You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Non-Pneumatic Tire

- Thread starter Creative

- Start date

Matej

Multiuniversal creator

SAAB and BMW tested this technology a few years ago, but if I remember correctly, the biggest problem was the short life cycle of the tire. Also it can absorb much bigger undulation of the surface, what led the drivers naturally to drive harder, shortening the short life cycle even more.

- Joined

- 11 March 2006

- Messages

- 8,608

- Reaction score

- 3,061

Yup, never got anywhere. Maximum speed was too limited for the commercial passenger car market. Don't know what limited maximum speed, vibrations or heat buildup...?AeroFranz said:I thought there was something similar from Michelin called 'Tweel"

dogsbody

ACCESS: Restricted

- Joined

- 26 November 2007

- Messages

- 22

- Reaction score

- 13

A similar type of tire was tried out on the skidsteers (bobcat type ) at work, a couple of years ago, at the ore processing plant where I work. These are used to clear-up spillage under our feeders and conveyors. During the warm summer hours, they worked fairly well, but winter was another story. In the sub-zero temperatures, the driver noted severe vibrations in the cab. The voids in the tires had packed with frozen dirt, the tires themselves were frozen solid and were being driven over frozen, uneven ground. The tires wore out very quickly, too.

The company soon switched back to pneumatic tires.

Chris

The company soon switched back to pneumatic tires.

Chris

- Joined

- 27 May 2007

- Messages

- 676

- Reaction score

- 36

The clever working of the pneumatic tire is that a bump is absorbed by the air volume in the whole tire. This leads to all kinds of good things like linearity and structural efficiency, compared to those mechanical tires.

- Joined

- 6 November 2010

- Messages

- 4,228

- Reaction score

- 3,164

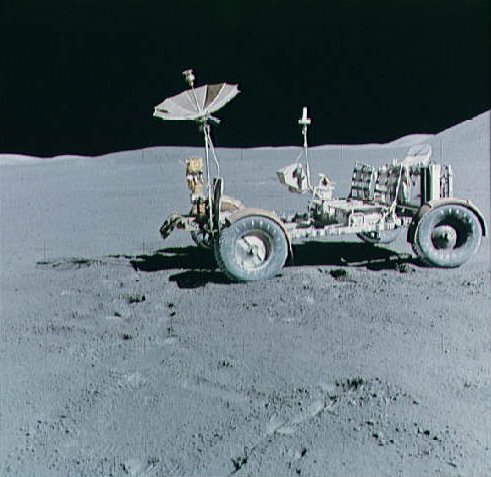

NASA's lunar rover had woven wheels.

Using pneumatic tires on a rocky surface in a vacuum environment would have been an interesting experiment, NASA passed on the opportunity of finding out what would happen. Can't think why...

Source: http://nssdc.gsfc.nasa.gov/planetary/lunar/apollo_lrv.htmlThe wheels consisted of a spun aluminum hub and an 81.8 cm diameter, 23 cm wide tire made of zinc coated woven 0.083 cm diameter steel strands attached to the rim and discs of formed aluminum. Titanium chevrons covered 50% of the contact area to provide traction. Inside the tire was a 64.8 cm diameter bump stop frame to protect the hub. Dust guards were mounted above the wheels. Each wheel had its own electric drive, a DC series wound 0.25 hp motor capable of 10,000 rpm, attached to the wheel via an 80:1 harmonic drive, and a mechanical brake unit. Manuevering capability was provided through the use of front and rear steering motors. Each series wound DC steering motor was capable of 0.1 hp. Both sets of wheels would turn in opposite directions, giving a steering radius of 3.1 meters, or could be decoupled so only one set would be used for steering. Power was provided by two 36-volt silver-zinc potassium hydroxide non-rechargeable batteries with a capacity of 121 amp-hr. These were used to power the drive and steering motors and also a 36 volt utility outlet mounted on front of the LRV to power the communications relay unit or the TV camera. Passive thermal controls kept the batteries within an optimal temperature range.

Using pneumatic tires on a rocky surface in a vacuum environment would have been an interesting experiment, NASA passed on the opportunity of finding out what would happen. Can't think why...

Attachments

Similar threads

-

-

-

-

-

Donald S. Mitchell's 1946 Goodyear Racer flying wing design

- Started by Stargazer

- Replies: 11