P&W to develop novel hydrogen engine in US government-backed project

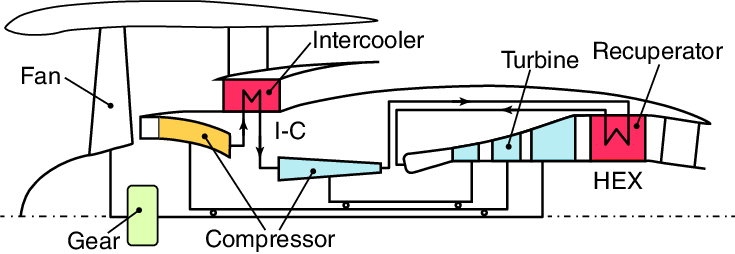

Pratt & Whitney is to develop a novel hydrogen-burning engine that will cut carbon dioxide emissions to zero, slash nitrous oxide emissions by 80% and reduce fuel consumption for next-generation single-aisles by 35%.

A P&W project, hydrogen burning, steam injected and intercooled engine envisioned to increase efficiency (single aisles 35%), evade (at least direct) carbon dioxide emissions entirely and cut nitrous oxide emissions (80%). Not an incremental approach but aiming for something greater then. Water vapor at least partially recovered - could we call this a hybrid steam engine? US DoE funding quite modest at this stage, only $3.8 million but it's a start anyway.