"Fuel-Efficient Engine to Increase Range, Power of Army Helicopters"

January 2014

by Valerie Insinna

Source:

http://www.nationaldefensemagazine.org/archive/2014/January/Pages/Fuel-EfficientEnginetoIncreaseRange,PowerofArmyHelicopters.aspx

January 2014

by Valerie Insinna

Source:

http://www.nationaldefensemagazine.org/archive/2014/January/Pages/Fuel-EfficientEnginetoIncreaseRange,PowerofArmyHelicopters.aspx

During the Iraq and Afghanistan wars, Black Hawk helicopters were regularly flown at higher altitudes and in hotter temperatures than their engines were designed to withstand. With underpowered engines in those conditions, each helicopter could only carry five soldiers at a time — about half of an 11-person squad.

The Army over the next decade plans to phase out legacy equipment and introduce a new, more powerful engine that will be able to take a full squad twice as far, all while burning less fuel. Through the Improved Turbine Engine Program, or ITEP, the service will replace the T700 engines that power its Black Hawk and Apache helicopters.

When the Army fielded General Electric’s T700 engine in the 1970s, it required that an engine be able to transport a squad at 4,000 feet in 95-degree Fahrenheit temperatures.

“What they’ve learned through Iraq and Afghanistan, but also in other theaters, is that’s not sufficient to cover the globe,” said Jerry Wheeler, vice president of the Advanced Turbine Engine Co. (ATEC), a joint venture between Honeywell and Pratt & Whitney.

ATEC is one of the participants in an Army Aviation Applied Technology Directorate initiative called the Advanced Affordable Turbine Engine program, a science and technology effort that is a precursor to the improved turbine engine program of record.

No engine will be fielded at the conclusion of the AATE program, but it has given ATEC and General Electric a head start in developing the technologies the Army will need for its future engine. The ITEP competition is slated to begin this year, as the science and technology program comes to a close.

The goal of the AATE program is to develop a 3,000-shaft horsepower engine around the same size as the T700, which weighs about 450 pounds. The engines will be 50 percent more powerful and 25 percent more fuel-efficient. The new engines also will have a longer lifespan and lower maintenance costs.

The requirements for the improved turbine engine have not been finalized, but the AATE program is designed to help reduce the risk of developmental technologies that will likely be pulled into the ITEP program, said Gary Butler, engine systems team leader at the Aviation Applied Technology Directorate.

“We’re providing a technology foundation to achieve the better fuel efficiency metrics and better horsepower to weight to get … more power in that same envelope,” he said.

With the ITEP engine, commanders will not have to choose between fielding a high-powered engine and saving money on fuel, said Lt. Col. Roger Kuykendall, Army program manager of common engines.

“ITEP is the best of both worlds,” he said.

The engine will expand the helicopter’s flight ceiling to meet the Army’s new requirement — an altitude of 6,000 feet in 95-degree weather, he said.

Black Hawk and Apache helicopters can fly in those conditions now, he said. But with the new engine, a Black Hawk’s range and the number of troops it can carry will double.

The Black Hawk is the Army’s most versatile aircraft and is able to accomplish missions ranging from transporting troops to conducting air assaults. Today, when an 11-person squad is assigned to carry out a mission 150 miles away, two Black Hawks are needed to transport the troops, and the aircraft would have to stop halfway through the flight to refuel and pick up ammunition, Kuykendall said.

Doing that requires more personnel and more convoys on the road that are subject to improvised explosive devices, thus increasing risk to troops and equipment, he said.

In order to carry a full squad, commanders could use a CH-47 Chinook heavy lift helicopter, which burns more fuel, Wheeler said. Neither option is ideal.

The Apache would be able to loiter significantly longer if equipped with an ITEP engine, Kuykendall said. “If you did it with a current engine, maybe you can’t take all your ammo with you or all your rockets. You have got to cut down ammunition and add more fuel. So now they can stay on [station] longer with the full complement of their weapons.”

As part of an analysis of alternatives, the Army has studied how long loiter time would be increased with an ITEP engine. Because the analysis isn’t due until the end of January, Kuykendall could not offer specific data.

The engines would cut fuel consumption and therefore cost, an enticing prospect during a period of fiscal austerity. Using data from the past five years, the service estimates the engines will save 14 million gallons of fuel a year if flying hours remain the same, he said.

The Army plans to release a request for proposals for the ITEP engine by the end of spring. Competitors would progress through a technology development phase ending in fiscal year 2019, followed by an engineering-and-manufacturing development phase. Low-rate initial production would start after a Milestone C decision scheduled for 2023.

Although the service wants to retain two contractors through EMD, which would include testing the engine and integrating it with aircraft, “unfortunately I don’t think the funding is there to do that,” Kuykendall said. Because of budget pressures on the program, the service may be forced to downselect to a single vendor earlier in the competition, he said.

Supporting multiple vendors through a competition is expensive, said a government worker who is affiliated with the program but is not allowed to speak to reporters. However, having contractors compete with each other though a longer span of development may help to drive down cost and risk for the Army, resulting in a better product.

“It has a lot of general officer [support]. We understand the importance of it and the cost savings we can get from it. It’s just unfortunate that with the fiscal constraints that the Army is under right now, some hard choices have to be made,” he said.

The service will ultimately purchase 6,215 engines, 10 percent of which are spares, to replace those in the Black Hawk and Apache, Kuykendall said.

It may buy even more ITEP engines for the Army’s next-generation family of rotorcraft, called future vertical lift. The Army plans on fielding light, medium, heavy and ultra-heavy versions of the aircraft, officials have said. Initial operational capability is planned for 2034.

The Army will likely install the engine in at least some of the variants, but because requirements for future vertical lift are still in the works, Army officials have yet to decide which versions will incorporate the engine.

The hope is that engines will at least be installed in the light and medium aircraft, Wheeler said.

Kuykendall is working with other Army officials to mesh production timelines so that the future vertical lift program can incorporate the ITEP engine into its development. The service wants to avoid a repeat of the failed Comanche program, which sought to build an advanced attack helicopter and its engine at the same time. Every time a requirement changed for one program, the other would have to make adjustments, Kuykendall said.

“What I would like to do is to get an ITEP production model done during the future vertical lift tech development phase,” he said. If the Army’s program executive office for aviation decides to use the new engines in those aircraft, “it reduces [its] risk. They’ll have an engine to plan around.”

PEO aviation has upgraded the T700 every decade since its introduction and is currently replacing its 701-Cs with D-models. But for the most part, the 40-year-old engine’s design has peaked, Kuykendall said.

“If you wanted to squeeze something else out of this engine, you’re only going to get maybe an extra 100 shaft horsepower, maybe one or two improvements to fuel efficiency,” he said.

After five years of design and development, the Advanced Affordable Turbine Engine program is winding down. Both ATEC and General Electric have built and demonstrated two engines, Butler said.

Incumbent General Electric is offering the GE3000, a 3,000 horsepower engine that weighs roughly the same as the T700. General Electric officials did not respond to requests for comment.

The GE3000 sports new materials and cooling configurations and a more aerodynamic design than its predecessor, the company website said.

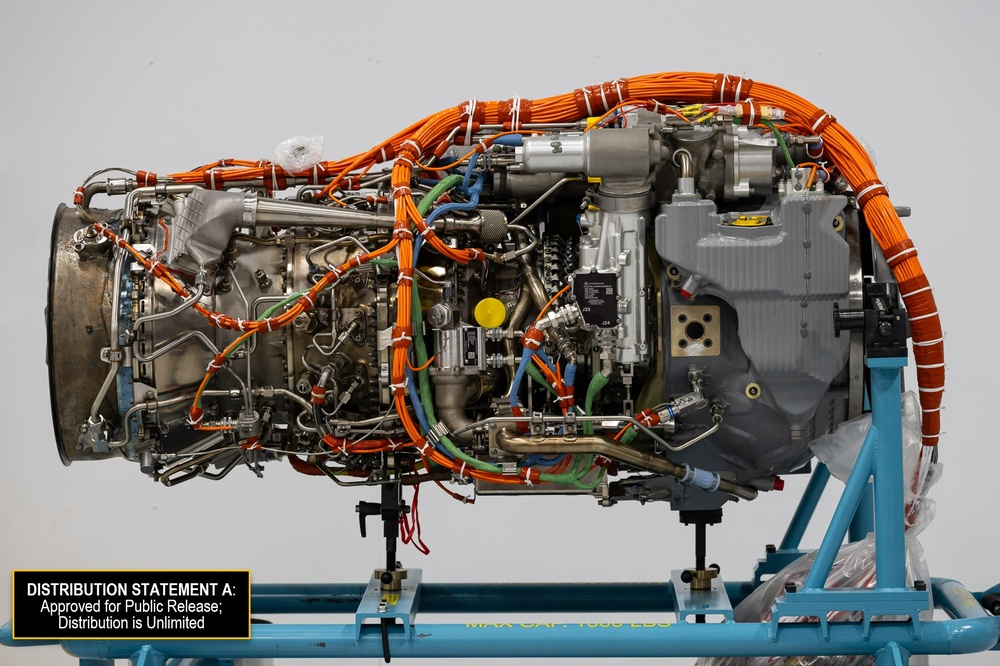

ATEC has developed the HPW 3000, which officials said would secure a 25 percent improvement in fuel efficiency, saving 50 million gallons a year.

It would lower production and maintenance costs by at least 20 percent and save $4.5 million in maintenance costs, according to company materials. When combining savings from fuel efficiency, maintenance and logistics, ATEC estimates its engine will cut total costs by $1 billion compared to the legacy T700.

Besides those savings, the HPW 3000 gives Apaches at least an extra 48 minutes of loiter time and a 3,330 increase in lift capacity, allowing the aircraft to carry a full load of fuel and weapons, the company said. It would also double the Black Hawk’s range and payload.

Wheeler would not say whether Apache or Black Hawk airframes would need to be modified in order to accommodate the engine. “Our goal since day one in configuring the engine was to pursue a drop-in capability,” he said.

The first engine completed durability tests in July, and the company was pleased with the results, Wheeler said. “It validated that the program’s goals are within reach.”

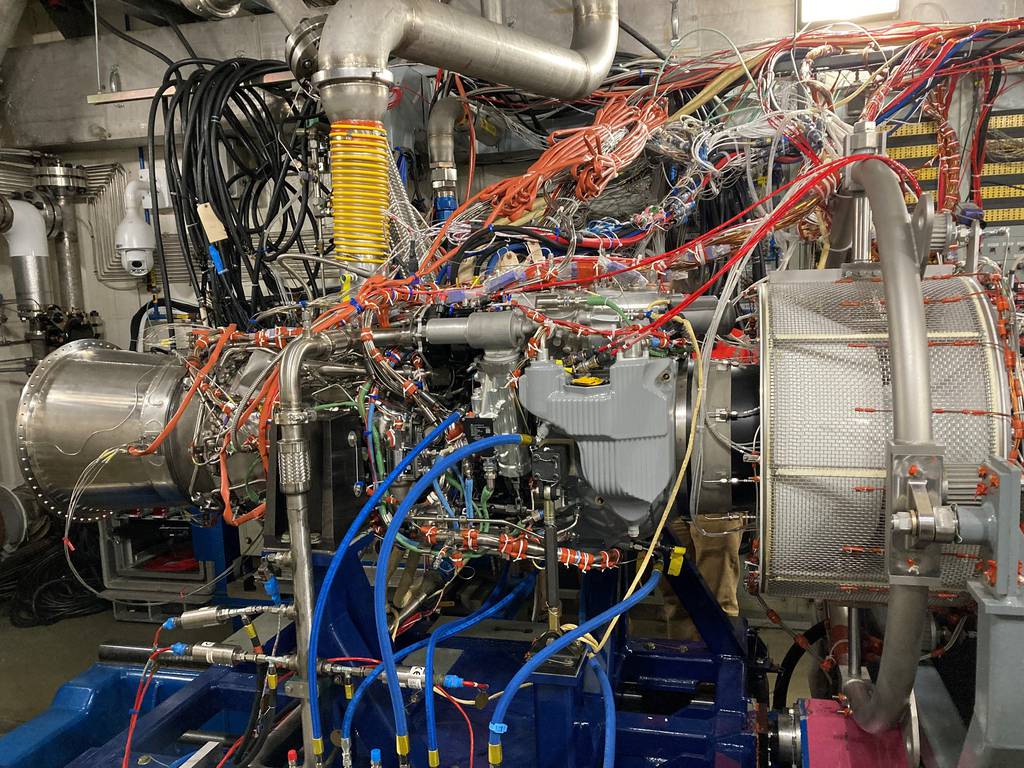

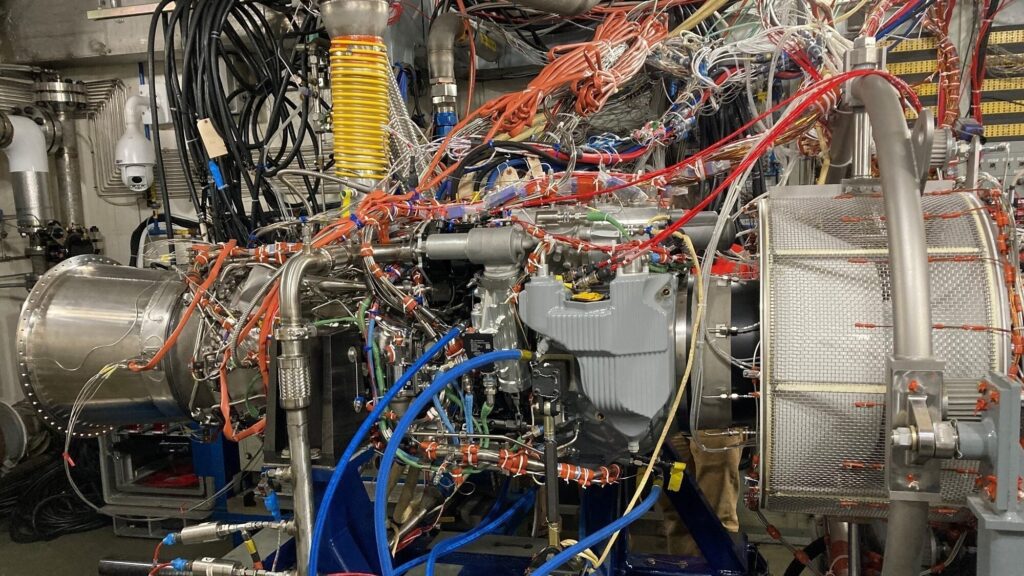

The second engine began performance tests in September, and will move on to sand ingestion tests after that, he said.

During performance tests, technicians collect data on each of the engine’s components, such as how they respond to high pressure and hot temperatures, Butler said. They also measure horsepower and fuel efficiency to ensure the engine is meeting program goals.

For sand ingestion tests, “we actually have a rig set up to throw sand into the engine and measure the capability of that engine to tolerate that sand ingestion,” he said. “That’s usually not a typical test we do in S&T, but we thought that would be a good demonstration vehicle” to drive down risk before the ITEP program of record begins.