry are attached. The following Advent vehicle and mission information is part of the PDF file from http://space.xprize.org/ansari-x-prize/advent-launch-services:

From the history section of their website:

Advent Launch Services was formed in 1999, but the Advent concept started long before that. As part of the Future Programs Office at NASA’s Johnson Space Center, several individuals were studying ways to make the Shuttle program more cost-efficient. At the time (1990), NASA was considering boosters using liquid propellants to replace the solid propellant boosters for the Shuttle system. The initial cost analysis of the Shuttle system prompted the team’s engineers to consider features for a launcher concept that could achieve minimum cost. This was the beginning of the Advent system.

The project was an unofficial effort, done whenever there was a little time available, truly a labor of love. About a year later, a concept materialized. The concept was named Advent because it represented a new beginning for space activities. The project’s detailed cost analysis thoroughly convinced the team that orbit delivery could cost about thirty dollars per pound instead of several thousand dollars per pound. The group submitted a formal proposal to NASA in 1992, but the program concepts were never adopted. NASA even relinquished the patent rights to the special features of the Advent concept.

Now retired, the original group of engineers who began the Advent journey have competed in the ANSARI X PRIZE competition, and completed a prototype launcher with very encouraging results.

Details of their VTHL spaceplane X-prize entry are attached. The following Advent vehicle and mission information is part of the PDF file from http://space.xprize.org/ansari-x-prize/advent-launch-services:

Vehicle Specifications

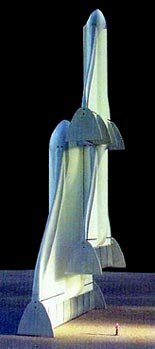

- Name: Advent

- Length: 35 feet

- Diameter: 4.75 feet (12 ft wingspan)

- GTOW: 12,600 lbm

- Dry Weight: 4,100 lbm

- Crew Capsule: 8 feet long, 4.5 feet in diameter

- Crew Environment: Cabin pressurized to 1 atm with no pressure suits

- Payload Capacity: 600 lbm

- No. of Engines: 1

- Propulsion System: Pressure fed

- Fuel: Liquid Methane

- Oxidizer: Liquid Oxygen

- Total Thrust: 18,900 lbf

- Reaction Control System: Cold gas methane

Mission Specifications

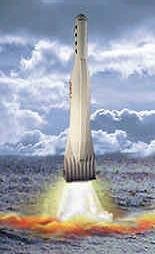

- Alt. at Ignition: From within the ocean

- Orientation at Ignition: Vertical

- Max. Accel. Force on Ascent: 4.6 g

- Alt. at Engine Cut-off: 145,000 feet

- Time at Engine Cut-off: 97 seconds

- Max. Speed: 3,600 feet/second

- Max. Altitude: 105 kilometers

- Time in Weightless Conditions: 220 seconds

- Reentry Method: Aerodynamic controlled glide

- Accel. Forces on Descent: 5.2 g

- Landing Method: Winged rocket designed to glide down to ocean surface for a safe, controlled, horizontal landing

- Total Duration: 13 minutes

- Landing Distance from Takeoff Location: 0 kilometers

- Time Between Missions: approx. 4 hours