Next Up for Lockheed Low-Speed HWB Airlifter: Flight

Aviation Week & Space Technology

Graham Warwick

Mon, 2016-03-07 04:00

Lockheed eyes demonstrator potential for unconventional airlifter concept

Scale wind-tunnel models are usually designed for one task, to collect data on the ground under strictly controlled conditions. But now that Lockheed Martin has completed low-speed testing of its Hybrid Wing Body (HWB) airlifter, it plans something unusual—to fly the same model as an unmanned aircraft.

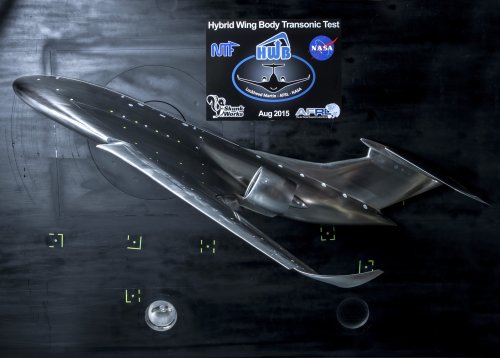

The February tests of a 4%-scale full-span model in Lockheed Martin’s low-speed wind tunnel in Marietta, Georgia, complemented evaluation of a same-scale half-span HWB in August 2015 in the National Transonic Facility (NTF) at NASA Langley Research Center. They are aimed at validating computational fluid dynamics (CFD) predictions of the unconventional configuration’s performance benefits.

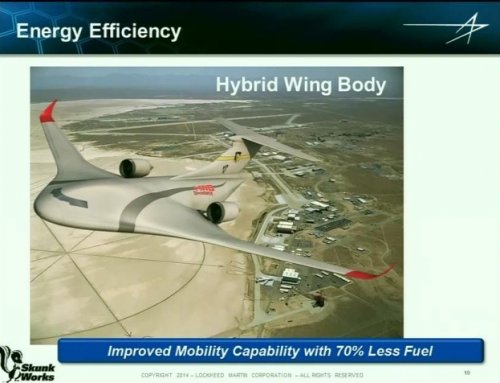

According to Lockheed, the HWB combines the aerodynamic and structural efficiency of a blended wing body with the control authority of a conventional T-tail for short-field performance and compatibility of a traditional aft fuselage with the established infrastructure and procedures for loading, unloading and airdropping cargo and troops.

With a pair of ultra-high-bypass turbofans mounted above the trailing edge of the wing, the HWB is designed to carry all of the outsize cargo now airlifted by the Lockheed C-5 while burning 70% less fuel than the Boeing C-17.

While the NTF tests validated the high-speed cruise efficiency of the configuration, including a 5% improvement for over-wing nacelles versus the traditional location under the wing leading edge, the low-speed tests at Lockheed were focused on gathering stability and control data to confirm the configuration’s expected handing qualities.

“What really sets this apart is we get the performance of an unconventional configuration with conventional control effectors,” says Rick Hooker, Lockheed Martin Skunk Works HWB program manager. “It flies just like a tube-and-wing aircraft, using aileron, elevator and rudder.” Tailless flying-wing aircraft require unconventional control effectors for safe low-speed handling.

Where the half-span HWB tested in the NTF was a heavy metal model designed to withstand loads up to 12,000 lb. at transonic speeds, the low-speed model is the complete aircraft—about 10-ft. in span, but weighing just 45 lb.—so it can be flown later. “The light weight was a big challenge,” he says, as it had to carry more than 500 lb. of lift. “The hard part was getting it to survive the wind tunnel.”

Over a period of three weeks, the HWB was evaluated in the Marietta tunnel at speeds typically below 150 mph. The model was tested in cruise configuration to evaluate control-surface effectiveness and in high-lift configuration, with slats and flaps extended. Some low-speed high-lift testing was conducted in the NTF, and Lockheed was looking to confirm that data in the Marietta tests. “The results are in line with pre-test CFD, and we have good correlation with low-speed data out of the NTF,” says Hooker.

Where the NTF model had a flow-through engine nacelle, the low-speed model has a pair of electric ducted fans simulating the over-wing turbofans. This allowed Lockheed to validate the powered-lift benefit predicted to result from the additional airflow over the wing entrained by the engines.

“We tested the model at a range of power settings and control-surface deflections to see the impact on stability and control, and confirm the handling qualities,” Hooker says. “We also tested it in high-lift mode with slats and flaps and powered nacelles and confirmed the powered-lift benefit.”

The model’s 10-lb.-thrust ducted fans were not exactly the same scale size as the HWB’s large-diameter turbofan engines, but the jets produced were equivalent, enabling Lockheed to validate the powered-lift benefit predicted by CFD “with enough confidence to apply it to the full-size aircraft,” he says.

The low-speed model, designed by Lockheed and built by Empirical Systems Aerospace, will be refurbished and flown as a remotely piloted aircraft “sometime this year,” says Hooker. The goal is to assess handling qualities in cruise mode, but the model will be equipped with an air-data probe. “We know the thrust the fans produce, so we’ll be able to figure out the aircraft’s drag and get a full performance database to compare with the wind tunnel and CFD,” he says.

Lockheed is pursuing the HWB concept with funding support from the U.S. Air Force Research Laboratory (AFRL) under its Revolutionary Configurations for Energy Efficiency program, which ends in 2017. The company will complete a study for AFRL of a manned HWB demonstrator this fall, he says. A commercialization study for NASA, looking at a freighter variant, will finish around the same time.

NASA has unveiled budget plans to fly a 50%-scale hybrid wing body demonstrator after 2020 as the second in a proposed series of large-scale X-planes. To date, the agency’s definition of HWB has been synonymous with Boeing’s Blended Wing Body configuration, but Lockheed plans to propose its HWB concept, and NASA says selection of the X-plane will be an open competition. “We do qualify to play in the HWB plans, and are working with NASA to make sure that we do,” says Hooker.

Source URL: http://aviationweek.com/future-leaders/next-lockheed-low-speed-hwb-airlifter-flight

![AIAA Propulsion Energy 2014 on Livestream.flv_snapshot_00.32.13_[2014.07.31_12.00.30].jpg](/data/attachments/98/98906-60ed81944bcc869eac0dde8f01775380.jpg)