You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Boeing 787 Dreamliner

- Thread starter Sundog

- Start date

Bill Walker

Per Ardua ad Nauseum

I can only suggest it was some mode nobody thought of. Perhaps a failure mode, perhaps some combination of production tolerances on individual cells. In any case, one cell got hot, probably due to excessive current draw, driving it in to thermal runaway. This heated adjacent cells which went into thermal runaway.

- Joined

- 9 October 2009

- Messages

- 21,969

- Reaction score

- 13,616

http://www.washingtontimes.com/news/2013/feb/3/boeings-787-dreamliners-grounded-batteries-can-fly/

At the same time the government certified Boeing’s 787 Dreamliners as safe, federal rules barred the type of batteries used to power the airliner’s electrical systems from being carried as cargo on passenger planes because of the fire risk.

Now the situation is reversed.

Dreamliners worldwide were grounded nearly three weeks ago after lithium ion batteries that are part of the planes led to a fire in one plane and smoke in a second. But new rules exempt aircraft batteries from the ban on large lithium ion batteries as cargo on flights by passenger planes.

In effect, that means the Dreamliner’s batteries are now allowed to fly only if they’re not attached to a Dreamliner.

The regulations were published on Jan. 7, the same day as a battery fire in a Japan Airlines 787 parked at Boston's Logan International Airport that took firefighters nearly 40 minutes to put out. The timing of the two events appears coincidental.

Pilots and safety advocates say the situation doesn’t make sense. If the 787’s battery system is too risky to allow the planes to fly, then it’s too risky to ship the same batteries as cargo on airliners, they said.

- Joined

- 9 October 2009

- Messages

- 21,969

- Reaction score

- 13,616

Japan: No Evidence Boeing Dreamliner Battery Was Overcharged (WSJ.com)

....At this point, investigators on both sides of the Pacific have essentially ruled out overcharged batteries in both events. But in casting a wide net to look at charging systems as well various other hardware and software related to the battery, they haven't yet publicly identified a specific cause in either incident. U.S. investigators on Thursday are expected to unveil preliminary conclusions about whether they found internal battery problems, according to people familiar with the details.

People familiar with the matter said that the FAA's leadership and officials of Japan's transport ministry already have had some preliminary exchanges with Boeing about a range of potential corrective actions that would allow the global fleet of 50 jets to resume flying.

Initially, Japanese officials said they suspected overcharging was the most likely cause of the cockpit warning and burning odor that prompted pilots on an All Nippon Airways Co. 787 last week to make an emergency landing on a domestic flight.

But on Wednesday, Norihiro Goto, the chairman of the Japan Transport Safety Board, told reporters at a news conference that data acquired from the ANA Dreamliner's digital flight-data recorder showed there was nothing "abnormal" in the battery's voltage level before a series of alarms went off in the plane's cockpit.

The data found on the digital flight data recorder of the ANA Dreamliner showed that the output voltage of the battery didn't exceed the maximum 32 volts, according to Mr. Goto. It had stayed at 31 volts before suddenly dropping and then moving up and down, indicating that overcharging may not have been the cause of the incident.

A team led by U.S. experts is delving into a Jan. 7 battery fire on a parked Japan Airlines Co. 787 in Boston, which was hot enough to melt some metal supports for the battery. Prior to Wednesday, public statements by U.S. and Japanese investigators suggested that to some extent, U.S. and Japanese investigators were pursuing divergent theories.

The latest finding, however, brings the Japanese effort more in line with what U.S. investigators found after the Boston incident, according to people familiar with the matter. The National Transportation Safety Board said earlier this week that the JAL 787's battery "did not exceed its designed voltage.''

The twists of the U.S. and Japan probes underscore the difficulty of troubleshooting the advanced electrical system that powers Boeing's flagship jet.

FAA officials don't suspect internal battery defects were the main culprits in the two incidents, according to people familiar with the probes, nor have U.S. inspections on other 787 aircraft provided such evidence. New details from continuing laboratory work could alter those conclusions, but for now investigators confront the formidable task of analyzing the interplay of complex circuits to try to get to the bottom of what happened. At the same time, FAA officials are conducting a sweeping review of 787 design and production intended to look beyond batteries.....

- Joined

- 9 October 2009

- Messages

- 21,969

- Reaction score

- 13,616

Original caption: Six of the eight cells in the ANA 787's overheated battery are severely charred. (Provided by the Japan Transportation Safety Board)

http://ajw.asahi.com/article/economy/business/AJ201302050117

2IDSGT

Ah tale yew wut!

- Joined

- 27 November 2012

- Messages

- 365

- Reaction score

- 14

I don't understand. All indications point toward a fundamentally flawed battery design, so why hasn't Boeing started the process of certifying an alternative? I don't know how long that would take, but I'm starting to pick up some living-in-denial vibes here. Is GS Yuasa's crappy product really that integral to the overall electrical system? If so, I can understand why Boeing is standing pat in the forlorn hope that they can avoid billions in delays/redesigns, but the problem isn't going to solve itself.

Bill Walker

Per Ardua ad Nauseum

I was sort of wondering the same thing. Hopefully they have one team trying to understand the current battery and control system, and another team working on a replacement - but it may not be as easy as just replacing the battery. The scrutiny from the FAA (and others) will be very intense right now, so I suspect the whole electrical system, and the mechanical installation of the battery, is probably being second-guessed to death as we speak.

2IDSGT

Ah tale yew wut!

- Joined

- 27 November 2012

- Messages

- 365

- Reaction score

- 14

Doesn't look that way. http://www.aviationweek.com/Article.aspx?id=/article-xml/AW_02_04_2013_p20-543232.xmlBill Walker said:I was sort of wondering the same thing. Hopefully they have one team trying to understand the current battery and control system, and another team working on a replacement...

So basically, the MBAs running the company are just going to stick their heads in the sand and hope for a quick fix....Despite the evidence from the Japan Airlines and All Nippon Airways aircraft incidents in January, the latest signs indicate Boeing believes its best option for recovery is to modify the existing battery. If this remains the case, even after the root causes are known, the questions become: What extra safeguards are required? Will those satisfy the regulatory authorities? And how quickly can they be implemented? Among the modifications being examined by Boeing is a containment system for the 63-lb. battery improved to endure prolonged exposure to fire, as well as additional temperature monitors.

Officially, however, as the batteries continue to be inspected and torn down by the U.S. NTSB and Japan Transport Safety Board (JTSB), solutions remain elusive. For Boeing, the specter of certifying a new or replacement battery system and supporting hardware lingers, along with the inevitable lengthy certification effort and cost impact to the program...

Boeing is intent on steering clear of this fate, as indicated by CEO James McNerney during the company's Jan. 30 fourth-quarter results call. “Nothing we've learned yet has told us that we have made the wrong choice on the battery technology,” McNerney said, despite limitations imposed on him by the ongoing FAA, NTSB and JTSB investigations. “We feel good about the battery technology and its fit for the airplane.”

antigravite

ACCESS: Top Secret

- Joined

- 25 April 2008

- Messages

- 836

- Reaction score

- 258

Whisteblowers now have entered the scene. A certain Mr Leon from Securaplane has a very interesting story. CNBC titled its article "Whisteblower says Dreamliner batteries could 'explode'". Check this out!

http://www.rightinginjustice.com/news/2013/02/01/investigators-consider-whistleblower-claims-in-boeing-dreamliner-probe/

http://www.reuters.com/article/2013/01/24/uk-boeing-787-ntsb-idUSLNE90N00T20130124

http://www.cnbc.com/id/100406310/Whistleblower_Says_Dreamliner_Batteries_Could_lsquoExplodersquo

A.

http://www.rightinginjustice.com/news/2013/02/01/investigators-consider-whistleblower-claims-in-boeing-dreamliner-probe/

http://www.reuters.com/article/2013/01/24/uk-boeing-787-ntsb-idUSLNE90N00T20130124

http://www.cnbc.com/id/100406310/Whistleblower_Says_Dreamliner_Batteries_Could_lsquoExplodersquo

A.

2IDSGT

Ah tale yew wut!

- Joined

- 27 November 2012

- Messages

- 365

- Reaction score

- 14

Old news, already discounted since:antigravite said:Whisteblowers now have entered the scene. A certain Mr Leon from Securaplane has a very interesting story. CNBC titled its article "Whisteblower says Dreamliner batteries could 'explode'". Check this out!

http://www.rightinginjustice.com/news/2013/02/01/investigators-consider-whistleblower-claims-in-boeing-dreamliner-probe/

http://www.reuters.com/article/2013/01/24/uk-boeing-787-ntsb-idUSLNE90N00T20130124

http://www.cnbc.com/id/100406310/Whistleblower_Says_Dreamliner_Batteries_Could_lsquoExplodersquo

A.

1- the problems appears to be with the batteries themselves and not the chargers.

2- the chargers in question were never installed on aircraft.

From your Reuters article:

...The FAA looked into Leon's complaints in 2008 and 2009, but concluded that the equipment he had expressed concerns about were prototypes that were never installed on the 787...

- Joined

- 9 October 2009

- Messages

- 21,969

- Reaction score

- 13,616

Boeing Preps Redesign to Get 787 Flying Again (WSJ.com)

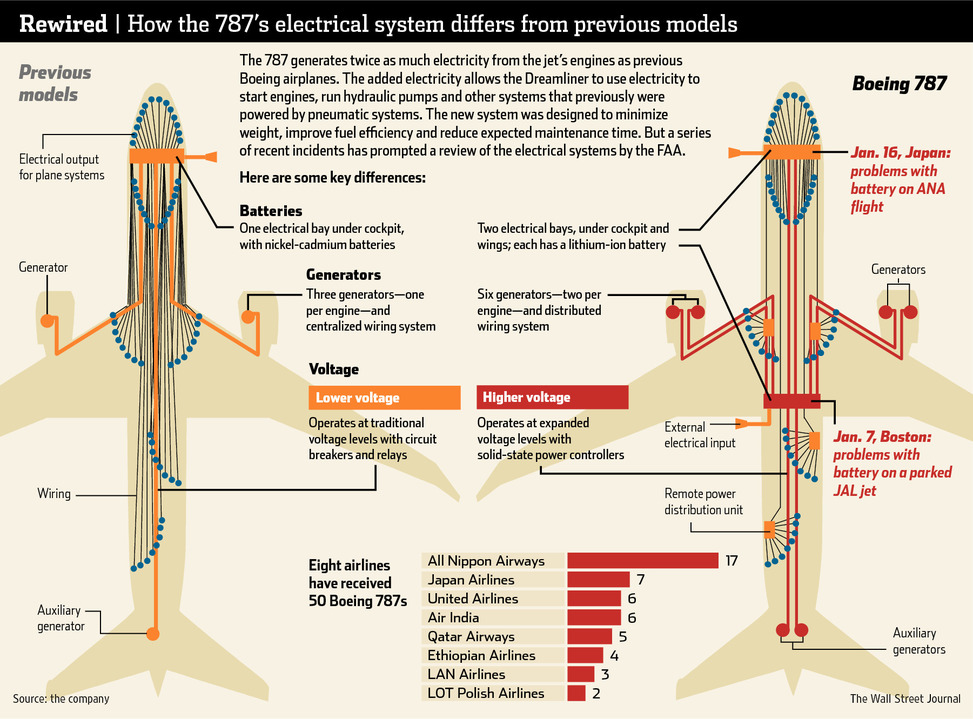

[IMAGE CREDIT: The Wall Street Journal/ Boeing]

Boeing Co. is proposing a series of battery design changes that it believes would minimize the risks of fire on its 787 Dreamliners and allow the grounded jets to fly again while it continues searching for a longer-term fix, say government and industry officials briefed on the matter.

The company is looking at increasing the separation between cells in the lithium-ion batteries to reduce the potential hazards from heat or fire spreading within the batteries and adding enhanced heat-sensors, these officials said. Boeing also is considering ways to keep cells more rigid, preventing them from shifting under certain conditions and interfering with electronics.

The goal would be a new, safer battery that Boeing could propose for the 50 Dreamliners currently grounded around the world, and on future deliveries, the people said.

[IMAGE CREDIT: The Wall Street Journal/ Boeing]

- Joined

- 9 October 2009

- Messages

- 21,969

- Reaction score

- 13,616

http://www.flightglobal.com/news/articles/jal-mulls-767-retention-as-787-grounding-continues-382020/

2IDSGT

Ah tale yew wut!

- Joined

- 27 November 2012

- Messages

- 365

- Reaction score

- 14

More evidence that the battery's design/manufacture is fundamentally flawed. http://www.wired.com/autopia/2013/02/ntsb-787-dreamliner/

Looks like Chevrolet and Tesla both took precautionary measures that apparently didn't occur to Yuasa for a 1/4 billion dollar airliner with HUNDREDS of people on board. I'll stop short of saying Boeing needs to abandon LI tech altogether (Airbus is already thinking about it), but I'm still confused as to why they aren't trying to source/certify 1-2 other vendors. This better not be something about helping the Japanese "save-face."

Looks like Chevrolet and Tesla both took precautionary measures that apparently didn't occur to Yuasa for a 1/4 billion dollar airliner with HUNDREDS of people on board. I'll stop short of saying Boeing needs to abandon LI tech altogether (Airbus is already thinking about it), but I'm still confused as to why they aren't trying to source/certify 1-2 other vendors. This better not be something about helping the Japanese "save-face."

2IDSGT

Ah tale yew wut!

- Joined

- 27 November 2012

- Messages

- 365

- Reaction score

- 14

http://www.wired.com/autopia/2013/02/boeing-787-battery-flight-test/

Here's an idea Boeing. Why don't you build a rig on the ground that can bench-test MORE THAN 2 F*CKING BATTERIES AT ONCE with simulated flight cycles?Boeing Begins Flight Testing of 787 Dreamliner to Find Battery Faults

...Boeing was allowed to make a one-time ferry flight of a Dreamliner from its Texas paint shop to the factory north of Seattle last Thursday. On Saturday the company prepared its only remaining active flight test aircraft, ZA005, at Boeing Field in Seattle for a preliminary test flight. The airplane departed Boeing Field Saturday morning and, as dictated by the FAA, flew over the sparsely populated areas in the eastern half of Washington state before finishing the two-hour, 19-minute flight over the Olympic Peninsula northwest of Seattle...

- Joined

- 11 February 2007

- Messages

- 2,561

- Reaction score

- 4,360

[quote author=2IDSGT]More evidence that the battery's design/manufacture is fundamentally flawed.

[/quote]

At the moment that's more evidence that the battery doesn't follow the same design paradigm as the Tesla's batteries, than evidence of a fatal flaw. It may be Boeing/Yuasa intended the risk to be addressed by some other mechanism, there isn't sufficient data to make a conclusive judgement (especially for those of us who aren't Lithium-Ion battery engineers).

Boeing will already have at least one battery test-rig in the form of the iron-bird for the electrical systems, possibly more depending on how they set up ground testing and integration. While an engineering rig could be built to simulate the operation cycle for the batteries across multiple battery systems at a time, a massive problem arises if it doesn't replicate the mechanism that's actually causing the problem, and we don't know precisely what that is yet. Attention is focussing on dendrite formation shorting out the batteries, but we haven't had that confirmed, we don't know why some batteries are affected and others aren't (cycles? cycle length? pressure, temperature, whatever) and we don't know why it's happening in the Yuasa batteries when it will have been one of the failure modes looked at. Test-flying the 787 will let Boeing conduct more rigorous measurement of every parameter they think may be relevant in order to a) feed back into the failure investigation programme, and b) contribute to any test rig design. I wouldn't be surprised to find the battery cells are being MRI-scanned before and after each flight to monitor their internal condition.

Airbus announced Friday they're dropping Li-Ion for the A350 and reverting to Ni-Cad. Even if they're confident in the technology, the risk of a knee-jerk ban by regulators probably makes that a sensible decision. http://www.reuters.com/article/2013/02/15/airbus-battery-idUSL5N0BF1S720130215

(Ironically my car's lead-acid battery failed a couple of weeks ago during the cold-snap, it's a Yuasa )

)

[/quote]

At the moment that's more evidence that the battery doesn't follow the same design paradigm as the Tesla's batteries, than evidence of a fatal flaw. It may be Boeing/Yuasa intended the risk to be addressed by some other mechanism, there isn't sufficient data to make a conclusive judgement (especially for those of us who aren't Lithium-Ion battery engineers).

To quote a famous saying on the relation of reality and models: 'the map is not the territory'. I've no background on 787, but 777 hit us with a bunch of surprises in flight-test (and service) that just hadn't come up in all the modelling and iron-bird testing done before the flight-test campaign. I was only paying attention to the Primary Flight Control System stuff, and only seeing what made it across the Pond (the 777 PFCS was developed by BAE Rochester), but just from memory we had some fairly spectacular stall behaviour ('I'm too old for this shit' to quote the PFCS flight test engineer after it flick-rolled 70 degrees right yet again), some markedly long landings at Edwards Air Force Base, and even after it was certified and in service, 'tail-wag' that was regularly making the passengers at the rear of cattle-class airsick. That's not counting the daily tweaking of flight-control laws that had been expected, nor, straying outside of PFCS territory, not one, but two decompression emergencies, at least one of which hospitalized some of the flight-test crew. And yet testing and modelling on 777 was supposed to have reached previously unseen levels of fidelity with real-world behaviour. And, after all that, both the 777 hull-losses to date were due to completely unexpected phenomena - ice crystals blocking the fuel heat-exchanger in the Heathrow crash and a short through the pilot's oxygen hose in the Cairo fire - with the ice-crystal issue taking considerable research to pin down and the oxygen hose short hypothesized rather than proved.Here's an idea Boeing. Why don't you build a rig on the ground that can bench-test MORE THAN 2 F*CKING BATTERIES AT ONCE with simulated flight cycles?

Boeing will already have at least one battery test-rig in the form of the iron-bird for the electrical systems, possibly more depending on how they set up ground testing and integration. While an engineering rig could be built to simulate the operation cycle for the batteries across multiple battery systems at a time, a massive problem arises if it doesn't replicate the mechanism that's actually causing the problem, and we don't know precisely what that is yet. Attention is focussing on dendrite formation shorting out the batteries, but we haven't had that confirmed, we don't know why some batteries are affected and others aren't (cycles? cycle length? pressure, temperature, whatever) and we don't know why it's happening in the Yuasa batteries when it will have been one of the failure modes looked at. Test-flying the 787 will let Boeing conduct more rigorous measurement of every parameter they think may be relevant in order to a) feed back into the failure investigation programme, and b) contribute to any test rig design. I wouldn't be surprised to find the battery cells are being MRI-scanned before and after each flight to monitor their internal condition.

Airbus announced Friday they're dropping Li-Ion for the A350 and reverting to Ni-Cad. Even if they're confident in the technology, the risk of a knee-jerk ban by regulators probably makes that a sensible decision. http://www.reuters.com/article/2013/02/15/airbus-battery-idUSL5N0BF1S720130215

(Ironically my car's lead-acid battery failed a couple of weeks ago during the cold-snap, it's a Yuasa

2IDSGT

Ah tale yew wut!

- Joined

- 27 November 2012

- Messages

- 365

- Reaction score

- 14

@DWG You're right, I'm no engineer; but two still things are fairly obvious.

1. The Yuasa batteries have a manufacturing or design weakness that can cause failure in any part of any cell of any battery at any time. So, while the problem may be infrequent, it is also random, the worst possible combination. Spooling up different design with another vendor for certification just makes common sense.

2. Boeing needs to observe a failure under instrumentation. Given the random/infrequent nature of the problem, this means testing as many batteries as possible, not just 4 in the prototype and the iron bird.

1. The Yuasa batteries have a manufacturing or design weakness that can cause failure in any part of any cell of any battery at any time. So, while the problem may be infrequent, it is also random, the worst possible combination. Spooling up different design with another vendor for certification just makes common sense.

2. Boeing needs to observe a failure under instrumentation. Given the random/infrequent nature of the problem, this means testing as many batteries as possible, not just 4 in the prototype and the iron bird.

- Joined

- 9 October 2009

- Messages

- 21,969

- Reaction score

- 13,616

787 Grounding Disrupts Norwegian’s Long-Haul Plans (Aviation Week)

2IDSGT

Ah tale yew wut!

- Joined

- 27 November 2012

- Messages

- 365

- Reaction score

- 14

Christ, how long has Cave Johnson been running Boeing? Unfortunately, his problem here isn't "reproducible human error."Grey Havoc said:787 Grounding Disrupts Norwegian’s Long-Haul Plans (Aviation Week)

http://www.youtube.com/watch?v=wX9Sc88qreg

- Joined

- 9 October 2009

- Messages

- 21,969

- Reaction score

- 13,616

On another note: Battery output finds positive side (Daily Yomiuri Online)

- Joined

- 11 February 2007

- Messages

- 2,561

- Reaction score

- 4,360

I don't think the evidence supports a 'random' failure, more one we don't yet understand the relevant factors for, c.f. the string of electrical failures on 787 at the end of last year that had only been seen once before, and then it dawned on people the boards that were failing were all from the same batch and had a manufacturing flaw, 'random' generally just means something we don't understand yet.2IDSGT said:@DWG You're right, I'm no engineer; but two still things are fairly obvious.

1. The Yuasa batteries have a manufacturing or design weakness that can cause failure in any part of any cell of any battery at any time. So, while the problem may be infrequent, it is also random, the worst possible combination. Spooling up different design with another vendor for certification just makes common sense.

If Boeing want to stay with Li-Ion, and even if they want to stick with Ni-Cad, there's considerable reason to stay with Yuasa - familiarity with the operating environment, familiarity with risks, familiarity with Boeing engineering processes, existing relationship with Boeing engineering staff and FAA reps, and so on, even familiarity of relevant Yuasa staff with Seattle. That's not something that really shows up in raw stats or headlines, but it makes it much easier for teams to work together - I had a Boeing QA guy at the next desk through much of the 777 PFCS development and a bunch of colleagues over in Seattle working almost daily in the iron bird or the simulators with the Boeing guys. We got to the point we could have Boeing send out a change request at the end of their day, we'd pick it up in our morning in Rochester, implement it, test it, and have it ready to fly next morning in Seattle, and that was only possible because of a relationship that had had several years to bed down. The Yuasa battery might have problems, but the 777 control laws had problems with spectacularly unsuitable stall behaviour, with hysterical headlines in the Seattle press just like the batteries, it just needed a few days to analyse what was going on and implement a fix. We're looking at longer to fix the battery, because the problem is less clear, but that's true whoever does the work.

Swapping out the entire manufacturer becomes a considerably larger problem, involving potentially certiyfing their entire works if they don't have an existing relationship with Boeing and/or the FAA. It might become necessary if Yuasa can't implement a fix because someone else holds the intellectual property rights to the necessary technology and won't license it, but that's very much a solution you would want to avoid if possible, because it will almost inevitably take longer.

You can test as many batteries as you like, but if the failure depends on a specific set of conditions, then no matter how many batteries you test you won't get a failure unless the conditions are right. Better to spend a few days extra determining exactly how to provoke a failure, than spend weeks doing testing that takes you nowhere.2. Boeing needs to observe a failure under instrumentation. Given the random/infrequent nature of the problem, this means testing as many batteries as possible, not just 4 in the prototype and the iron bird.

- Joined

- 9 October 2009

- Messages

- 21,969

- Reaction score

- 13,616

From Aviation Week (Things With Wings blog):

If the proposed battery fix that Boeing will present to the FAA in DC as early as tomorrow is accepted, the scene below may not be seen for much longer. This photo was taken by Joe Walker at Paine Field last weekend. Four new 787s are parked at the base of the tower. ANA's JA818A, JAL's JA830J and two LOT 787s - SP–LRD and SP-LRE are seen here.

Bill Walker

Per Ardua ad Nauseum

DWG said:If Boeing want to stay with Li-Ion, and even if they want to stick with Ni-Cad, there's considerable reason to stay with Yuasa - familiarity with the operating environment, familiarity with risks, familiarity with Boeing engineering processes, existing relationship with Boeing engineering staff and FAA reps, and so on, even familiarity of relevant Yuasa staff with Seattle.

But surely Boeing HAS these relationships with other battery vendors, or at least for other battery types. What is in all those 737s , 777s, etc. rolling out the doors these days? I'm still surprised there is no apparent "Plan B" in the works, replacing the LI-Ion batteries with ANYTHING else, even if it is only for a few months. Boeing is facing huge right now costs with undelivered aircraft, and huge later on costs with upset customers.

I wonder if there is more to this than we have been told so far. Are there doubts about the basic charging and regulating system, that need to be fixed before any battery would work in the 787? Is Boeing relieved to not be delivering 787s for some other, not yet apparent reason? Let the conspiracy theories begin.

Bill Walker

Per Ardua ad Nauseum

This just arrived in my in-basket this morning. Looks like there is a Plan B, but not what one might expect.

http://www.chicagotribune.com/business/sns-mct-boeing-readies-short-term-battery-fix-facing-20130217,0,5674886.story?goback=%2Egde_911907_member_215522175

http://www.chicagotribune.com/business/sns-mct-boeing-readies-short-term-battery-fix-facing-20130217,0,5674886.story?goback=%2Egde_911907_member_215522175

2IDSGT

Ah tale yew wut!

- Joined

- 27 November 2012

- Messages

- 365

- Reaction score

- 14

Wow, that sound exactly like something Aperture Sciences would do:Bill Walker said:This just arrived in my in-basket this morning. Looks like there is a Plan B, but not what one might expect.

http://www.chicagotribune.com/business/sns-mct-boeing-readies-short-term-battery-fix-facing-20130217,0,5674886.story?goback=%2Egde_911907_member_215522175

"Cave Johnson here. As you may have heard, we're having a little trouble with our new 787 airliners. Seems the FAA thinks that it's bad for planes to spontaneously catch on fire. Now I know what you're all thinking: 'hey Cave, why don't you fix the planes so they don't catch fire?' Well, that's not how we do things here. No, we here at Aperture think outside the box; specifically, the battery box. That's right folks, our solution to this problem is to modify our battery boxes in order to build the first airplane ever that's perfectly safe to fly while it's burning..."

Bill Walker

Per Ardua ad Nauseum

Well, it sorta makes sense after thinking about it. As the newspaper article pointed out, lead acid and Ni-Cad batteries still catch fire regularly. The difference is people know this, and understand the mechanisms. As a result, battery installations have evolved over the years to the point where a battery fire is not that big a deal - relatively. I guess we need the same development with new battery formats. I don't see that this replaces the need to understand the root cause of the fire and take mitigating action, but it is probably a necessary parallel activity.

- Joined

- 9 October 2009

- Messages

- 21,969

- Reaction score

- 13,616

http://ajw.asahi.com/article/economy/business/AJ201302200094

- Joined

- 11 February 2007

- Messages

- 2,561

- Reaction score

- 4,360

As the article you linked to in your next post makes clear, the 787 is unique in being the 'more electric airplane' - the need to do with electrical power what every other plane flying, including 737 and 777, does with hydraulics means that 787 has a unique battery system set of requirements that switching to Ni-Cad would make far more difficult to achieve. That makes changing technology far more difficult, but also makes changing battery supplier more difficult, as only Yuasa have built a Li-Ion battery to that set of requirements. If you implement a technology you haven't used before, FAA will require the whole production process to be certified at a level of detail above that required of someone already using it. And beyond that, even if Boeing were to swap suppliers, they can't swap regulator, and the battery was developed to a one-off, special set of requirements. There are senators trying to haul FAA in front of sub-committees because of that and you can guarantee the FAA is looking very hard at what it will require of Boeing in order to allow the 787 to fly in passenger service again.Bill Walker said:DWG said:If Boeing want to stay with Li-Ion, and even if they want to stick with Ni-Cad, there's considerable reason to stay with Yuasa - familiarity with the operating environment, familiarity with risks, familiarity with Boeing engineering processes, existing relationship with Boeing engineering staff and FAA reps, and so on, even familiarity of relevant Yuasa staff with Seattle.

But surely Boeing HAS these relationships with other battery vendors, or at least for other battery types. What is in all those 737s , 777s, etc. rolling out the doors these days?

Bill Walker

Per Ardua ad Nauseum

DWG said:As the article you linked to in your next post makes clear, the 787 is unique in being the 'more electric airplane' - the need to do with electrical power what every other plane flying, including 737 and 777, does with hydraulics means that 787 has a unique battery system set of requirements that switching to Ni-Cad would make far more difficult to achieve.

Doesn't it just mean more Ni-Cads to do the same job? Amp-hours are amp-hours, wherever they come from. I wonder what Boeing customers would think of these two options:

1. Wait 6 months (or longer) till we sort out the batteries, with your fleet grounded, or

2. Fly with two less paying passengers, and Ni-Cads, in 2 months. Then, a year later, we give you back those 2 passengers.

That makes changing technology far more difficult, but also makes changing battery supplier more difficult, as only Yuasa have built a Li-Ion battery to that set of requirements.

I suspect the main requirement was amp-hours per pound, plus charging speed. If you give up a little weight (as a % of the whole aircraft) you could do it all with Ni-Cads. Or even lead-acid, for a little more weight.

If you implement a technology you haven't used before, FAA will require the whole production process to be certified at a level of detail above that required of someone already using it.

Again, the Ni-Cad regulators are not new. You just need more of them.

And beyond that, even if Boeing were to swap suppliers, they can't swap regulator, and the battery was developed to a one-off, special set of requirements.

Stuck record here: Ni-Cad batteries. Ni-Cad voltage control systems. Ni-Cad charging systems. All in production, all in use at Boeing, bazillion hours flight experience.

There are senators trying to haul FAA in front of sub-committees because of that and you can guarantee the FAA is looking very hard at what it will require of Boeing in order to allow the 787 to fly in passenger service again.

I agree the FAA should be nervous, and hard questions will have to be answered.

- Joined

- 11 February 2007

- Messages

- 2,561

- Reaction score

- 4,360

Going back to that article you linked to: "as Teal Group aviation analyst Richard Aboulafia points out, ... the 787 uses electricity for those systems, and so it requires a high-energy, quickly recharging backup power source.Bill Walker said:DWG said:As the article you linked to in your next post makes clear, the 787 is unique in being the 'more electric airplane' - the need to do with electrical power what every other plane flying, including 737 and 777, does with hydraulics means that 787 has a unique battery system set of requirements that switching to Ni-Cad would make far more difficult to achieve.

Doesn't it just mean more Ni-Cads to do the same job? Amp-hours are amp-hours, wherever they come from.

"Boeing needs a faster response time," said Aboulafia. "It needs lithium ion.""

Aboulafia's one of the most respected analysts in the business, dismissing his opinion wouldn't be wise. Boeing is trying to stay with Li-Ion, no matter the uncertainty, it's not simply a case of dropping Ni-Cads in, that would trigger a recertification process of its own (because by definition 787 is more dependent on its batteries and uses them harder than any other aircraft) that might take as long, or even longer, than the fix to Li-Ion. We also shouldn't forget that FAA had ordered a complete review of the 787's systems (which was itself pretty much unprecedented) just 4 days before the grounding, given the circumstances I suspect they will want that completed as well as resolution of the battery issues before they allow resumption of revenue service.

787 has a credibility problem, it was four years late, it still has aircraft being reworked after production, and it now faces an extended grounding. Saying 'we'll fix it in a year' leaves Boeing facing a major ongoing PR disaster as Airbus bring the A350 into service, with potentially catastrophic damage to every ongoing sales campaign, when A320 Neo has already hammered 737 Max. Because of the way airlines buy aircraft Boeing risk losing major customers across all lines, not just 787. And then there is the industry chatter, Akbar Al Baker of Qatar Airlines is extremely influential, was extremely unhappy with the 4 year delay, forced a major compensation package from Boeing, and is likely to start making extremely damaging comments if the 787 faces an extended grounding, or an extended period of not meeting it's contractually guaranteed performance. c.f.I wonder what Boeing customers would think of these two options:

1. Wait 6 months (or longer) till we sort out the batteries, with your fleet grounded, or

2. Fly with two less paying passengers, and Ni-Cads, in 2 months. Then, a year later, we give you back those 2 passengers.

http://www.flightglobal.com/news/articles/routes-al-baker-blasts-boeings-failure-over-787-deliveries-377099/

http://www.flightglobal.com/news/articles/al-baker-very-disappointed-after-latest-787-grounded-by-electrical-issue-380206/

It's not simply a weight issue, at an absolute minimum it's volume as well, and the energy density of Li-Ion is significantly better than Ni-Cad (250-620 W H/L vs 50-150 W h/l), which means that you're looking at potentially quadrupling the volume needed in the battery bays, and that's a significant structural issue, meaning certifying a retrofit programme, and then doing a significant upgrade on each aircraft, at a time when Boeing was trying to convince everyone it was done with post-manufacture changes to 787, it is not a case of a drop in replacement. What I've read from commentators such as Aboulafia leads me to suspect there are also issues with charge/discharge cycles or other aspects of battery performance that make Li-Ion the significantly better choice for 787, and possibly the only choice. What's clear is Boeing is desperate not to change from Li-Ion, and with the ongoing damage being caused by the grounding, there have to be significant engineering reasons for that.If you give up a little weight (as a % of the whole aircraft) you could do it all with Ni-Cads. Or even lead-acid, for a little more weight.

I don't actually think FAA's actions WRT Li-Ion certification have been unreasonable, there are parallels with how certification of the 777 FCS was handled - FAA didn't have the necessary expertise, so they subcontracted to someone who did to determine how certification would proceed. There are probably plenty of similar examples, but to people who aren't familiar with the issues, or have an axe to grind, FAA's actions may look questionable. I think FAA may therefore be exceptionally cautious in how it proceeds with allowing the 787 back into revenue service.I agree the FAA should be nervous, and hard questions will have to be answered.

United have announced today they're dropping the 787 from service through 5th June, with a possible exception for a Denver-Tokyo route due to start 12th May. with the necessary range. And LOT have dropped it through October. http://www.reuters.com/article/2013/02/22/unitedcontinental-idUSL1N0BL8PE20130222

Aeroengineer1

Engineering, not just a job, but a lifestyle :)

- Joined

- 27 January 2008

- Messages

- 122

- Reaction score

- 102

DWG,

It is so nice to see another engineer on the board. Your presentations have been clear and reasonable. I think that the world we live in is so caught up in marketing hype that they really do not understand the concept of trade-offs and risk. Life is always with risks. Some of these risks have the potential consequence of the loss of life. It is the job of the engineers combined with management to reduce those risks while still being able to make a product that people can afford while still having the necessary utility that was desired.

Working in aerospace and engineering myself, I can tell you that I am well aware that the things that I do has the potential to cause someone the loss of life. Because of this I work diligently to understand the problem and create the best product that mitigates the known risks. In the end, it is the unknown/undiscovered risks that usually are the ones that cause the problem. This appears to be the case here with the battery issue.

Adam

It is so nice to see another engineer on the board. Your presentations have been clear and reasonable. I think that the world we live in is so caught up in marketing hype that they really do not understand the concept of trade-offs and risk. Life is always with risks. Some of these risks have the potential consequence of the loss of life. It is the job of the engineers combined with management to reduce those risks while still being able to make a product that people can afford while still having the necessary utility that was desired.

Working in aerospace and engineering myself, I can tell you that I am well aware that the things that I do has the potential to cause someone the loss of life. Because of this I work diligently to understand the problem and create the best product that mitigates the known risks. In the end, it is the unknown/undiscovered risks that usually are the ones that cause the problem. This appears to be the case here with the battery issue.

Adam

Aeroengineer1 said:DWG,

It is so nice to see another engineer on the board. Your presentations have been clear and reasonable. I think that the world we live in is so caught up in marketing hype that they really do not understand the concept of trade-offs and risk. Life is always with risks. Some of these risks have the potential consequence of the loss of life. It is the job of the engineers combined with management to reduce those risks while still being able to make a product that people can afford while still having the necessary utility that was desired.

Agree fully Adam. I would however say that it is not only Engineers who understand such things - many in management roles do as well. Moreover, unfortunately not all engineers (and yes, I have an engineering degree as well, although I no longer practice as an engineer) understand this. I have seen many instances where engineers and other technical people operate in a seemingly black/white environment and don't understand that in the real world there are always trade-offs/compromises to be made. The impact of these are always hoped to be minimal, but alas sometimes there are simply unknowns that creep up to surprise you.

Aeroengineer1

Engineering, not just a job, but a lifestyle :)

- Joined

- 27 January 2008

- Messages

- 122

- Reaction score

- 102

I have seen many instances where engineers and other technical people operate in a seemingly black/white environment and don't understand that in the real world there are always trade-offs/compromises to be made.

You mean analysts

Once again good to know there is another voice of reason. What branch of engineering did you work in?

Adam

Was Mechanical by training though worked in Airframe and Propulsion.

- Joined

- 11 February 2007

- Messages

- 2,561

- Reaction score

- 4,360

Adam, GTX, agree 100%!

I'm a software engineer by training myself, though I increasingly strayed across the line into quality and config management as time went on. Background was HUDs, then Flight Controls, then weapon management systems, the vast majority real-time safety-critical.

Having worked on 777 I probably tend to follow the airline side of aviation more than most, and across a couple of decades that gives a reasonable insight into not just the engineering concerns*, but all the non-engineering factors that's going to impact the decisions people are making - I don't envy Boeing the problem they're facing.

*OTOH the problem being batteries makes the engineering concerns even more of a black art than hardware normally is

I'm a software engineer by training myself, though I increasingly strayed across the line into quality and config management as time went on. Background was HUDs, then Flight Controls, then weapon management systems, the vast majority real-time safety-critical.

Having worked on 777 I probably tend to follow the airline side of aviation more than most, and across a couple of decades that gives a reasonable insight into not just the engineering concerns*, but all the non-engineering factors that's going to impact the decisions people are making - I don't envy Boeing the problem they're facing.

*OTOH the problem being batteries makes the engineering concerns even more of a black art than hardware normally is

- Joined

- 9 October 2009

- Messages

- 21,969

- Reaction score

- 13,616

http://www.reuters.com/article/2013/02/27/us-boeing-dreamliner-pilots-idUSBRE91Q17120130227

http://www.reuters.com/article/2013/03/02/us-boeing-787-oversight-idUSBRE92104W20130302

http://www.reuters.com/article/2013/02/28/uk-boeing-dreamliner-report-idUSLNE91R00G20130228

http://www.reuters.com/article/2013/03/02/us-boeing-787-oversight-idUSBRE92104W20130302

http://www.reuters.com/article/2013/02/28/uk-boeing-dreamliner-report-idUSLNE91R00G20130228

- Joined

- 9 October 2009

- Messages

- 21,969

- Reaction score

- 13,616

http://www.reuters.com/article/2013/03/01/us-boeing-dreamliner-jobs-idUSBRE91R1P420130301

http://online.wsj.com/article/SB10001424127887324662404578335290305576244.html

http://online.wsj.com/article/SB10001424127887324662404578335290305576244.html

- Joined

- 9 October 2009

- Messages

- 21,969

- Reaction score

- 13,616

787: design change for dummies (Aviation Week/ Things With Wings blog)

Original Caption: An interesting graphic of the components making up the current battery configuration (Boeing)

Original Caption: An interesting graphic of the components making up the current battery configuration (Boeing)

- Joined

- 9 October 2009

- Messages

- 21,969

- Reaction score

- 13,616

CHICAGO (Jiji Press)--Boeing Co. Commercial Airplanes Chief Executive Officer Raymond Conner hinted at an early restart of operations of the firm's 787 planes, which have been grounded due to battery problems.

The company will move for an early resumption of the aircraft's operations if its measures to fix the batteries are approved by the U.S. Federal Aviation Administration, Conner said at a conference in New York on Monday.

On Feb. 22, Boeing submitted the measures to the FAA after battery problems occurred in January.

The FAA is expected to respond later this week, according to media reports. But the U.S. National Transportation Safety Board has yet to release a planned interim report on the problem.

(Mar. 6, 2013)

http://www.yomiuri.co.jp/dy/national/T130305004433.htm

- Joined

- 9 October 2009

- Messages

- 21,969

- Reaction score

- 13,616

http://www.bbc.co.uk/news/business-21710577

Similar threads

-

-

Wartime archive lists secret codes disguised as weather forecasts[Asahi Shimbun]

- Started by Grey Havoc

- Replies: 0

-

-

-