marauder2048

"I should really just relax"

- Joined

- 19 November 2013

- Messages

- 3,157

- Reaction score

- 926

Now if you could convince the US Navy to have that as the single fuel at sea...Here's JP-5 for the combustion chamber,

Now if you could convince the US Navy to have that as the single fuel at sea...Here's JP-5 for the combustion chamber,

The thought occurred...but my guess is that the additives/refining that make JP-5 viable at low temperatures and stable at higher temperatures makes it more expensive than good old NATO F-76.Now if you could convince the US Navy to have that as the single fuel at sea...Here's JP-5 for the combustion chamber,

Converting the propulsion and electric generating systems of ships to use of JP-5 would not be

detrimental to fleet operational readiness. However, few, if any, operational or maintenance

benefits would be realized from such a conversion. Benefits realized would most probably occur

in the logistics area through the simplicity of handling only one fuel. These benefits are very

difficult to quantify, and may not be fully realized if it is still desirable to fully segregate the fuel

to be used for aviation from ship fuel.

Due to the higher cost of JP-5, increased fuel requirement, and the necessity of cleaning

numerous fuel storage tanks, such a conversion would, at least initially, be very costly for the

U.S. Navy. It also seems unlikely that the higher volumes of JP-5 would result in significant

price reductions; in some markets the price may increase due to increased refining requirements.

Yes, the standard prices which is a bit of an accounting thing insulate the services a bit from the market swings. The moving averages so far this fiscal yearDLA current fuel prices (October 2020):

F-76: $2.39

JP-5: $2.40

Lot's of great memories from Edwards. Met Neil Armstrong while there, he punched me in the arm at SETP, Chuck Yeager literally ran into me at an aircrew safety briefing, he was too busy talking to Maj Gen Pearson (F-15 ASAT) to pay attention to where he was going, worked with Gordan Fullerton when he augmented a crew for a 24 hour mission when I was getting my test conductor qual, flew with Rogers Smith at National, one of the recent occupants of ISS and I worked a special test program together, IFE'd an Undersecretary of the AF and former Shuttle astronaut on a mission I conducted, and many more great memories. The challenge is not to ramble on too much about them...That's a great piece to have in your memoirs, nicely done, Sir.

My paternal uncle is after me to write a book with him about my AF career, hated English and writing, that's why I went for engineering before going to business school, lol. That MBA thing is the thing holding me back, since I'm not really sure there's enough of a market for the non-pilot types to write books about sitting in the back of airplanes running special instrumentation or sitting in a control room conducting tests making sure all of the data is captured.Thank you for all that you have done, we all benefit from that, never tire of hearing that sort of story either so perhaps you should consider writing a book about it? Thanks to all the engineers, designers, technicians and flight crews etc here, what you have done and are doing makes us all richer. To infinity and beyond folks, it started with yourselves and folk like you. Bravo.

The standard free-space ship RCS in m^2 is approximated by:Ship RCS is more or less quadratic in displacement.If CVNs are doomed by the threat of anti-ship missiles of all types (and I don't believe they are) there is no reason CVLs would not be.

CATOBAR launch and recovery is both readily detectable and unmistakeable to OTH radars.

Infrared signature is heavily dependent on projected area; carriers are pretty much all normals so smaller is better.

Acoustically, CATOBAR carriers are (EMALS notwithstanding) horrible.

Are you saying Ship's RCS is proportional to ship's displacement? If so, I think you are incorrect.

σ = 52 * f ^(1/2) * D ^(3/2)

D is the full-load displacement of the vessel in kiloton

f is the radar frequency in MHz

You'll find it used pretty much..everywhere.

Aircraft carriers cannot typical replenish fuel while conducting high intensity flight ops and longer aircraft distances imply greater fuel consumption per aircraft.I do not see a relationship with the two data points: how often the ship has to refuel vs how far the aircraft can fly.

The last RAND study ended up recommending a Forrestal sized CVN LX which has a smaller embarked airwing than the POR CVN-80+.If everyone starts with same assumption that the number of aircraft that have to be deployed is fixed, the answer will always come back that the most cost effective solution is large carriers. All the RAND reports make that assumption so they always come back with the same recommendation i.e. keep doing the same. Which means more and more expensive carriers.

It's very hard to achieve meaningful signature reductions in the HF against OTHR and surface wave radars.The standard free-space ship RCS in m^2 is approximated by:Ship RCS is more or less quadratic in displacement.If CVNs are doomed by the threat of anti-ship missiles of all types (and I don't believe they are) there is no reason CVLs would not be.

CATOBAR launch and recovery is both readily detectable and unmistakeable to OTH radars.

Infrared signature is heavily dependent on projected area; carriers are pretty much all normals so smaller is better.

Acoustically, CATOBAR carriers are (EMALS notwithstanding) horrible.

Are you saying Ship's RCS is proportional to ship's displacement? If so, I think you are incorrect.

σ = 52 * f ^(1/2) * D ^(3/2)

D is the full-load displacement of the vessel in kiloton

f is the radar frequency in MHz

You'll find it used pretty much..everywhere.

I'm afraid those formulae are of little or no value against a target ship that has taken measures to reduce its RCS i.e. modern warships.

Sortie duration generally dictates fuel consumption; it's the high intensity ops that refueling precludes and carriers will typically withdraw

1. Your comment doesn't address the relationship between the two data points. Smaller ship tanks means more frequent refueling and has no relevance to sortie duration. BTW, QE showed the ability to perform FJ ops while refueling on her very first set of F-35B trials. There's no reason to suppose high sortie rates could not be maintained.

They were directed to look at lower cost alternatives which included a cost scrubbed Ford.2. Not really. If by recent RAND study you mean the "Future Aircraft Carrier Options", RAND started with the assumption that the Ford's should be replaced and suggested a smaller carrier should be studied as a replacement. RAND did not recommend Ford's be replaced with a smaller carrier because they were not asked that question.

And carriers don't really have hull forms amenable to the shaping required at other frequencies.

Very interresting. Are there some details on these new CVL? Thx in advance.

OSD/CAPE plan is to increase the carrier fleet from 11 to 14 by building/sustaining 6 CVLs for half the cost if not more of 3 CVNs.

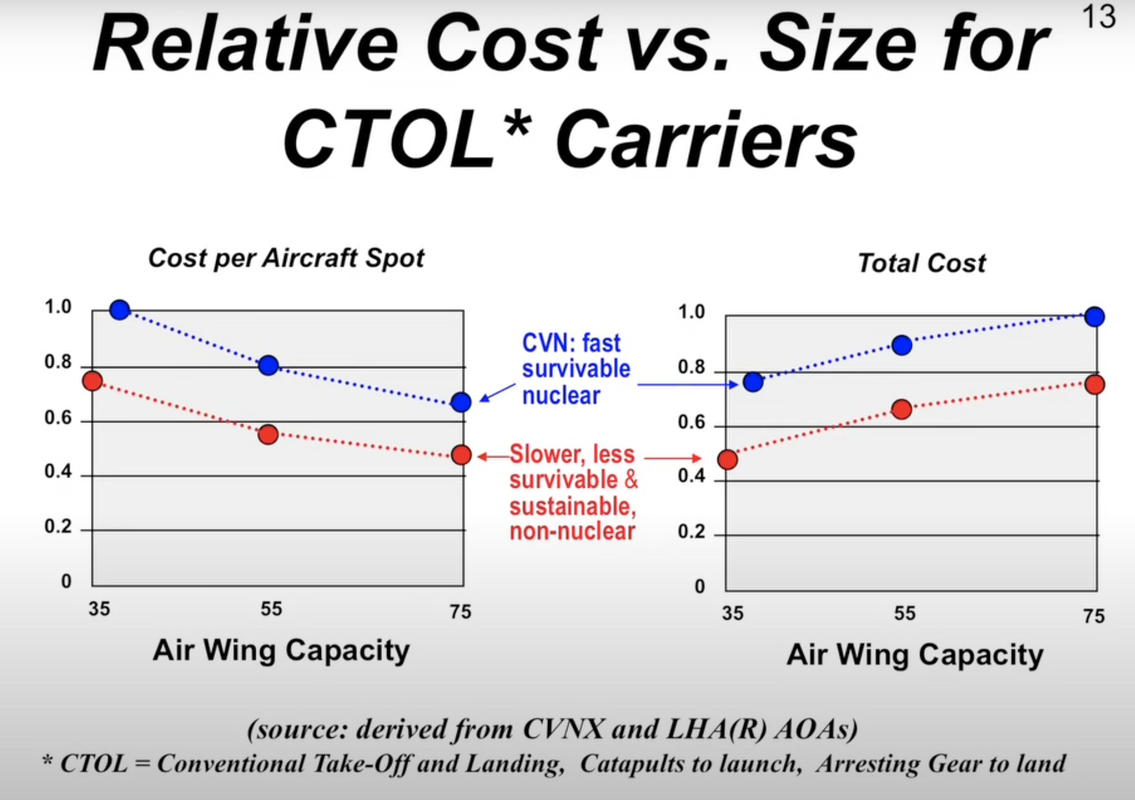

@H_K Excellent find, the good Adm. did a quite good job of breaking down requirements and demonstrating traceability. He did a good job explaining why 20 yrs ago they chose CVN-78. Everything lines up with DoD 5000.1. The choice between medium and large, even large nuclear/large conventional is pretty clear when everyone has to pay the NRE for all of new tech. It would be nice to see the trade or sensitivity studies around sizing and the various types of conventional propulsions, but that's probably not for public consumption...Might also be worth looking at the old CVNX studies from the 90s... those seemed to indicate that you could buy 3 medium CVs for the price of 2 large CVNs.

The 3 medium CVs would be slightly cheaper per aircraft spot and could carry slightly more total aircraft (3x 55=165 aircraft vs. 2x 75=150 aircraft). However in some scenarios with mainly short range sorties the larger CVNs would be more efficient due to less crowded decks.

From Capt Tal Manvel's lecture on CVN-78:

Shifley Lecture: USS Ford-class carrier design

(personally I find him very biased in favor of CVN-78, but still has some interesting slides)

With automated landing systems improving the accuracy of aircraft landings, perhaps alternative hull forms is viable for traditional aircraft as well, especially in in cases of lighter aircraft.And carriers don't really have hull forms amenable to the shaping required at other frequencies.

Well, if you use STOVL, you could play with hull shapes quite a bit more than usual. For example, trimaran shape with narrow launch decks in side hulls & landing deck at the stern of central hull.

With automated landing systems improving the accuracy of aircraft landings, perhaps alternative hull forms is viable for traditional aircraft as well, especially in in cases of lighter aircraft.

OSD/CAPE plan is to increase the carrier fleet from 11 to 14 by building/sustaining 6 CVLs for half the cost if not more of 3 CVNs.

One built to commercial standards with steels that don't particularly like heat or blast. Or fragments.I suggest that for all the "studies" we now have two recent full size CV designs, Ford and QE. Costs being about $13bn vs. $4bn. Operational A/C capacity of 70 vs 50. Base ship operating crew 2600 vs 800. Displacement 100k tons vs 70k tons. Speed 32kt vs 29kt. Range unlimited vs 10,000nm (but escorts, aviation fuel etc is limiting for both!)

All above numbers are only ballpark figures (much debate could be had!!!)

One built to commercial standards with steels that don't particularly like heat or blast. Or fragments.I suggest that for all the "studies" we now have two recent full size CV designs, Ford and QE. Costs being about $13bn vs. $4bn. Operational A/C capacity of 70 vs 50. Base ship operating crew 2600 vs 800. Displacement 100k tons vs 70k tons. Speed 32kt vs 29kt. Range unlimited vs 10,000nm (but escorts, aviation fuel etc is limiting for both!)

All above numbers are only ballpark figures (much debate could be had!!!)

If you use NAVSEA's carrier cost per ton metric (biased by HSLA 115/65 use) you end up witha QE hull cost (alone) of ~ $6 billion.

So two CV LXs (LHA-6 mods described above) look far more compelling given the typical k-smaller carriers > bigger carrier argument.

One built to commercial standards with steels that don't particularly like heat or blast. Or fragments.

https://www.tandfonline.com/doi/abs/10.1179/0301923315Z.000000000411?src=recsys&journalCode=yirs20One built to commercial standards with steels that don't particularly like heat or blast. Or fragments.

Evidence for this statement re: CVF UK?

From what I’ve read and heard, a lot of effort went into QE’s survivability, eg. in terms of internal arrangements against flooding or torpedo attacks, magazine and hangar deck protection, distributed propulsion spaces etc.

None of which is relevant since I'm using the same NAVSEA cost per ton metric for CVN-78 for the notional competitors.One built to commercial standards with steels that don't particularly like heat or blast. Or fragments.I suggest that for all the "studies" we now have two recent full size CV designs, Ford and QE. Costs being about $13bn vs. $4bn. Operational A/C capacity of 70 vs 50. Base ship operating crew 2600 vs 800. Displacement 100k tons vs 70k tons. Speed 32kt vs 29kt. Range unlimited vs 10,000nm (but escorts, aviation fuel etc is limiting for both!)

All above numbers are only ballpark figures (much debate could be had!!!)

If you use NAVSEA's carrier cost per ton metric (biased by HSLA 115/65 use) you end up witha QE hull cost (alone) of ~ $6 billion.

So two CV LXs (LHA-6 mods described above) look far more compelling given the typical k-smaller carriers > bigger carrier argument.

The Navy quoted $4.1 billion as cost of new build replacement of the ~40,000t LHD-6 with with its aluminium superstructure, which once again demonstrated how aluminium unsuitable for use in warships with the Bonhomme Richard fire (Ticos also have aluminium superstructures which also resulted in 3,000+ cracks, Navy said the wrong type of aluminium was used).

So would not think new CVL based on a LHA-6 hull would be a good pick due to its relatively low displacement and aluminium superstructure.

Now we just need to find those opponents content to mission kill HVTs.Presumably a mission kill is easier to accomplish and much more practical on ships of this size?

Why would you use the flawed Ford metric of cost per ton for cost of the CVL, Ford is way, way over budget, even the pork barrel politicians in Congress lost patience with the Navy who kept on asking for more and more money for Ford, Congress imposed the oft quoted $13 billion cost cap in 2008$, CBO says that's $16.2 billion in 2019$. Ford was commissioned in July 2017 and build still not complete, Ingalls has 200 shipyard workers currently on board ship installing the weapons elevators, due to complete next April, 3 years and 9 months after commissioning. To work around the Congress cost cap as Ford costs continued to increase the Navy creatively created a 'Phase 2' build for the mission equipment which GAO estimated at additional half billion$ and cut costs by not installing the equipment to allow Ford and Kennedy to operate the F-35Cs. When Congress found out they were understandably upset and insisted Kennedy must have equipment fitted so as to be able operate the F-35C, Navy complained it would be expensive as Kennedy too far into build, Congress overruled the Navy by insisting the Kennedy be equipped to operate the F-35C, too late to fit Ford.None of which is relevant since I'm using the same NAVSEA cost per ton metric for CVN-78 for the notional competitors.One built to commercial standards with steels that don't particularly like heat or blast. Or fragments.I suggest that for all the "studies" we now have two recent full size CV designs, Ford and QE. Costs being about $13bn vs. $4bn. Operational A/C capacity of 70 vs 50. Base ship operating crew 2600 vs 800. Displacement 100k tons vs 70k tons. Speed 32kt vs 29kt. Range unlimited vs 10,000nm (but escorts, aviation fuel etc is limiting for both!)

All above numbers are only ballpark figures (much debate could be had!!!)

If you use NAVSEA's carrier cost per ton metric (biased by HSLA 115/65 use) you end up witha QE hull cost (alone) of ~ $6 billion.

So two CV LXs (LHA-6 mods described above) look far more compelling given the typical k-smaller carriers > bigger carrier argument.

The Navy quoted $4.1 billion as cost of new build replacement of the ~40,000t LHD-6 with with its aluminium superstructure, which once again demonstrated how aluminium unsuitable for use in warships with the Bonhomme Richard fire (Ticos also have aluminium superstructures which also resulted in 3,000+ cracks, Navy said the wrong type of aluminium was used).

So would not think new CVL based on a LHA-6 hull would be a good pick due to its relatively low displacement and aluminium superstructure.

So they'd all have the same HSLA/HY steel bias in the cost metric and the LHA-6 derivative would have an all-steel superstructure.

Because labor/material costs for *hull* construction are based on actuals for CVN-78/79.Why would you use the flawed Ford metric of cost per ton for cost of the CVL,

Hence the extensive use of lightweight steels like HSLA-115/65; they were specifically developed and used on CVN-78 to reduce topside weight andRe CVL based on LHA-6, if LHA-6 superstructure converted from aluminium to all steel would expect the ship stability would be seriously compromised by the additional top weight.

Other thoughts as why not reasonable to base CVL cost using the Ford cost per ton metric, Ford/nuclear ships are expensive.Because labor/material costs for *hull* construction are based on actuals for CVN-78/79.Why would you use the flawed Ford metric of cost per ton for cost of the CVL,

You could argue for some cost improvement curve but since that would scale both notional CVL concepts by the same degree it wouldn't matter.

Hence the extensive use of lightweight steels like HSLA-115/65; they were specifically developed and used on CVN-78 to reduce topside weight andRe CVL based on LHA-6, if LHA-6 superstructure converted from aluminium to all steel would expect the ship stability would be seriously compromised by the additional top weight.

improve CG.

These are strictly hull costs. Not propulsion.Other thoughts as why not reasonable to base CVL cost using the Ford cost per ton metric, Ford/nuclear ships are expensive.

Modern warships do make use of composite armor in those vital places where weight savings are at a premium.If HSLA-115/65 for a CVL/LHD-6 using thin steel plate superstructure would give minimal protection in containing heavy high explosive explsions from warheads on the larger Chinese/Russian anti-ship missiles eg LRASM has a 1000 lbs/450kg warhead, Indian BrahMos Mach 2.8, a/c variant 300 kg/660 lbs warhead.

Surprised the amphibs only 12% cheaper per ton than the CVNs built at NNS with its high overheads driven by nuclear costs, tends to confirm the impression that both BIW and Ingalls yards expensive, the CBO and CRS both expressed incredulity at the Fincantieri costs for the new Constellation frigates based costs per ton compared to Burkes etc. Fincantieri contested the CBO and CRS figures, it has a long history in building cruise ships on time and cost besides warships which have won big export contracts, Fincantieri said warship no more complicated than a cruise ship, time will tell.These are strictly hull costs. Not propulsion.Other thoughts as why not reasonable to base CVL cost using the Ford cost per ton metric, Ford/nuclear ships are expensive.

If you want to use NAVSEA's data (which can be easily reconciled with the budget docs) for amphib hulls cost per ton it's all of 12% cheaper.

i.e CEC would be $5.5 billion (LHA) vs. $6.1 billion (CVN-78/79). That difference per ton is probably more readily explained by CVN-78/79

using more expensive/newer HSLAs that are more labor intensive to weld rather than some nuclear propulsion premium.

Modern warships do make use of composite armor in those vital places where weight savings are at a premium.If HSLA-115/65 for a CVL/LHD-6 using thin steel plate superstructure would give minimal protection in containing heavy high explosive explsions from warheads on the larger Chinese/Russian anti-ship missiles eg LRASM has a 1000 lbs/450kg warhead, Indian BrahMos Mach 2.8, a/c variant 300 kg/660 lbs warhead.

And deckhouses tend to have natural or designed blow-out paths.

Take a look at some of the armor schemes of battleships, and you'll see that the armor only covered so much, and in a certain way, much like a box, because with gun-launched projectiles, you could be fairly sure how they'd approach your ship. There's only certain arcs that needed to be covered.Surprised the amphibs only 12% cheaper per ton than the CVNs built at NNS with its high overheads driven by nuclear costs, tends to confirm the impression that both BIW and Ingalls yards expensive, the CBO and CRS both expressed incredulity at the Fincantieri costs for the new Constellation frigates based costs per ton compared to Burkes etc. Fincantieri contested the CBO and CRS figures, it has a long history in building cruise ships on time and cost besides warships which have won big export contracts, Fincantieri said warship no more complicated than a cruise ship, time will tell.These are strictly hull costs. Not propulsion.Other thoughts as why not reasonable to base CVL cost using the Ford cost per ton metric, Ford/nuclear ships are expensive.

If you want to use NAVSEA's data (which can be easily reconciled with the budget docs) for amphib hulls cost per ton it's all of 12% cheaper.

i.e CEC would be $5.5 billion (LHA) vs. $6.1 billion (CVN-78/79). That difference per ton is probably more readily explained by CVN-78/79

using more expensive/newer HSLAs that are more labor intensive to weld rather than some nuclear propulsion premium.

Modern warships do make use of composite armor in those vital places where weight savings are at a premium.If HSLA-115/65 for a CVL/LHD-6 using thin steel plate superstructure would give minimal protection in containing heavy high explosive explsions from warheads on the larger Chinese/Russian anti-ship missiles eg LRASM has a 1000 lbs/450kg warhead, Indian BrahMos Mach 2.8, a/c variant 300 kg/660 lbs warhead.

And deckhouses tend to have natural or designed blow-out paths.

Steel

If using the newer HSLA steel which saying is a very labor intensive to weld and if not be suitable for robotic welding would not it be a better trade off to use thicker commercial weldable steels eg DH36/EH36 controlled rolled and normalized, heat treated to stress relive the steel to give necessary toughness as used in the UK carriers) understand Far Eastern and European shipyards now able to weld hull with robotic production lines and even mention of spider automatic robots for assembly and welding.

If the CVL limited by LHD-6 design constraints of max weight and then having to use a limited amount of expensive composite armour would expect only able outfit the magazines and CIC, plus thin steel for superstructure expect a 2.8 Mach BrahMos to go thro the thin steel like a hot knife thro butter, never understand why armor is not a much higher priority in navy ships these days, with the warheads on anti-ship missiles equivalent to the big shells of the battleship era. The ships of those days had no thin steel, the aim with thicker armor steel was to contain the explosion so limit the damage to enable ship to carry on fighting.

But those overhead cost wouldn't be reflected in the NAVSEA cost/ton metric. Those costs tend to show up in plan costs and ECO.Surprised the amphibs only 12% cheaper per ton than the CVNs built at NNS with its high overheads driven by nuclear costs, tends to confirm the impression that both BIW and Ingalls yards expensive,

The believed drivers for non-CV/amphib surface combatant costs are outfit density and power density; Constellation is bad on both counts.the CBO and CRS both expressed incredulity at the Fincantieri costs for the new Constellation frigates

Their cost overruns on LCS notwithstanding apparently.Fincantieri contested the CBO and CRS figures, it has a long history in building cruise ships on time and cost

I don't see anything preventing the automation of HSLA welding beyond the fixed-costs of automation.If using the newer HSLA steel which saying is a very labor intensive to weld and if not be suitable for robotic welding would not it be a better trade off to use thicker commercial weldable steels eg DH36/EH36 controlled rolled and normalized, heat treated to stress relive the steel to give necessary toughness as used in the UK carriers) understand Far Eastern and European shipyards now able to weld hull with robotic production lines and even mention of spider automatic robots for assembly and welding.

There weren't really shaped charged threats to battleship armor; ASCMs have huge diameters and you can afford exoticBrahMos to go thro the thin steel like a hot knife thro butter, never understand why armor is not a much higher priority in navy ships these days, with the warheads on anti-ship missiles equivalent to the big shells of the battleship era.

There is also the damage control to think about.here weren't really shaped charged threats to battleship armor; ASCMs have huge diameters and you can afford exotic

reactive material liners for multi-stage shaped charge/follow-through warheads that will punch large diameter, long length holes into

BB armor so that the follow-though charge can detonate in the interior.

In theory, the modern insensitive rocket motors aren't supposed to detonate when hit with a shaped charge jet.Then you what the Zumwalt has, basically use you weapons as armor. The Zumwalt MK57 P-VLS is design to explode out if it takes a hit, this will cause it to act very much like a ERA plate to missiles. Add in the massive charge of most missiles compare to ERA means it will basically destroy the missile before it has a chance to fire a second stage weapon. Then you have the Electric Armor that is basically like ERA but instead of high explosives you have a very high electrical charge between two plates with a thick insulator between them. When a weapon pierces it arcs violently destroying the penerator before it has a chance to react. Of course both ways are new which mean unproven and very expansive.