GE and P&W are developing 45K-class three-stream AETP demonstrators for F-35 retrofit, PCA/F-X, and F/A-XX. Official designations are XA100 for GE and XA101 for Pratt. Note the introduction of a new designator, A, to go along with J for turbojet and F for turbofan.

http://aviationweek.com/aviation-week-space-technology/sixth-gen-xa100-and-xa101-fighter-engine-studies-ramp

http://aviationweek.com/aviation-week-space-technology/sixth-gen-xa100-and-xa101-fighter-engine-studies-ramp

Sixth-Gen XA100 And XA101 Fighter-Engine Studies Ramp Up

Guy Norris | Aviation Week & Space Technology

May 9, 2017

The age of the adaptive cycle engine as a new class of combat aircraft propulsive system in its own right is edging closer to reality with detailed design now underway of the first three-stream demonstration units under the U.S. Air Force’s Adaptive Engine Transition Program (AETP).

AETP will mature three-stream engine technology for the future U.S. Navy F/A-XX and the Air Force’s F-X sixth-generation fighters. Targeted initially at the 45,000-lb.-thrust class, the engine is also baselined to fit within the existing confines of the F-35A engine bay, making it a contender to replace the Joint Strike Fighter’s current Pratt & Whitney F135 from the mid-2020s onward......

To underline the importance of this step toward a new generation of engine technology, the Air Force has broken with tradition by designating the two AETP demonstrators as the XA100 and XA101. Instead of following on from the F for “fan” or “turbofan” series, which most recently saw the F135/136s developed for the F-35, the new naming convention of “A” for adaptability is a milestone on a par with the designation “J” for the turbojet series in the 1940s. The XA100 is being developed by GE, and the XA101 by Pratt.

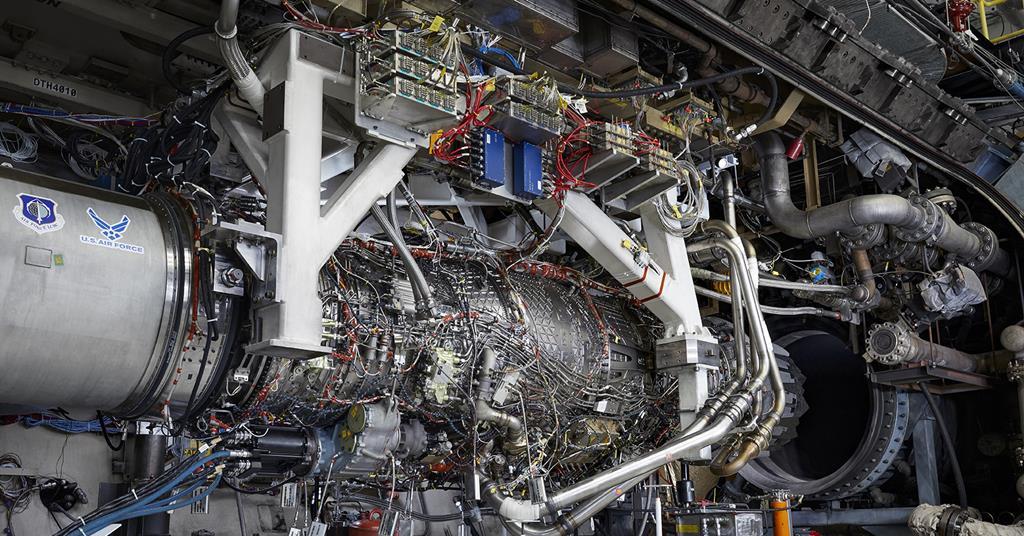

The company[GE] is progressing through the final phases of the AETD program by conducting component evaluations and running or evaluating data from three rig tests of a compressor, core engine and adaptive fan module. The compressor test, which was run at Wright-Patterson AFB, Ohio, was completed in September. “We have completed the analysis, and the data is flowing into AETP,” says McCormick. Work on the fan rig is ongoing in the same compressor research facility at Wright-Patterson. “That’s nearly complete, and we expect to finish sometime [in May],” he adds.

The third, and final, large-scale rig test is the core engine, also expected to wrap up late in May or early in June. “It is a pretty challenging program because it is very complex. With an adaptive cycle engine with the three streams and heat exchangers, when you run the core you have to simulate the rest of the engine. It is actually more complicated to run than a full-up engine test because we must adapt the facility to simulate the inputs from the rest of the engine,” McCormick explains.

Although the overall pace of testing has been slower than hoped, McCormick says: “We are still making great progress and have over 30 hr. of tests on the core.”....

As part of earlier AETD tests, GE ran an F414 with flaps and seals made from an oxide/oxide ceramic CMC similar to parts now used in the production version of the Passport business jet engine. An F414 was also fitted with second-stage low-pressure turbine blades made from another form of CMC. PMCs, which are composed of short or continuous fibers bound in an organic polymer matrix, are also well-known in the industry, and air splitters made from the PMC-based PMR-15 are widely used in engines. “The difference is where we are applying them, and using them in more complex parts,” says McCormick.

Although GE declines to provide a comprehensive AETP schedule, it is believed the detailed design review is slated for late 2017, followed by release of drawings for building a full engine. “We are actually starting into the supply-chain process now of getting hardware defined, so there is definitely an engagement,” says McCormick. The company is expected to build three test engines starting in 2019, with ground runs due later that year and set to run through 2020. The first engine will test the basic mechanical design of the engine, the second will assess performance and operability, and the third will assess durability...

Pratt, which has so far described very little of its AETP plan, was expected to have begun running an adaptive three-stream fan with an F135 earlier this year under the final phase of AETD.

PHOTO: Festooned with test wiring, GE’s Advanced Engine Technology Development program core demonstrator is close to completing evaluation in the company’s A1 test cell. Credit: GE