- Joined

- 25 June 2009

- Messages

- 13,777

- Reaction score

- 3,046

The 329Amphibian: an ambitious project

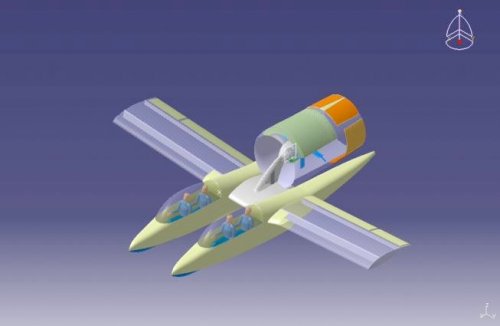

Self-proclaimed as "the world's most advanced amphibious airplane", Leader Industries' catamaran hulled seaplane was initially known as the 329Amphibian. Aimed at providing the sportsman or the military "a unique advantage over any other seaplane manufacturer", the "329" was a unique twin-hull amphibian aircraft design with a huge ducted fan mounted on top that resembled no other aircraft. It could be used by the sportsman, commuter, and the Navy Seals and still meet the unique criteria for their respective needs. The desire to create this plane came from a knowledge of what was currently available in the general aviation market place, including kit planes and what the company knew was possible with today's engineering. That is why the design, registered under U.S. Patent # 6,592,073 B1, consciously incorporated many of the best features from established amphibians such as the Renegade, Seawolf, Seawind, Sea Fury, SeaBee, and several kitplane flying boat designs.

The project was publicized in 2002, when newcomer Leader Industries sought funding for the creation of the "329" aircraft. Leader aimed to respond to NASA's Small Business Innovation Research (SBIR) in an effort to achieve engineering capital for the project. It ambitioned to realize prototype construction and production of the aircraft at an efficient and effective pace, and was willing to joint venture with or share rights with members of the aircraft industry who had production capabilities. For this purpose, the company made initial overtures to qualified parties for testing/engineering of this aircraft.

An unusual but promising configuration

Two models of the 329Amphibian were built in 2003: One as a static display to show the uniqueness of the design, and a radio-controlled flying model as proof of concept. The Sea trials from the models proved the design to be as expected, and demonstrated the great look down capability of the design, since the wings, being located well aft of the cockpit, allowed for downward visibility usually only associated with high wing aircraft.

The catamaran twin hulls were seen as the key to the performance of the 329Amphibian. Not only this unique configuration was meant to offer stability and reduced drag, but it provided better balance both in the water and in the air. The twin ellipsoidal hulls allowed the aircraft to hydroplane while landing, taxiing or departing, making for maximum control during water operations. The elliptical hulls allowed the plane to better travel on water and to be more efficient in the air. Beaching or docking the plane was facilitated by the wing section between the hulls, and the landing gear was faired into the catamaran hulls, protruding enough for airport landings without adding significant drag. As for the "Ring Airfoil", it provided vectored thrust offering propulsion efficiencies while stabilizing both laterally and longitudinally. The back of the ducted fan would house control surfaces. Thrust was controlled and quieted by the ducted fan, and because the propeller was encapsulated in a ring airfoil, prop noise was significantly attenuated, allowing urban operations.

Initial collaboration with Embry-Riddle

In 2004, Leader Industries contracted with Embry-Riddle Aeronautical University, which remained on the cutting edge of many new aeronautic technologies. Leader sought to use their expertise in the prototype construction, and they requested that Embry-Riddle accomplish a preliminary design of the 329Amphibian concept to include: preliminary weight estimate; wing design; fuselage layout, including buoyancy of hull shape; engine selection and installation as may be integrated with the ducted fan patents; structural concept; weight and balance; stability and control analysis; static performance (level flight speed, climb performance, takeoff distance); cost estimation; physical configuration; and documentation via CATIA solid model drawings. The preliminary engineering evaluation by Embry-Riddle Aerospace Engineering and Research Center, originally due in September was completed after being delayed by at least three hurricanes. The report revealed that the aircraft embodied everything that had been hoped for and more.

The choice of Embry-Riddle proved to be an auspicious one as they had prior involvement in ducted fans and associated control surfaces. As data was available they were able to expedite analysis. New data placed the maximum speed for the new amphibian at 186 knots (218 mph) and the cruise speed at 160 knots (185 mph). Performance would be improved with the incorporation of composite construction as opposed to the heavier fiberglass material used in the analysis. Additional efficiency and speed increases should result by adapting the rotary engine being developed by Embry-Riddle. It was expected that by refining the design further, it would be possible to reduce drag and improve the aesthetics of the aircraft. A software cost analysis performed by Embry-Riddle, concurrent with the engineering evaluation, showed the new amphibian to be highly competitive due to simplicity of design. Accordingly, a change to composite material was warranted and would leave Leader Industries in a competitive marketing posture.

Leader planned partnership with Embry-Riddle toward development of the prototype amphibian aircraft while working toward funding the full-scale development project in the interim interval. Initial contact was made with some undisclosed which had expressed interest in funding the new amphibian, a group already involved in funding another prototype aircraft.

In 2006, the provided figures for the 329Amphibian were as follows:

- Length: 17.91 ft

- Span: 33.6 ft

- Weight (GTOW): 3524.7 lb

- Weight (empty): 2125.01 lb

- Fan: 4-Blade, 6-inch chord, 5-foot diameter prop.

The pitch angle was set at an angle such that the prop would absorb 210 hp or 70% power at 200 mph in the forward direction.

Self-proclaimed as "the world's most advanced amphibious airplane", Leader Industries' catamaran hulled seaplane was initially known as the 329Amphibian. Aimed at providing the sportsman or the military "a unique advantage over any other seaplane manufacturer", the "329" was a unique twin-hull amphibian aircraft design with a huge ducted fan mounted on top that resembled no other aircraft. It could be used by the sportsman, commuter, and the Navy Seals and still meet the unique criteria for their respective needs. The desire to create this plane came from a knowledge of what was currently available in the general aviation market place, including kit planes and what the company knew was possible with today's engineering. That is why the design, registered under U.S. Patent # 6,592,073 B1, consciously incorporated many of the best features from established amphibians such as the Renegade, Seawolf, Seawind, Sea Fury, SeaBee, and several kitplane flying boat designs.

The project was publicized in 2002, when newcomer Leader Industries sought funding for the creation of the "329" aircraft. Leader aimed to respond to NASA's Small Business Innovation Research (SBIR) in an effort to achieve engineering capital for the project. It ambitioned to realize prototype construction and production of the aircraft at an efficient and effective pace, and was willing to joint venture with or share rights with members of the aircraft industry who had production capabilities. For this purpose, the company made initial overtures to qualified parties for testing/engineering of this aircraft.

An unusual but promising configuration

Two models of the 329Amphibian were built in 2003: One as a static display to show the uniqueness of the design, and a radio-controlled flying model as proof of concept. The Sea trials from the models proved the design to be as expected, and demonstrated the great look down capability of the design, since the wings, being located well aft of the cockpit, allowed for downward visibility usually only associated with high wing aircraft.

The catamaran twin hulls were seen as the key to the performance of the 329Amphibian. Not only this unique configuration was meant to offer stability and reduced drag, but it provided better balance both in the water and in the air. The twin ellipsoidal hulls allowed the aircraft to hydroplane while landing, taxiing or departing, making for maximum control during water operations. The elliptical hulls allowed the plane to better travel on water and to be more efficient in the air. Beaching or docking the plane was facilitated by the wing section between the hulls, and the landing gear was faired into the catamaran hulls, protruding enough for airport landings without adding significant drag. As for the "Ring Airfoil", it provided vectored thrust offering propulsion efficiencies while stabilizing both laterally and longitudinally. The back of the ducted fan would house control surfaces. Thrust was controlled and quieted by the ducted fan, and because the propeller was encapsulated in a ring airfoil, prop noise was significantly attenuated, allowing urban operations.

Initial collaboration with Embry-Riddle

In 2004, Leader Industries contracted with Embry-Riddle Aeronautical University, which remained on the cutting edge of many new aeronautic technologies. Leader sought to use their expertise in the prototype construction, and they requested that Embry-Riddle accomplish a preliminary design of the 329Amphibian concept to include: preliminary weight estimate; wing design; fuselage layout, including buoyancy of hull shape; engine selection and installation as may be integrated with the ducted fan patents; structural concept; weight and balance; stability and control analysis; static performance (level flight speed, climb performance, takeoff distance); cost estimation; physical configuration; and documentation via CATIA solid model drawings. The preliminary engineering evaluation by Embry-Riddle Aerospace Engineering and Research Center, originally due in September was completed after being delayed by at least three hurricanes. The report revealed that the aircraft embodied everything that had been hoped for and more.

The choice of Embry-Riddle proved to be an auspicious one as they had prior involvement in ducted fans and associated control surfaces. As data was available they were able to expedite analysis. New data placed the maximum speed for the new amphibian at 186 knots (218 mph) and the cruise speed at 160 knots (185 mph). Performance would be improved with the incorporation of composite construction as opposed to the heavier fiberglass material used in the analysis. Additional efficiency and speed increases should result by adapting the rotary engine being developed by Embry-Riddle. It was expected that by refining the design further, it would be possible to reduce drag and improve the aesthetics of the aircraft. A software cost analysis performed by Embry-Riddle, concurrent with the engineering evaluation, showed the new amphibian to be highly competitive due to simplicity of design. Accordingly, a change to composite material was warranted and would leave Leader Industries in a competitive marketing posture.

Leader planned partnership with Embry-Riddle toward development of the prototype amphibian aircraft while working toward funding the full-scale development project in the interim interval. Initial contact was made with some undisclosed which had expressed interest in funding the new amphibian, a group already involved in funding another prototype aircraft.

In 2006, the provided figures for the 329Amphibian were as follows:

- Length: 17.91 ft

- Span: 33.6 ft

- Weight (GTOW): 3524.7 lb

- Weight (empty): 2125.01 lb

- Fan: 4-Blade, 6-inch chord, 5-foot diameter prop.

The pitch angle was set at an angle such that the prop would absorb 210 hp or 70% power at 200 mph in the forward direction.