alberchico

I really should change my personal text

- Joined

- 14 January 2014

- Messages

- 708

- Reaction score

- 1,514

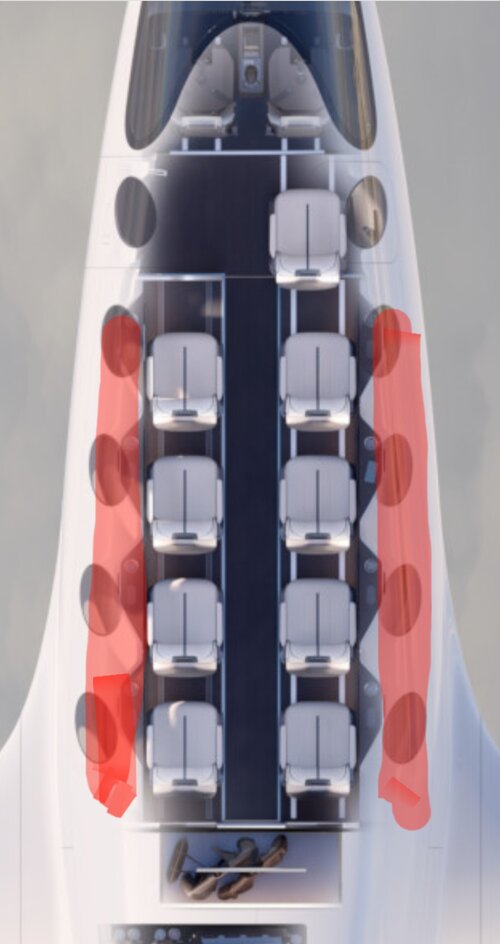

Regardless about how one feels about the prospects of this project, you have to admit that is one gorgeous looking aircraft.

Edit: Flight testing was originally supposed to take place in Arizona to take advantage of the year round near perfect weather but after an investment firm acquired a large stake in the company they moved flight testing up to the Pacific Northwest so they could be closer to the engine maker to be able to resolve problems quicker. Apparently now the winter weather has wrecked havoc on their flight testing schedules. Should have just stuck to the original plan of doing all the test flights in the South.

Also it looks like the head of both Eviation and the engine maker they are using has stepped down just before the first flight. Odd timing.

I'm also surprised the prototype doesn't have the company name or logo painted on it.

www.geekwire.com

www.geekwire.com

Edit: Flight testing was originally supposed to take place in Arizona to take advantage of the year round near perfect weather but after an investment firm acquired a large stake in the company they moved flight testing up to the Pacific Northwest so they could be closer to the engine maker to be able to resolve problems quicker. Apparently now the winter weather has wrecked havoc on their flight testing schedules. Should have just stuck to the original plan of doing all the test flights in the South.

Also it looks like the head of both Eviation and the engine maker they are using has stepped down just before the first flight. Odd timing.

I'm also surprised the prototype doesn't have the company name or logo painted on it.

Electric aviation executive Roei Ganzarski steps down from leadership roles at MagniX and Eviation

Roei Ganzarski, the former Boeing manager who went on to give a boost to all-electric aviation, is leaving his executive posts at MagniX and Eviation Aircraft.

Last edited: