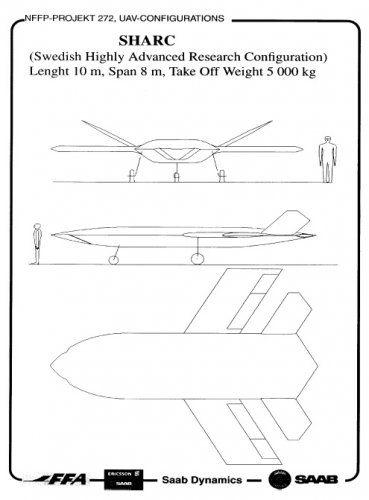

Since the late 90-ies SAAB had been carrying out preliminary studies about several Unmanned Aerial

Vehicles (UAV) concepts but not taking them into flying demonstrators. In 2001 it was decided to start the

SHARC Technology Demonstrator (SHARC TD) project: a small dedicated team was given the task to

develop, manufacture and flight test an UAV system including an avionic system and a Ground Control

Station (GCS) that could be re-used later in a second demonstrator called FILUR (see Figure 1).

Because of a limited budget and good in-house experiences from flight tests of instrumented sub-scale

aircraft, it was decided that the SHARC TD should be in 1:4 scale of the original SHARC design. One of

the major goals of the project was to test the airworthiness process for a military UAV, and this could well

be achieved even with sub scaled aircraft. Even the goal of testing a lean development process for

demonstrators could be achieved in that way.

The SHARC TD project was initiated in 2001 with first flight less than one year later, on February 11th

2002, with the basic version. The more advanced version made its maiden flight on April 9th 2003, less

than two years after project start. In September 2003 the SHARC flew a number of missions out of visual

range, ranging around 20 km from the control station location. In January 2004 the effort towards the

development of the ATOL functionalities was initiated, and led to a successful flight test campaign in

August 2004, during which fully autonomous mission were demonstrated, from standstill to standstill

(Figure 2). The details about this latter effort are the object of this paper.

The SHARC system is composed by two flying demonstrators (BS-001 and -002), a GCS and some GSE

for engine start and cooling air supply on ground. A basic version of the flying platform is available in two

units (BT-001 and -002), called Trainer Model, used for early aerodynamic and flying qualities

evaluations, and still in service for pilot training.

The SHARC TD is a 60 kg jet-engine driven aircraft. A fixed robust tricycle landing gear has been chosen

taking into account the tests of autonomous take-off and landing (direct landing without flare); COTS

components have been used as much as possible (engine, servos, valves, many sensors, etc.). The airframe

is manufactured in light-weight composite materials; the airframe weighs only 8 kg (without landing gear).

The payload consists of a forward looking colour video camera.

The avionic system (hardware and software) is designed and manufactured by SAAB and is based on

Flight Test Instrumentation system COMET 15 used in the Gripen and Viggen fighter a/c. Before the

decision to develop an in house avionic system, a market survey was conduced, but no existing system

was fulfilling specifications. Electro-optic fibres, or “fly-by-light”, are used to the actuators in order to

minimize the risk for Electro Magnetic Interference. SHARC has a complete FTI with a SAAB designed

and manufactured nose-boom.

Many software functions are re-implementations of existing algorithms previously developed for other

SAAB aircrafts: the waypoint navigation algorithm comes from the AJ 37Attack-Viggen and AHRS from

JA37 Fighter-Viggen and JAS 39 Gripen.

SWED- Saab UCAV concept.jpg5.1 KB · Views: 577

SWED- Saab UCAV concept.jpg5.1 KB · Views: 577 SWED- Saab UCAV concepts.jpg10.7 KB · Views: 586

SWED- Saab UCAV concepts.jpg10.7 KB · Views: 586 SWED- Saab Sharc UCAV early_1.jpg3.1 KB · Views: 570

SWED- Saab Sharc UCAV early_1.jpg3.1 KB · Views: 570 SWED- Saab Sharc UCAV early_2.jpg173.8 KB · Views: 157

SWED- Saab Sharc UCAV early_2.jpg173.8 KB · Views: 157 SWED- Saab Sharc UCAV early_3.jpg69.2 KB · Views: 146

SWED- Saab Sharc UCAV early_3.jpg69.2 KB · Views: 146 SWED- Saab Shrac UCAV_0.jpg29.5 KB · Views: 147

SWED- Saab Shrac UCAV_0.jpg29.5 KB · Views: 147