Grey Havoc said:

Just a thought; rather than be of alloy, could those pieces be made of a wood such as Sitka spruce, but resin impregnated?

Judging the construction and what it was intended to be, I'm pretty sure, that it was made from wood.

Would an impregnation with resin have been feasible for an amateur constructor back then ?

Another photo shows a guy bending a sheet of material, that may have been used for covering the wing.

Seems to be relatively soft, so stiffening it may not have been a bad idea ?

Brought me to the idea, that those ribs and half ribs visible on the leading edge probably doesn't

represent the ribs itself, but perhaps are covering the fixtures of the planking to those ribs. Glue and nails

are mentioned in Janes 1947 for the fuselage, would it be plausible for the wing, too ?

cluttonfred said:

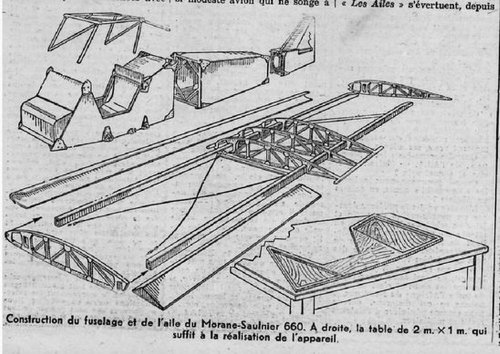

..I do admire the spirit of the MS.660: imagine a major aviation company today offering kits for amateur construction on the kitchen table?

The idea of building an aircraft on a kitchen table, was somehow politically influenced, I think, as the basic

idea behind this aircraft probably was similar to that of the "concours de l'aéronef de grande vulgarisation"

(competition for an aircraft of wide propagation) somewhat later. Flying should become a hobby for

common people, so that in the event of an national emergency a big cadre of trained pilots would have

been available.