@sienar

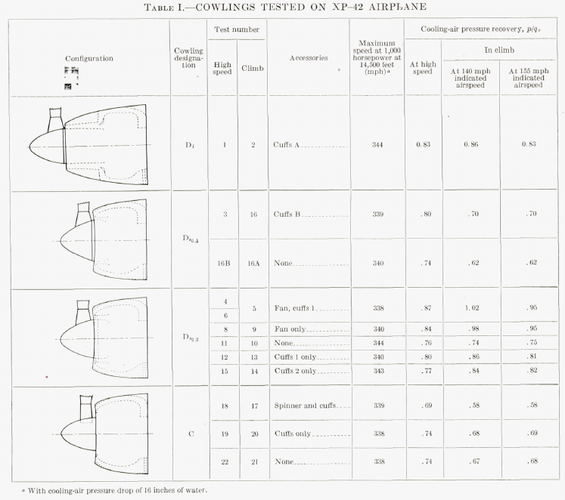

Still you didn’t get that thing with the reference area. The Cd value in David’s paper is referred to the wetted area and because the Spitfire Mark IX has more wetted area than the FW190, it has a lower cd value despite having a higher absolute drag. If David would have used the frontal area as reference, the Cd value of the FW-190 with its bulkier fuselage would have been lower. Despite that, what really matters is the absolute drag (zero lift drag) and no matter which Cd you are using, the FW190 A has a lower drag than the Spitfire IX.

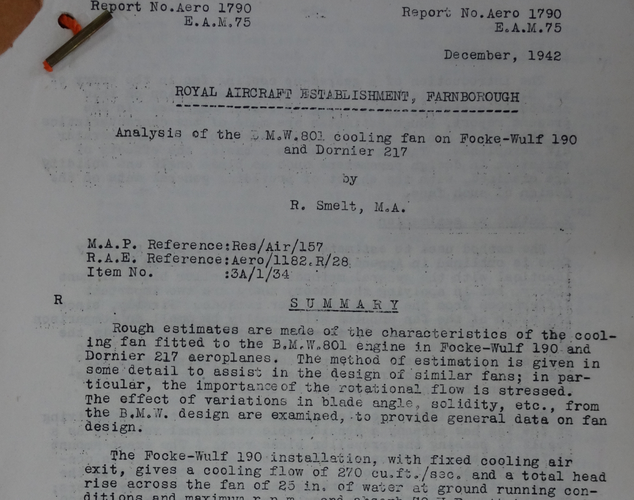

I guess, David didn’t include a rotating fan in his calculation, if so, the drag of the FW190 would be even lower, because the fan is pushing out the air with power from the engine.

I would recommend you, not to read too many complicate books about aerodynamic before you didn’t understand the fundamentels:

“Notice that the area (A) given in the drag equation is given as a

reference area. The drag depends directly on the

size of the body. Since we are dealing with

aerodynamic forces, the dependence can be characterized by some area. But which area do we choose? If we think of drag as being caused by friction between the air and the body, a logical choice would be the total surface area of the body. If we think of drag as being a resistance to the flow, a more logical choice would be the frontal area of the body that is perpendicular to the flow direction. And finally, if we want to compare with the lift coefficient, we should use the same wing area used to derive the lift coefficient. Since the drag coefficient is usually determined experimentally by measuring drag and the area and then performing the division to produce the coefficient, we are free to use

any area that can be easily measured. If we choose the wing area, rather than the cross-sectional area, the computed coefficient will have a different value. But the drag is the same, and the coefficients are related by the ratio of the areas. In practice, drag coefficients are reported based on a wide variety of object areas. In the report, the aerodynamicist must specify the area used; when using the data, the reader may have to convert the drag coefficient using the ratio of the areas." (

https://www.grc.nasa.gov/www/k-12/airplane/drageq.html)