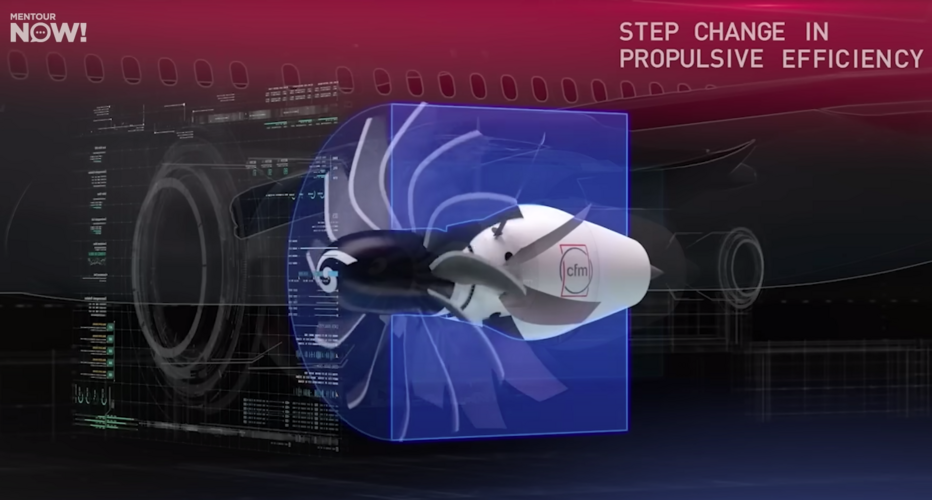

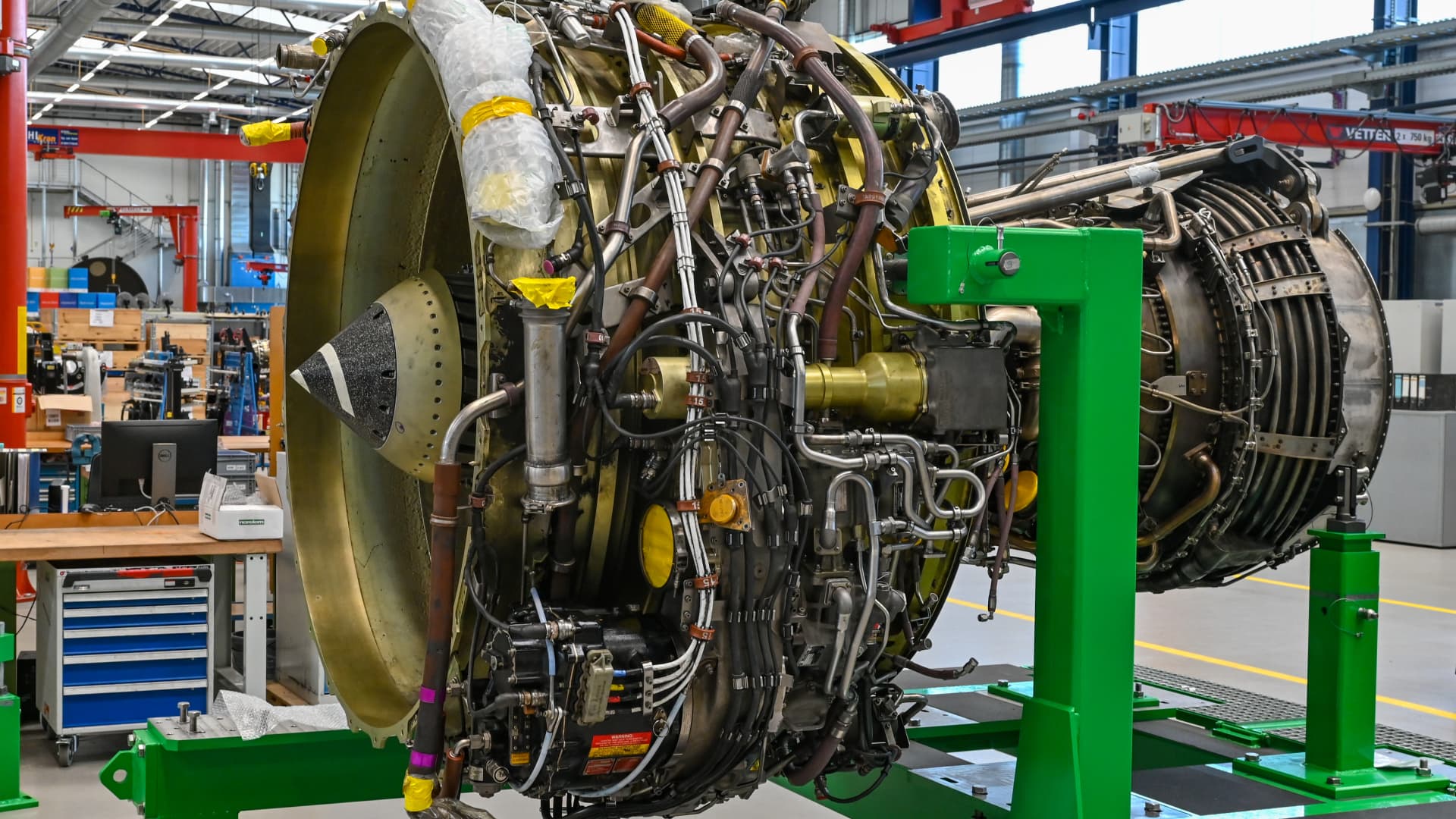

GE Aviation and France's Safran together produce some of the most commonly used aircraft engines under their CFM joint venture. Together they launched a new program, called CFM Rise, that will develop and test new technology that could enter service in the mid-2030s, the companies said.

[...]

The RISE program will work on technology that could reduce fuel consumption by more than 20% and also be compatible with sustainable aviation fuel and hydrogen, they said.

The companies plan to design an engine that is open fan, which is unlike the covered jet-engines on commercial aircraft.

GE, Safran developing cleaner energy aircraft engines that could work with hybrid technology, hydrogen

General Electric's aviation unit and joint venture partner Safran plan to develop new aircraft engines that would require more than 20% less fuel.

Last edited: