Forest Green

ACCESS: Above Top Secret

- Joined

- 11 June 2019

- Messages

- 5,230

- Reaction score

- 6,905

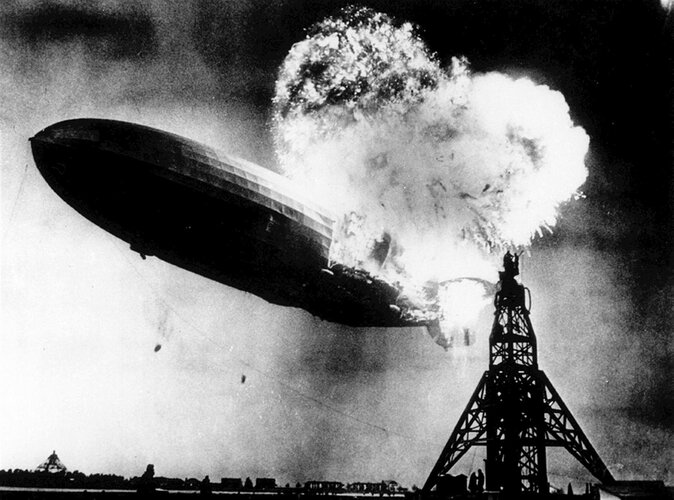

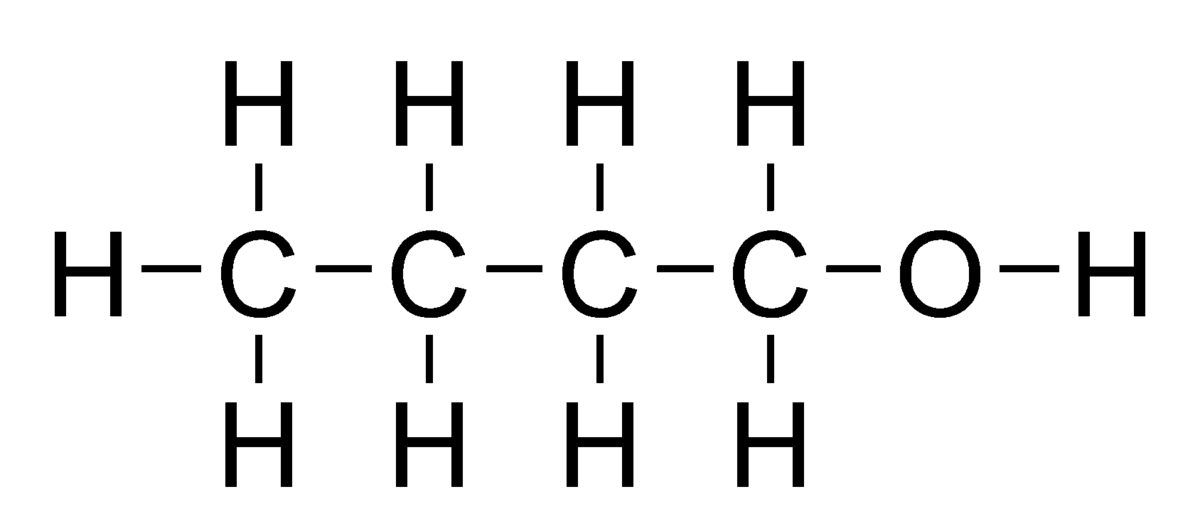

Safety with the engines was never the issue. It is the logistics involved with H2With modern technology that they never had back in the past I am certain that Hydrogen engines that we have now will be much safer.

I am all for Hydrogen powered aircraft engines especially when they have just discovered green hydrogen in the north of France under ground and there seems to be enough to last for a good number of years, it would be better than trying to manufacure hydrogen with all the problems that it currently has.

If LH2 becomes the predominant aviation fuel commercial air travel will only be affordable by a tiny minority of the wealthy people. The laws of physics mean that simple frequent/routine maintenance operations, normally taking minutes or hours will take days…… who pays for that?

H2 is only an energy store, the energy contained still has to be fabricated….. from what I can tell most costing models ignore this inconvenience. The U.K. is building a massive 40 billion $ nuclear station. If London Heathrow used LH2 produced from nuke it would need three to four of these say 150 billion before operating cost and the first 1Kg of LH2 has been dispatched. Who pays for this?

And the sad reality is H2 inherently leaked from even this operation will cause as much global warming today’s civil aviation operations;- its nearly impossible to stop it leaking.

Not really. It had nothing to do with "marketing". It was technology - batteries. They didn't have the storage capacity. Plus the micro electronics to monitor them.And we all know what happened to the EVs after they were invented 140 years ago the rival combustion engine took over and sadly replaced them, things could have been very different if the EV had been properly marketed as an alternative then things would have been very different today.

Currently, yes, SAF is (expletives deleted) expensive. Get more people making it to increase production volumes means you can get economies of scale involved. Process flow chemistry instead of step by step.Reminds me of a recent news story about supposedly non-petroleum-based synthetic jet fuels, where some company was advertising it as the "future" for their airline...but the costs involved were going to cause ticket prices to go up by a factor of 10 (minimum) compared to regular airline tickets for the same destinations, because the fuel is so expensive to manufacture.

Very little deep frying actually happens in the home, and even less now with air fryingEconomies of scale can run into issues, however, if there are a lack of materials to use.

I see that SAF can be made with used cooking oil. Great, sure, we make a lot of fried food in the world...but how much of the oil used in cooking -- not just in restaurants, but in homes -- is actually recycled? How much will it cost to collect the cooking oil that is currently not recycled, which then will be incorporated into the cost of SAF?

We are talking US households, ones that can participate in recycling.That would depend on the household, as the current per-household usage of air fryers is still extremely low (apparently 0.03 worldwide)...& I would imagine that would probably vary regionally (for example, in countries with less efficient or less reliable electrical grids, the market penetration of air fryers is going to remain extremely low, but frying over gas or wood flames would still be available). You're also assuming a binary of "everything is deep-fried" vs. "everything is air-fried without oil". There's also the pan-fried option -- which is how you prepare, say, bell peppers & onions for use with fajitas, pan-fried chicken, etc.

Then there's also the other biofuels that will be fighting for that used cooking oil. Every biofuel wants used cooking oil, & I doubt the biodiesel makers are going to give it up to help make SAF costs go down.

You do not have to use biodiesel processes to make SAF. In fact, I'm pretty sure you DON'T WANT to use biodiesel processes, due to the high gel temperatures that biodiesel has. Let the ground transportation folks use biodiesel.Economies of scale can run into issues, however, if there are a lack of materials to use.

I see that SAF can be made with used cooking oil. Great, sure, we make a lot of fried food in the world...but how much of the oil used in cooking -- not just in restaurants, but in homes -- is actually recycled? How much will it cost to collect the cooking oil that is currently not recycled, which then will be incorporated into the cost of SAF?

As for making SAF from plants...I'm not sure about the long-term effectiveness of turning plants (which turn CO2 into O2) into jet fuel to lessen the amount of CO2 in the atmosphere. I suspect that you'll reduce more CO2 in the atmosphere by planting more plants & trees than by substituting plant-based jet fuel for petroleum-based jet fuel...

Wrong. Pan frying doesn't require large amounts of oil (more than a cup)Nor is olive oil the only oil used -- some people don't like the taste (and yes, there is a difference in canola oil vs. vegetable oil vs. olive oil vs. butter) -- & the amount of oil used will vary from person to person, so a blanket statement of "no oil will remain" is disingenous. And again, just because oil usage is low in US households doesn't mean that oil usage is also low in other countries. Some countries treat cooking oil as its own food group

Again.SAF isn't being produced exclusively in the US...or did you not realize that? The US is also not the only country that has people flying on airliners, nor are they the only destinations that people fly to. Of the top 5 companies currently producing SAF, #3 through 5 are not located in the US -- Oriental Energy Co. (Singapore & Indonesia), Alfanar Group (Teesside, UK), & UPM Biofuels (Finland). I seriously doubt any of those companies is importing their used cooking oil from US sources. Nor is the US the only nation that engages in recycling of used cooking oil -- a simple Google search found this company that has offices in multiple European nations as well as Egypt, for exampel.

Nor is olive oil the only oil used -- some people don't like the taste (and yes, there is a difference in canola oil vs. vegetable oil vs. olive oil vs. butter) -- & the amount of oil used will vary from person to person, so a blanket statement of "no oil will remain" is disingenous. And again, just because oil usage is low in US households doesn't mean that oil usage is also low in other countries. Some countries treat cooking oil as its own food group.

And I see you also completely ignored the part where I pointed out that SAF isn't happening in a vacuum, with other biofuels competing for the same limited resource. When demand exceeds supply, you don't get "economies of scale", you get higher prices for the oil...which means higher prices for SAF. Airline fuel usage is at most maybe one percent of that used by the trucking industry, so the demand from non-airlines is going to be much higher than that of the airlines...which either means a) their supplies of SAF will be limited (probably keeping prices high), or b) they'll have to pay a premium to outbid the other users demanding used cooking oil for their biofuels (which, again, will keep SAF prices higher).

Different processes use different raw materials. I'm talking about Fischer-Tropsch process, Bergius process, and others. Not, say again NOT BIODIESEL!I never said they were using the same process. I said they use the same raw material. Just like you can't fill your tractor-trailer's tank with jet fuel, but both diesel & jet fuel are currently both produced from petroleum: same raw material source, different products after refining.

Just like you can't fill your tractor-trailer's tank with jet fuel,

WRONG! They all use different raw materials!Again, I never said "put biodiesel in jet engines". What I said was that both fuels use the same raw materials.

If you have two companies that both use a specific kind of timber, with one making furniture out of it & the other making homes, they're making two separate products but from the same raw material....& if the supply of the resource is limited and isn't enough to meet the demands from both manufacturers, then the price for the supply will go up, as will the products, & neither manufacturer will be able to make as many items as they want...unless one of them is willing to pay even more money for exclusive access to the limited supply of that critical resource.

That's basic business, economics, & accounting, all rolled into one. Biofuels -- whether SAF, biodiesel, or other types -- all need the same raw materials, regardless of what process is used.

Right. But look at WHAT BIOMASS is being used. "Biomass" is not only vegetable oil.If the F-T process doesn't use biomass, the resulting fuel emits MORE CO2 than petroleum-based fuels...which would go completely against the whole purpose of producing SAF. It's ONLY when the F-T process incorporates biomass that the resulting SAF emits lower CO2 levels when burned.

It's also why non-biomass feedstocks are NOT the primary sources for SAF.

IATA (International Air Travel Authority) statement regarding SAF

Funny enough, the "Diesel Exhaust Fluid" used to help control NOx emissions is urea, which breaks down to ammonia under heat to do the actual work.100% agree about Ammonia. With in-flight cracking of a few hydrogen to energize the fuel mix. Ammonia is relatively easy to store but only has half the energy of kerosene. And hydrogen is the exact opposite. 2.7 times more energy than kerosene, but awful to store - temperature sucks, density sucks, explosivity sucks, leakage sucks... it sucks at every storage level !

How about methanol ? same major issue as ammonia, that is only half the enrgy of kerosene. Plus it has carbon, unlike ammonia. Then again, ammonia's nitrogen leds to NOx, which can be a major health issue if no handled the right way.