Got this form Groggy on the TGP site

http://www.tgplanes.com/Public/snitz/topic.asp?TOPIC_ID=1268

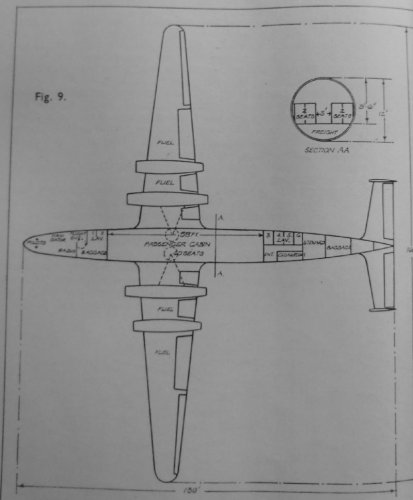

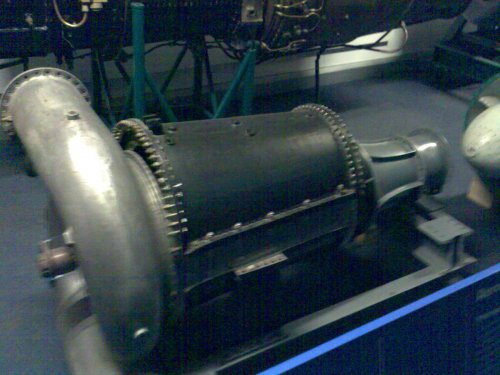

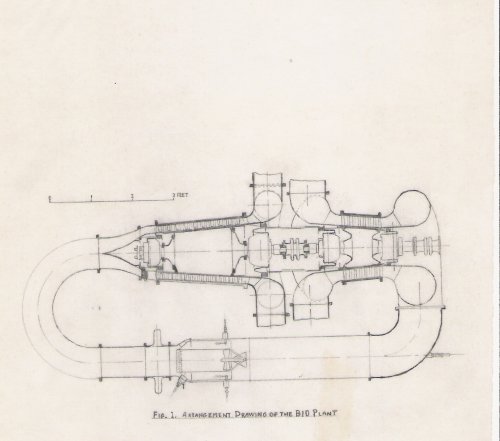

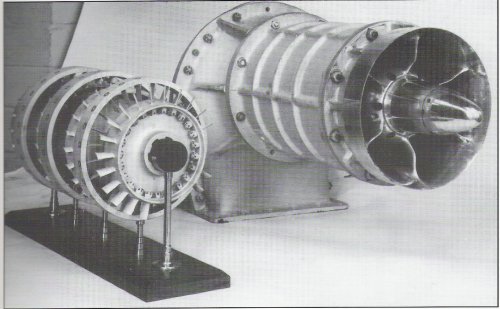

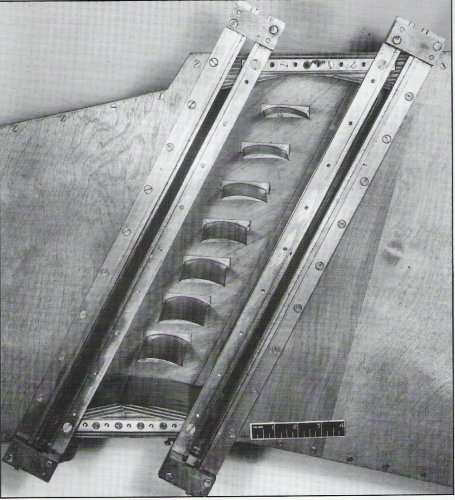

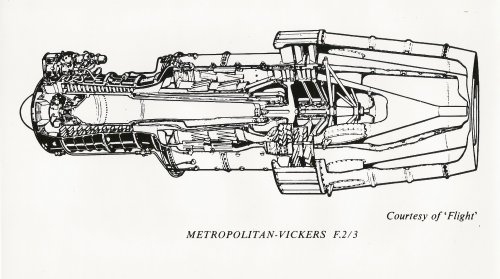

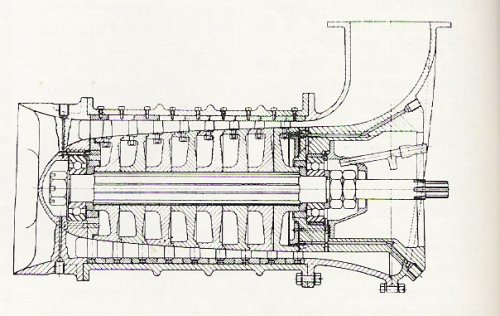

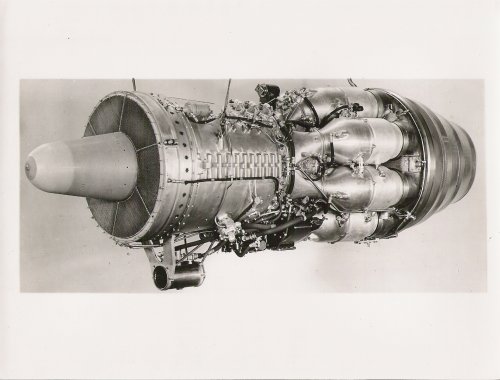

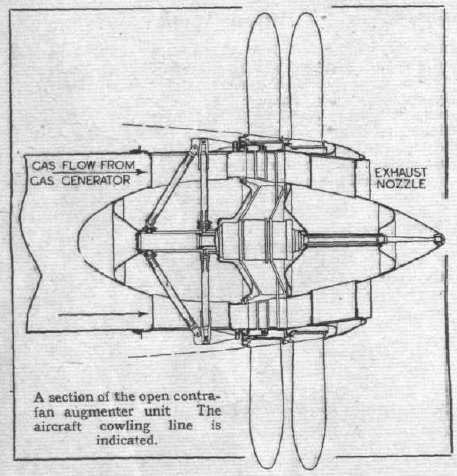

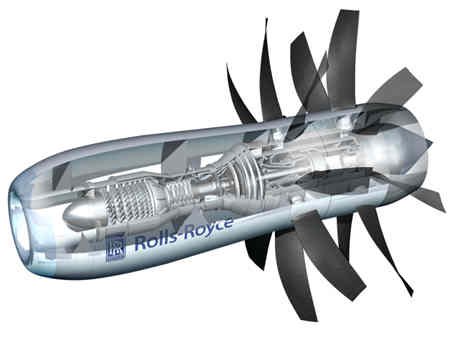

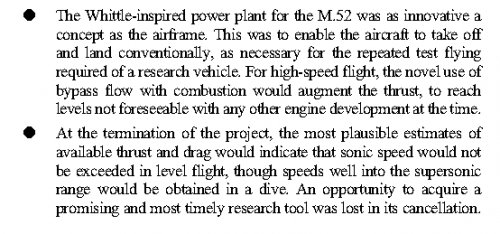

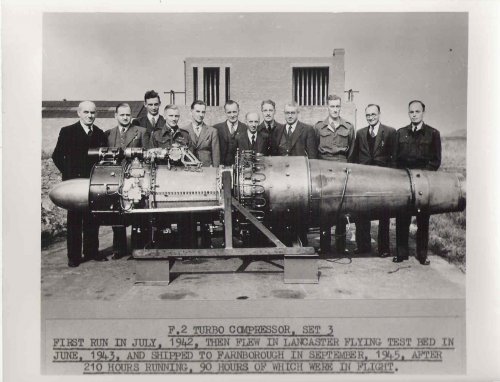

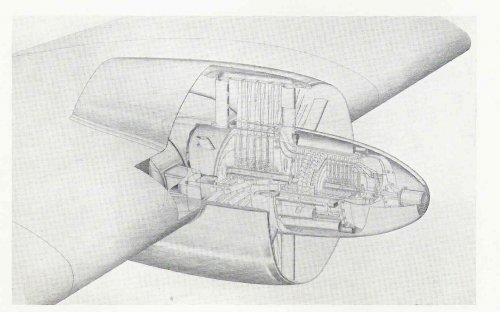

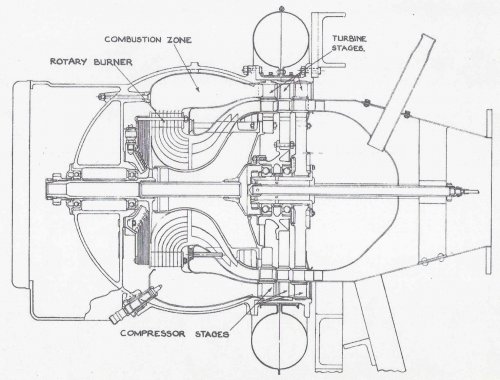

“The L.R.1 bomber project was first submitted to the Ministry of Aircraft Production late in 1944” and “In May, 1945 a project was prepared for a transatlantic civil transport powered by four L.R. 1 engines driving ducted fans. The machine was designed to cruise at 470 m.p.h. at 45,000ft. with a still air range of 5,280 miles and a payload of 20,000 lb. The estimated all-up weight was 156,000 lb.”

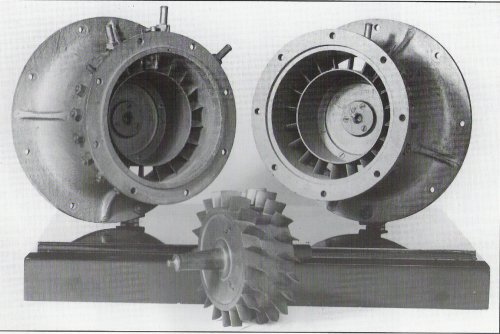

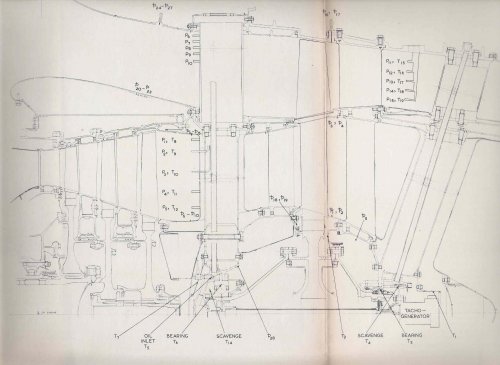

“The static thrust of the straight jet version of the engine was envisaged as 5,500lb static thrust at S.L.” The L.R.1 turbo fan would have given with a bypass ratio of 2.5, so this would give a thrust of ?? 10,000 lb? any ideas?

This is about the only details I can find for the L.R. 1 bomber but I was told by Ian Whittle, Whittles son that the prototype L.R.1 engine was almost finished being built.

Any additions or comments?

Anybody have any further information on the bomber, the civilain transport or the engines and what would have been the effect on the early post war designs if a turbofan had been available in the late 40's

http://www.tgplanes.com/Public/snitz/topic.asp?TOPIC_ID=1268

“The L.R.1 bomber project was first submitted to the Ministry of Aircraft Production late in 1944” and “In May, 1945 a project was prepared for a transatlantic civil transport powered by four L.R. 1 engines driving ducted fans. The machine was designed to cruise at 470 m.p.h. at 45,000ft. with a still air range of 5,280 miles and a payload of 20,000 lb. The estimated all-up weight was 156,000 lb.”

“The static thrust of the straight jet version of the engine was envisaged as 5,500lb static thrust at S.L.” The L.R.1 turbo fan would have given with a bypass ratio of 2.5, so this would give a thrust of ?? 10,000 lb? any ideas?

This is about the only details I can find for the L.R. 1 bomber but I was told by Ian Whittle, Whittles son that the prototype L.R.1 engine was almost finished being built.

Any additions or comments?

Anybody have any further information on the bomber, the civilain transport or the engines and what would have been the effect on the early post war designs if a turbofan had been available in the late 40's