Please pardon the absolutely

huge number of quotes, I binged the entire thread over the last ~36 hours.

The Army names them after Indian tribes. Since FVL medium is years and years away, I doubt if anyone's even thought of that. Interestingly enough, the USN has six ships presently in service named after North American Indians or tribes, both "friendly" and "hostile". They have been a number of ships over the years so named and Chief Tecumseh (who always fought the US) was honored with having four named after him, including an SSBN.

Tecumseh was also well enough thought of shortly after the time of his death that William Tecumseh Sherman was named for him.

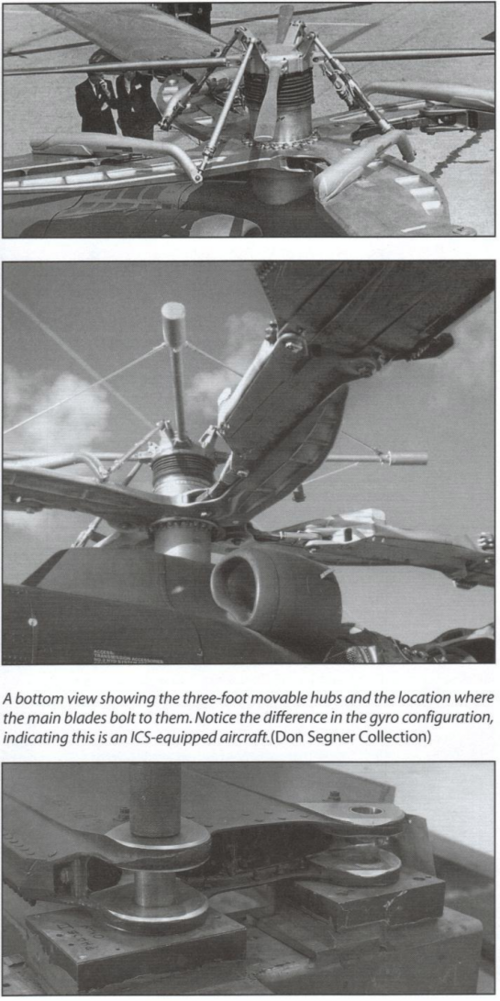

This illustrates the question I'm asking: prior to 2010 or so, X2 depictions showed the engines/mast in the same location as in a conventional helo. Since then, they're showing the mast assembly moved aft. Any particular reason? Pre-2010 concepts below (they're elsewhere on the forum, I just repeated 'em here for convenience).

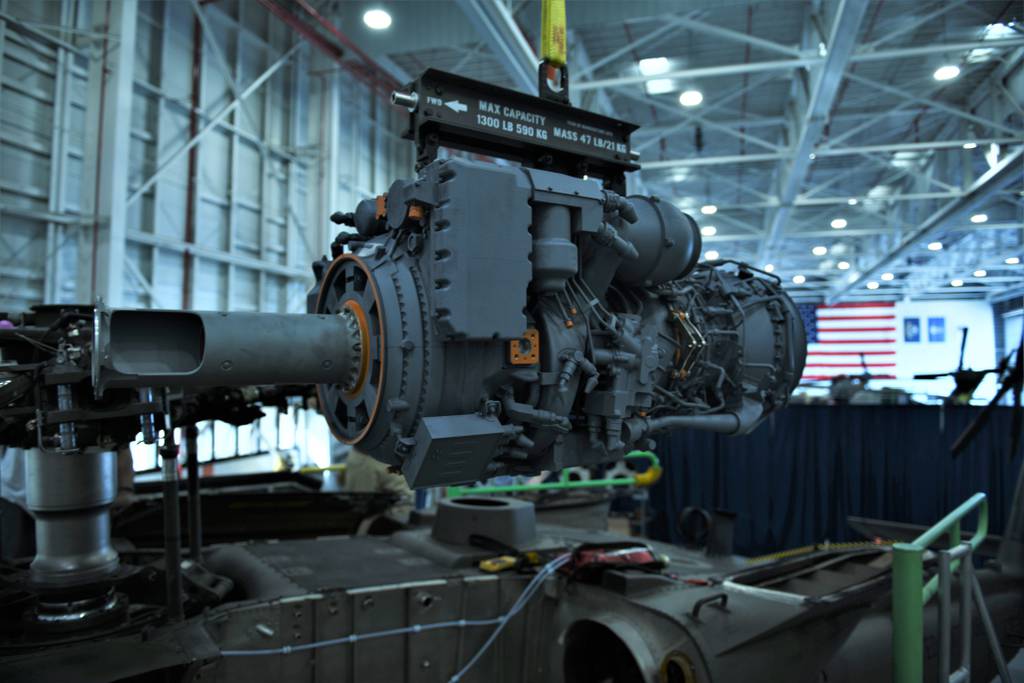

I believe because of how huge the transmission ended up being.

We will all be pushing up daisies before the Blackhawk leaves the fleet.

And when the last Blackhawk is flown into the Boneyard, the crew will be flown back out in a Huey!

The alternative being what, exactly? There isn't anything else even vaguely plausible for the same role.

There is also the question of whether the United States Navy, United States Marine Corps, and the United States Air Force are also going to join JMR-Medium to replace their Bell UH-1 Huey, Sikorsky SH-60 Sea Hawk, and Sikorsky MH-60 Black Hawk helicopters. In addition, are Defiant and Valor too large for use on United States Navy cruisers and destroyers or can they be partially dismantled to fit the dimensions of the hangers on these ships.

USN needs something that is good at the hover. I suspect it's going to be a King Seahawk, something with T901 engines that sorta looks like an H60, but doesn't share many parts with one. It's also gotta fit into existing hangars, so it's not going to be much taller than an H60.

USMC wants something that can keep up with the Osprey, which by definition means a Tilt Rotor for both Huey and Cobra replacements. V-280 variants may work, or it may take something different.

USAF CSAR will happily buy some V-280s with an inflight refueling probe.

Btw, the latest pics of the tech demonstrator's proprotors suggest that they are borrowed from the Osprey

Regards, Michael

Might as well. The hubs are the complex part and we all know the Osprey hubs are solid. Blades may or may not be the same, but they're easy to swap out.

Dont get me wrong Commanche like performance and carrying as few as two scouts/pax would be game changer but a jet CAS needs to come from somewhere.

There are two separate "CAS" roles. One is the dance at the FEBA, where the A-10 plays. The other one is battlefield interdiction, and that's where the A-7s worked, as well as where the F-35s will work.

I keep wondering when they're going to get rid of swashplates.

And replace them with what?

The Marines want AURA to not only keep up with the 275-kt. MV-22 but be able to get to the landing zone ahead of the Ospreys to provide defensive support, or to divert en route to deal with an objective before catching up with the tiltrotors.

Designed for a 280-kt. cruise speed, Bell’s V-280 has exceeded 300 kt. in tests. The SB-1 is designed for at least 250 kt. but could go faster with more power. The upper limit is “certainly [faster than] 250 kt., and it is certainly less than 400,” says Randy Rotte, Boeing’s vice president of business development for FVL. “It is not so much what the configuration can do; it is how much power I put in there.”

Advantage definitely seems to be with the V280 here. Particularly the range requirements!

It gives significant increase in strategic flexibility to the US Army. To bad they don't have had C-130 with refuel capability.

That's easy, the KC-130s use buddy tanks. I'm sure there's already a few "accidentally ordered the wrong NSN" hiding back in some CONEX box...

That's a good looking Bell helo, but why the single engine? Is it an Army requirement? I'm sure there's going to be a need for a Cobra replacement in the future as well, and the Marines like their twin engines.

Marines want something fast enough to escort the Ospreys. They're not interested in the "slow" FARA offerings.

And Boeing with an interesting quote:

Whatever their aircraft is like, Boeing's PR strategy is definitely stealthy. There's a strategic reason for that.

breakingdefense.com

Ah, Open Source Industrial Intelligence.

Not to mention the military promotions depending on getting the choice right. I really like the SB-1 more for the Army's mission (More hovering, versus transit) and the V-280 for special mission and Marine/Navy missions. But, given how well the V-280 has performed, it's been virtually bulletproof, and all of the development issues with the SB-1, I have to say that I would choose the V-280 if I had to make the decision right now.

Navy spends most of their time hovering, and needs something that fits in their hangars. Marines might want V-280s.

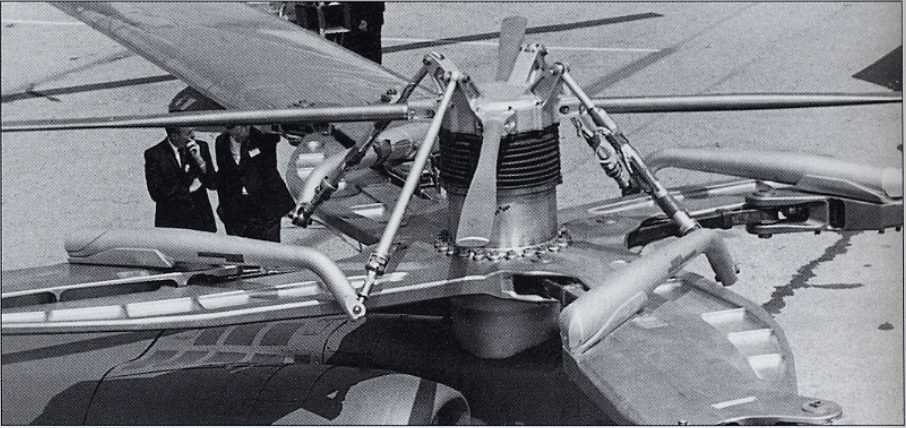

Is that a Pusher and a anti-torque tailrotor?

Yup. Old school Cheyenne style!

Flying as a pure aeroplane is superior to rotation based lift. Unloading eliminated all retreating stall better lift. No vibration.. Symetric lift phenomenon.

Wind tunnel testing and full scale flight testing showed that rotor drag was minimized when the wings took 80% of the total lift.

Without disagreeing in the slightest with the point on folded/hangar size, there's also the issue of maintaining them on austere forward operating locations and how you manage to do any needed work on the SB>1's rotors/rotor hub - stepladder on top of a HMMWV?

That, and stepladder on top of the doghouse for the hub.

They should pitch it as a Viking replacement too. We're going to need those.

Could just pull them out of the Boneyard, they only have about half their lifespan used up.

Speed does not buy its was into the equation if you are not routinely operating at 100 miles or more. So the only place rotorcraft with much greater speed are potentially viable would be deep sea oil I think. Possibly specialised medical.

Life flight medevac strikes me as THE civilian side use case for fast helicopters.

It would be nice to have a clue how many sortie Russian helicopters are flying on a regular bases. If they are losing a helicopter for every ten sortie, that is bad. Losing one every one hundred sortie, against a well equipped and TRAINED enemy may be normal in modern war. I suspect that, like many other challenges for the aircrew, they were lucky to get ten hours of training a month, most of which was very prescriptive flights. This makes something like night combat operations impossible for them.

What was the loss rate for Hueys in Vietnam?

Of course, then the next question is, if CMV-22B is so good, why not buy more of those for the portion of the Sierra mission that tiltrotor works for (logistics, SAR/CSAR, NSW support, I'm guessing) and converge the other parts back with the Romeo replacement.

That may be a useful option, though I don't think you can stuff an Osprey into a DDG hangar. The question is how many DDGs, etc are cruising around with 1x Sierra and 1x Romeo.

Thinking more about the Italian General's comments. If the V-280 version of FLRAA goes into production there will be competion within the military and para-military market against the AW-609. While I think there would still be a market for 609, it would be reduced by another tilt rotor platform. Not happy news for one of Italy and Europes primary MIC.

When Bell sold off the 609, they included a clause that it CANNOT be used for military contracts.

The hangar size constraint seems like a tough one - and it explains the Navy's significant lack of interest in FVL. If you are doing a DDG redesign, do you build in margin for the future? As it is, the V-22 was notoriously constrained in rotor size due to the need to fit on a LHA that it only overlapped in service for about 2 years.

Now that those LHAs are out of the picture, could we add a couple of feet to the Osprey proprotors?

If they already felt rigid coax didn't work they could have specifically forbidden it from the competition at the outset.

This would have required them to know that the rigid coax didn't work when they set up the terms of the competition.

I have to wonder if the folks at Kamov rolled their eyes or tried not to "snort tea" giggling when they first heard of the revival of the ABC system in the US.

It will be interesting in the coming years to see what direction Sikorsky goes with advanced rotorcraft if Raider is not selected. They did extensive work in the past with tilt wing technology and variable diameter rotor systems.

tovarisch, vodka

burns when you snort it out your nose!