Some interesting things about the Republic Rainbow utilizing exhaust thrust.

View attachment 693821

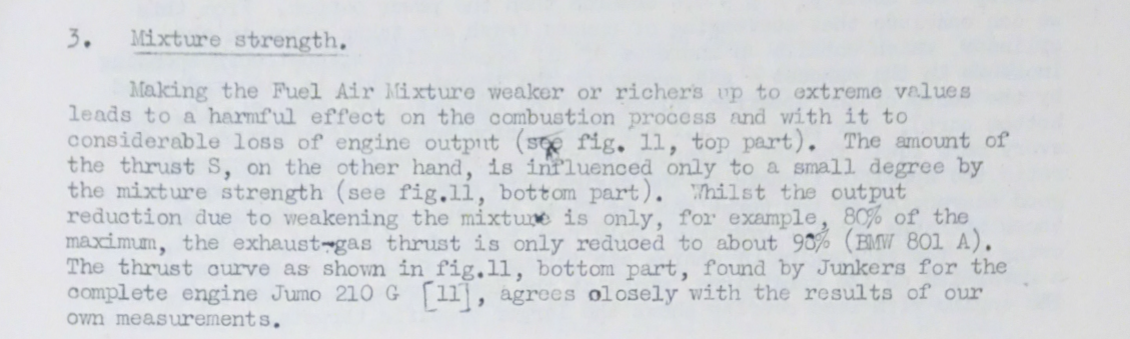

Instead of dumping the waste gate exhaust off to the side like on the P-47, the waste gate gas was fed into the turbo exhaust. In this way all of the exhaust gas came out the same exit giving a pretty significant boost at lower altitudes. Here the dotted line is the dumped exhaust and solid the recombined exhaust.

View attachment 693822

A variable area exit was used to further boost the exhaust thrust.

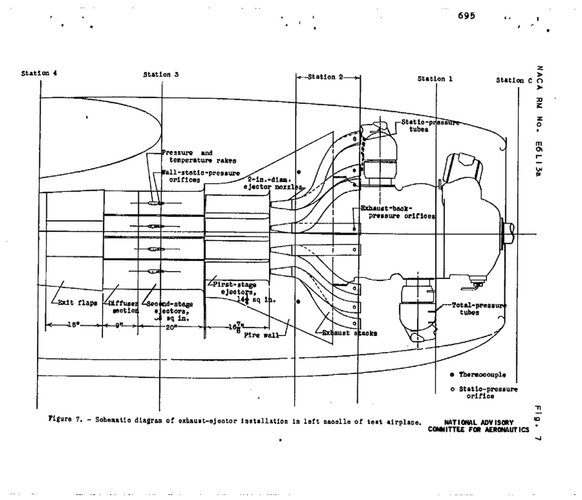

View attachment 693820

Lastly, a comparison between the Rainbows installation and a 'typical' one. There is a typo in the net BHP on the right column; it should be 2409 not 4209.

source; https://www.emerald.com/insight/content/doi/10.1108/eb031588/full/html

Highly interesting! And thanks for clearing up this typo thing ...