NeilChapman

Interested 3rd party

- Joined

- 14 December 2015

- Messages

- 1,283

- Reaction score

- 481

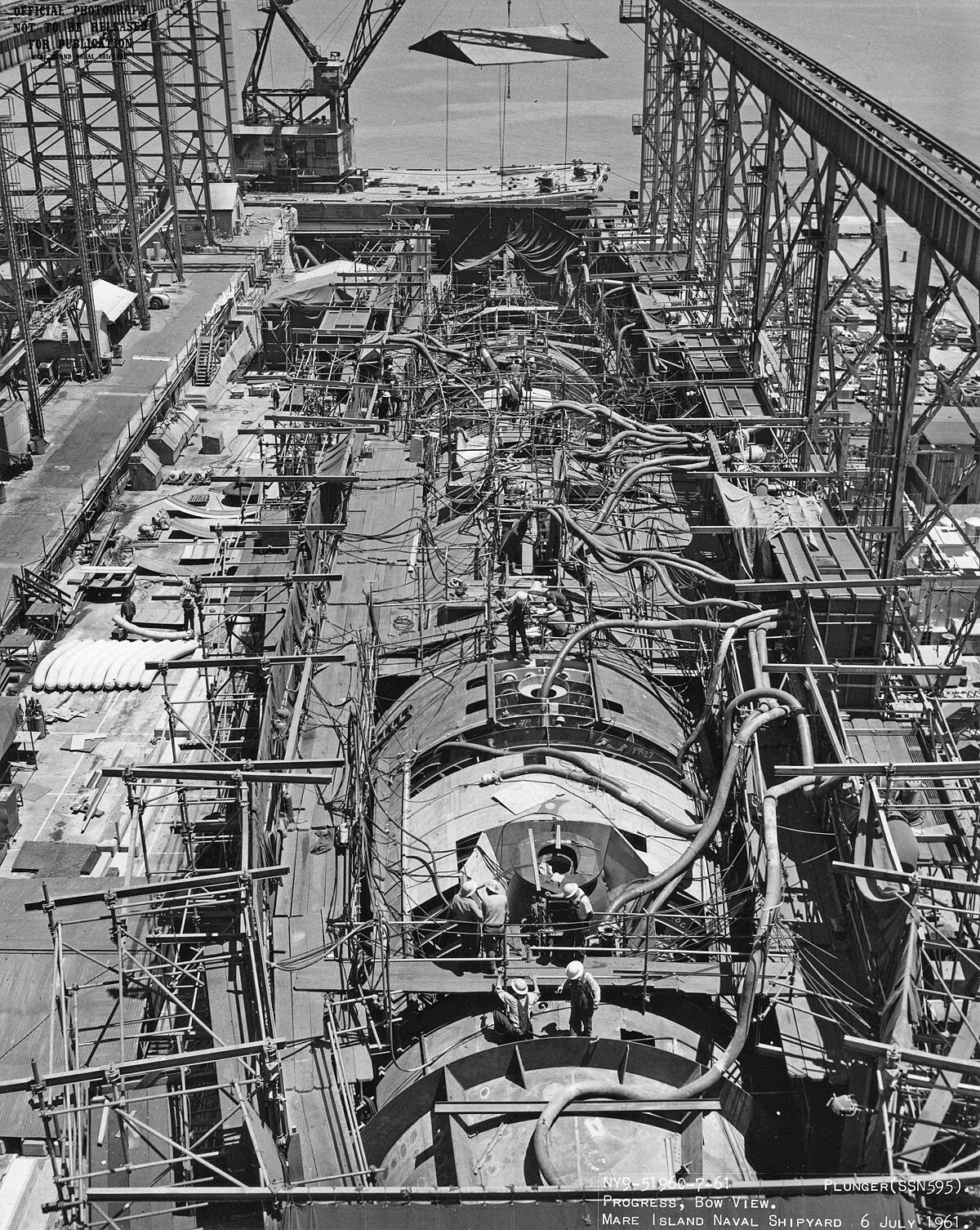

We're seeing a LOT of both companies' work, whichever yard is doing final assembly.

As an example: all the pressure hull ring sections come from EB's Quonset Point facility regardless of "whose" module it is inside the hull. Both from a material performance and cost perspective, using a single source to produce the hull rings makes a ton of sense...

... On the opposite side of the spectrum, Australia could stand up its own SSN hull ring production and not use the US-made hull rings at all, but that's probably the most expensive and slowest option.

If you're going to assume all the hull ring production for a 2040's boat why not build off Columbia-class tech and spec's using Virginia Payload Tubes and just call it Virginia Block VIII? The US has already bought down development costs for the drive system. Perhaps the Virginia-class replacement authorized in 2034 will be a Columbia varient.

Would it place too much risk on the Columbia deployment timeline? Hard to say. The US plans to have half its SSBN's ordered by 2030 and receiving them one per year by mid 2030's.