ADVANCEDBOY

ACCESS: Secret

- Joined

- 3 February 2011

- Messages

- 333

- Reaction score

- 83

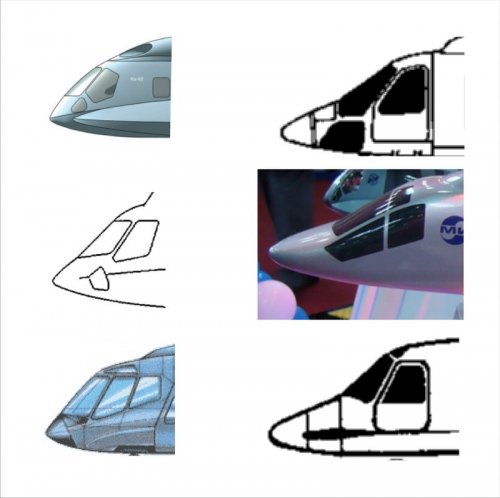

I know a lot you here are professionals, so ,please, help me out with this one. Firstly when I watched the unveiling of this brand new helicopter [the Bell 525 Relentless—Mod.], it left me with split feelings. It left a feeling as if it was not a new helicopter but a mishmash of older versions that has been stretched. It strangely reminded me of something that I have seen before. I haven`t done a scrupulous research to establish that, but my guess would veer towards Agusta-Westland, you know, somewhere towards AW-139. Besides, they have a facility in Philadelphia. When looking at Relentless in profile it seems too unnaturally skinny and stretched, and it doesn`t have solid design flow of lines from snout to tail section. If it was a brand new design, I believe designers would have made a smoother flow of skinny front section into thickenned middle section. Sorry to say that, but it reminds me somewhat the poor US truck industry, where a brand new truck is nothing else but a remastered front cowling and grille, while the front windshield and thick gasket around it reveals its aging mesosoic genome. Talking about beancounting hidden behind loud slogans. What was also suspsicious is the landing gear. Where else have I seen such an unproportionately skinny chassis? I don`t know, and I don`t want to sound like sour grapes, but my hunch makes me feel nervous about this one. Any comments?

![3046[1].JPG](/data/attachments/76/76133-9124c78edcaa627f569274a3475a0845.jpg)