How about details instead of cryptic posts?I am in favour of any technological development, without ideological conditions, but before buying an electric car I advise you to read the small print of the contract. When in doubt, ask any Hong Kong resident for the true final price.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Electric vehicle discussion

- Thread starter edwest4

- Start date

Well, I also find the god of frustration quite cryptic, but there are concepts that cannot be explained without violating some rules and that close the thread.How about details instead of cryptic posts?

Someone's avatar is a different matter than a comment posted in the thread proper as you should well know. It seems like you are just offering opinions without any evidence to back up.

Someone's avatar is a different matter than a comment posted in the thread proper as you should well know. It seems like you are just offering opinions without any evidence to back up.

Well, I think there is plenty of evidence, on the internet you can find thousands, although you may prefer photos of panda bears.

I wouldn't buy an electric car from people who do this with freedom.

https://www.amnesty.org/en/latest/p...ngs-and-torture-in-police-detention-revealed/

https://www.bbc.com/news/articles/c888jnvq4x4o

https://www.state.gov/bureau-of-eas...ases/2024/03/2024-hong-kong-policy-act-report

https://hk.usconsulate.gov/n-2024032901/

https://www.bde.es/f/webbe/SES/Secc...oletinEconomico/24/T4/Files/be2404-art03e.pdf

https://think.ing.com/articles/eus-final-decision-on-tariffs-for-evs-from-china/

https://merics.org/en/comment/merics-forum-chinese-ev-investments-europe

Attachments

Last edited:

Well if there is plenty of evidence, why was it so hard for you to do so in the first place?Well, I think there is plenty of evidence, on the internet you can find thousands,

Enough with the disrespect!although you may prefer photos of panda bears.

It might surprise you but I refuse to buy an electric car from China as well...but for different reasons.I wouldn't buy an electric car from people who do this with freedom.

0cu0

I rlleay shloud cahnge my peroasnl txet

- Joined

- 14 January 2025

- Messages

- 33

- Reaction score

- 38

meanwhile in germany : )

timesofmalta.com

timesofmalta.com

Watch: ‘Heil Tesla’ projected onto German car factory

Elon Musk's gesture at Trump inauguration drew comparisons to Nazi salutes

Last edited:

Let each one act according to his conscience or his particular interests and live with the consequences.Well if there is plenty of evidence, why was it so hard for you to do so in the first place?

Enough with the disrespect!

It might surprise you but I refuse to buy an electric car from China as well...but for different reasons.

The Real Cost of Diamonds | Danielle Rousseau

Last edited:

An interesting case for future regulations and developments: the unexpected consequences of mass EV fire on public safety.*

www.nbclosangeles.com

www.nbclosangeles.com

*for me it will be also a hazard for military logistics in case of large conflicts where population tends to flee combat zones... What happens when side roads are turned on hundred of miles into minefields by burning/wrecked vehicles and directed energy triggering?

‘Unprecedented' number of lithium ion batteries complicates LA wildfires cleanup

What authorities described as one of the largest lithium-ion battery cleanups ever is underway in Los Angeles County neighborhoods destroyed by the Eaton and Palisades fires.

www.nbclosangeles.com

www.nbclosangeles.com

*for me it will be also a hazard for military logistics in case of large conflicts where population tends to flee combat zones... What happens when side roads are turned on hundred of miles into minefields by burning/wrecked vehicles and directed energy triggering?

Power train design and other news

techxplore.com

techxplore.com

This AI system automatically optimizes the entire powertrain—from the power electronics to the electric machine through to the transmission—in line with the manufacturer's technical requirements, taking into account targets such as production costs, efficiency and package space requirements in the vehicle.

The OPED (Optimization of Electric Drives) software solution was developed at TU Graz and is the result of almost ten years of research. It is already being used successfully by a renowned Austrian automotive supplier.

techxplore.com

techxplore.com

techxplore.com

techxplore.com

techxplore.com

techxplore.com

techxplore.com

techxplore.com

E-mobility: AI system accelerates the development of powertrains

The development of vehicle components is a lengthy and therefore very costly process. Researchers at Graz University of Technology (TU Graz) have developed a method that can shorten the development phase of the powertrain of battery electric vehicles by several months.

This AI system automatically optimizes the entire powertrain—from the power electronics to the electric machine through to the transmission—in line with the manufacturer's technical requirements, taking into account targets such as production costs, efficiency and package space requirements in the vehicle.

The OPED (Optimization of Electric Drives) software solution was developed at TU Graz and is the result of almost ten years of research. It is already being used successfully by a renowned Austrian automotive supplier.

A scientific approach based on traffic patterns and commuter mobility can optimize bike lane planning

When it comes to opinions about bike lanes, few of us are stuck in neutral. Love them or hate them though, new research says a dose of scientific rationality can help locate them in the best places. Congestion is minimized while more people ditch the car in favor of emissions-free, two-wheeled...

Researchers develop metric to measure US gaps in electric vehicle charging

Although electric vehicles (EVs) present a considerable opportunity to lower greenhouse gas emissions, EVs currently only account for 1% of vehicles on the road in the U.S. One reason consumers have reported hesitation in purchasing EVs is charging anxiety, or concerns about losing power without...

How simple prompts can make partially automated cars safer

A new study finds that prompts do a good job of getting drivers to engage with their environment and take over control of the vehicle when necessary while using partially automated driving systems—with one exception. If drivers are deeply distracted, these system-generated prompts have little or...

Researchers develop metric to measure US gaps in electric vehicle charging

Although electric vehicles (EVs) present a considerable opportunity to lower greenhouse gas emissions, EVs currently only account for 1% of vehicles on the road in the U.S. One reason consumers have reported hesitation in purchasing EVs is charging anxiety, or concerns about losing power without...

Scott Kenny

ACCESS: USAP

- Joined

- 15 May 2023

- Messages

- 11,628

- Reaction score

- 14,305

And no mention of ease of repair...This AI system automatically optimizes the entire powertrain—from the power electronics to the electric machine through to the transmission—in line with the manufacturer's technical requirements, taking into account targets such as production costs, efficiency and package space requirements in the vehicle.

F-14ATomcat

ACCESS: Secret

- Joined

- 26 May 2024

- Messages

- 454

- Reaction score

- 847

Mexican electric cars

VEKSTAR-Bimbo cars

View: https://www.youtube.com/watch?time_continue=3&v=oq5bmwUkMVQ&embeds_referring_euri=https%3A%2F%2Fwww.google.com%2Fsearch%3Fsca_esv%3Dc74cae123ea38640%26hl%3Den%26sxsrf%3DAHTn8zrAIWiNAtokQIGIudgzoKvqamQoDw%3A1738377784705%26q%3Dvekstar%2Bca&source_ve_path=Mjg2NjY

VEKSTAR-Bimbo cars

F-14ATomcat

ACCESS: Secret

- Joined

- 26 May 2024

- Messages

- 454

- Reaction score

- 847

The Taruk project, the result of collaboration between the National Council of Humanities, Sciences and Technologies (Conahcyt), the companies Dina and Megaflux, and the UNAM Engineering Institute, represents a significant advance in public transport in Mexico. This electric bus, designed and manufactured in the country, is promoting sustainable mobility in Mexico City.

During the presentation of the bus at the Antiguo Palacio de Minería, María Elena Álvarez-Buylla, general director of Conahcyt, highlighted that ‘Taruk’ symbolizes a “historic achievement”, since it is the result of collaboration between the government, industry and the academic sector. The name ‘Taruk’, which in the Yaqui language means “road runner”, reflects its ability to travel long distances efficiently. The vehicle uses lithium batteries that require only four hours of charging to travel up to 200 kilometers.

Manufacturing and technology

Roberto Gottfried, co-founder of MF Vehículos Eléctricos, explained that approximately 70% of the components of ‘Taruk’ are manufactured domestically, while the remaining 30%, including lithium cells and power electronics, must still be imported due to the lack of local production. Even though the design is completely Mexican, some of these technological elements are not manufactured in the country.

Operation in Mexico City

Starting this Tuesday, ‘Taruk’ began operating on Route 46 in Mexico City as part of a three-month pilot test. The bus has capacity for 69 passengers and will cover a 22-kilometer route with 39 stops, covering the municipalities of Iztacalco, Iztapalapa and Tláhuac. This route will connect Santa Catarina with the Central de Abasto, one of the busiest areas of the city.

'Taruk': El autobús eléctrico de DINA y Megaflux ya recorre las calles de la Cdmx - Pasajero7

#Taruk simboliza un logro, ya que es fruto de la colaboración entre el gobierno, la industria y el sector académico. El #AutobúsElectrico.

F-14ATomcat

ACCESS: Secret

- Joined

- 26 May 2024

- Messages

- 454

- Reaction score

- 847

The Mexican automotive industry is taking a bold step towards sustainability with Olinia, a 100% electric vehicle manufacturer designed and manufactured in Mexico. Recently presented by President Claudia Sheinbaum, this project promises to change the way we move, offering accessible and sustainable options to meet urban mobility needs; so, if you are looking for an alternative to the motorcycle or the traditional taxi, this is for you!

Sheinbaum highlighted the symbolism behind the name Olinia, which in Nahuatl means “to move.” This project seeks to position itself as a clean and efficient mobility option for a country where more than 70% of the population lives in urban areas and where daily trips are usually less than 30 kilometers.

The development of Olinia includes three categories of electric vehicles, specifically designed to meet the most urgent transportation needs in Mexican cities:

Personal Mobility: An alternative for motorcycle users, offering greater safety and sustainability.

Neighborhood Mobility: Small vehicles ideal for local taxis or motorcycle taxis, optimizing comfort and operating costs.

Last Mile Deliveries: Designed for logistics companies and home deliveries, perfect for short distances.

“We want to offer practical and economical solutions that transform the way people and companies move around our cities,” said Sheinbaum in her speech.

How much will Olinia cost?

One of the most attractive aspects of Olinia is its price. It is estimated that the vehicles will have an initial cost between $90,000 and $150,000 pesos, similar to that of a mid-range motorcycle. This will be possible thanks to a modular platform that will reduce production costs and offer competitive prices.

For his part, Fernando Díaz, a mobility engineer at the National Technological Institute of Mexico, explained:

“Modularity not only reduces costs, but also facilitates future technological updates. We want Olinia to be an accessible investment for everyone.”

Academic collaboration and public investment

The development of Olinia is led by specialists from the National Polytechnic Institute (IPN) and the National Technological Institute of Mexico, who have received an initial budget of 25 million pesos granted by the Secretariat of Science, Humanities, Technology and Innovation.

In addition, the locations of the assembly plants are being considered, with Puebla and Sonora as the main options due to their industrial and logistical experience. José Luis Ramírez, representative of the automotive sector in Puebla, stated: “This project not only promotes electric mobility, but also generates jobs and local economic development.”

Official presentation at the 2026 World Cup

The first Olinia models are expected to be presented at a spectacular event at the Azteca Stadium, during the 2026 World Cup. This strategy aims to capture both national and international attention, attracting future public and private investments.

In the words of Claudia Sheinbaum: “The World Cup will be the ideal platform to show the world that Mexico is ready to lead in innovation and sustainability.”

The compact electric vehicle market is booming. In Asia, for example, more than 1.3 million units were sold in 2023, demonstrating the viability of this segment. Mexico, with a growing need for sustainable options, has the potential to replicate this success.

Olinia is not just a vehicle, it is a project that reflects an unprecedented collaboration between the government, academia and eventually, the private sector. This comprehensive approach seeks not only to improve mobility, but also to reduce emissions and promote a better quality of life for Mexicans.

With affordable prices, functional designs and a clear commitment to the environment, Olinia could mark a before and after in the national automotive industry.

metronoticias.mx

metronoticias.mx

Sheinbaum highlighted the symbolism behind the name Olinia, which in Nahuatl means “to move.” This project seeks to position itself as a clean and efficient mobility option for a country where more than 70% of the population lives in urban areas and where daily trips are usually less than 30 kilometers.

The development of Olinia includes three categories of electric vehicles, specifically designed to meet the most urgent transportation needs in Mexican cities:

Personal Mobility: An alternative for motorcycle users, offering greater safety and sustainability.

Neighborhood Mobility: Small vehicles ideal for local taxis or motorcycle taxis, optimizing comfort and operating costs.

Last Mile Deliveries: Designed for logistics companies and home deliveries, perfect for short distances.

“We want to offer practical and economical solutions that transform the way people and companies move around our cities,” said Sheinbaum in her speech.

How much will Olinia cost?

One of the most attractive aspects of Olinia is its price. It is estimated that the vehicles will have an initial cost between $90,000 and $150,000 pesos, similar to that of a mid-range motorcycle. This will be possible thanks to a modular platform that will reduce production costs and offer competitive prices.

For his part, Fernando Díaz, a mobility engineer at the National Technological Institute of Mexico, explained:

“Modularity not only reduces costs, but also facilitates future technological updates. We want Olinia to be an accessible investment for everyone.”

Academic collaboration and public investment

The development of Olinia is led by specialists from the National Polytechnic Institute (IPN) and the National Technological Institute of Mexico, who have received an initial budget of 25 million pesos granted by the Secretariat of Science, Humanities, Technology and Innovation.

In addition, the locations of the assembly plants are being considered, with Puebla and Sonora as the main options due to their industrial and logistical experience. José Luis Ramírez, representative of the automotive sector in Puebla, stated: “This project not only promotes electric mobility, but also generates jobs and local economic development.”

Official presentation at the 2026 World Cup

The first Olinia models are expected to be presented at a spectacular event at the Azteca Stadium, during the 2026 World Cup. This strategy aims to capture both national and international attention, attracting future public and private investments.

In the words of Claudia Sheinbaum: “The World Cup will be the ideal platform to show the world that Mexico is ready to lead in innovation and sustainability.”

The compact electric vehicle market is booming. In Asia, for example, more than 1.3 million units were sold in 2023, demonstrating the viability of this segment. Mexico, with a growing need for sustainable options, has the potential to replicate this success.

Olinia is not just a vehicle, it is a project that reflects an unprecedented collaboration between the government, academia and eventually, the private sector. This comprehensive approach seeks not only to improve mobility, but also to reduce emissions and promote a better quality of life for Mexicans.

With affordable prices, functional designs and a clear commitment to the environment, Olinia could mark a before and after in the national automotive industry.

Olinia: Auto eléctrico mexicano que podría revolucionar la movilidad urbana - Metro Noticias

La industria automotriz mexicana está dando un paso audaz hacia la sostenibilidad con Olinia, una

F-14ATomcat

ACCESS: Secret

- Joined

- 26 May 2024

- Messages

- 454

- Reaction score

- 847

With the purpose of offering more and better mobility options, in terms of costs and the environment, the Mexican company Vehículos Eléctricos Corporativos (VEC), together with the Secretariat of Science, Technology and Innovation of Mexico City (Seciti) and the Universidad Autónoma Metropolitana (UAM) Azcapotzalco campus, presented a completely electric light-duty vehicle.

View: https://www.youtube.com/watch?v=dcxp_8tkaX4

Thinking of the businessman of tomorrow with practicality, effectiveness and efficiency, our objective is to make your company transport merchandise and goods at a low cost and with unique practicality, this can only be offered to you by LM&TH AUTOMOVILES.

• City car 100% Mexican and %100 electric.

• 3 Seats + High volume trunk.

• Maximum speed 70 km/hr.

• Cruising speed 40 km/hr.

• Latest generation AC 60 KW motors.

• Aluminum-magnesium 6061 and 6063 chassis and suspension.

• Autonomy more than 200 km / battery charge.

• Charging Lithium or lead acid batteries deep cycle – 5 to 6 hours.

• 2 options: 63kw/15kw AC Brushless electric motor.

• Independent and adjustable suspension with type “A” forks.

• Efic-all technology for design with aerospace programs.

• Interbodies technology to change models with the same chassis.

• Digital technology on “Touch” screen for vehicle control.

• Dimensions: 3.1mts x 1.7mts x 1.5mts.

• Weight approx 600kg (without crew).

• Fully configurable and customizable.

• 8-year warranty on mechanical auto parts.

View: https://www.youtube.com/watch?v=iQl3uKBzeHM&t=3s

Thinking of the businessman of tomorrow with practicality, effectiveness and efficiency, our objective is to make your company transport merchandise and goods at a low cost and with unique practicality, this can only be offered to you by LM&TH AUTOMOVILES.

• City car 100% Mexican and %100 electric.

• 3 Seats + High volume trunk.

• Maximum speed 70 km/hr.

• Cruising speed 40 km/hr.

• Latest generation AC 60 KW motors.

• Aluminum-magnesium 6061 and 6063 chassis and suspension.

• Autonomy more than 200 km / battery charge.

• Charging Lithium or lead acid batteries deep cycle – 5 to 6 hours.

• 2 options: 63kw/15kw AC Brushless electric motor.

• Independent and adjustable suspension with type “A” forks.

• Efic-all technology for design with aerospace programs.

• Interbodies technology to change models with the same chassis.

• Digital technology on “Touch” screen for vehicle control.

• Dimensions: 3.1mts x 1.7mts x 1.5mts.

• Weight approx 600kg (without crew).

• Fully configurable and customizable.

• 8-year warranty on mechanical auto parts.

Last edited:

True--I also support right-to-repair.And no mention of ease of repair...

I wish I had Elon's money...I would have mechanics design a car.

Engine can still supply electrical power to rear wheels even if the transmission is broken. Several batteries to limp home if the engine quits.

No aerodynamics...long hood, long trunk--real bumpers.

F-14ATomcat

ACCESS: Secret

- Joined

- 26 May 2024

- Messages

- 454

- Reaction score

- 847

The Jalisco-based company Carrocerías Hermanos Becerra S.A. de C.V. (BECCAR) presented the first 100% electric bus manufactured in Mexico, a sustainable and zero-emission alternative for urban transport.

The E-Urviabus-Volt, assembled by Mexican engineers at the BECCAR plant located in the municipality of Zapotlanejo, Jalisco, is a low-floor unit with an electric motor with a maximum capacity of 295 kW, manufactured under international safety standards.

Fundada en 1984, BECCAR es una empresa mexicana dedicada a la fabricación de carrocerías para autobuses urbanos y producción de unidades para el segmento de transporte público. Entre sus principales clientes destacan fabricantes de motrices tales como Mercedes Benz, Scania, Volvo, Man, Volkswagen e International.

View: https://www.youtube.com/watch?v=48rhngI1gbQ

View: https://www.youtube.com/watch?v=CVeznXAaX8U

The E-Urviabus-Volt, assembled by Mexican engineers at the BECCAR plant located in the municipality of Zapotlanejo, Jalisco, is a low-floor unit with an electric motor with a maximum capacity of 295 kW, manufactured under international safety standards.

Fundada en 1984, BECCAR es una empresa mexicana dedicada a la fabricación de carrocerías para autobuses urbanos y producción de unidades para el segmento de transporte público. Entre sus principales clientes destacan fabricantes de motrices tales como Mercedes Benz, Scania, Volvo, Man, Volkswagen e International.

F-14ATomcat

ACCESS: Secret

- Joined

- 26 May 2024

- Messages

- 454

- Reaction score

- 847

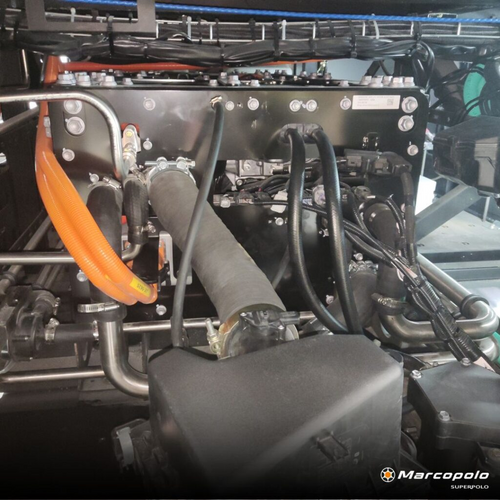

In our video, we present the exterior, passenger area, driver's seat and exclusive images of the factory, thanks to a kind invitation from Marcopolo Superpolo, which has developed a minibus for 50 passengers, of which it will deliver 193 to the town of Fontibón, west of Bogotá.

These are the new colombian Marcopolo electric buses for Transmilenio

F-14ATomcat

ACCESS: Secret

- Joined

- 26 May 2024

- Messages

- 454

- Reaction score

- 847

Launched in late 2013, the e-Bus is the first Brazilian electric bus powered 100% by batteries.

The e-Bus is the result of a partnership with Brazilian companies. The vehicle features electric traction and integration technology from Eletra, a Caio e-Millennium body, WEG batteries and electric motors – all Brazilian companies – and a Mercedes-Benz and Scania chassis, manufactured in São Bernardo do Campo (SP).

www.eletrabus.com.br

View: https://www.youtube.com/watch?v=N_7rVBhtV4U

www.eletrabus.com.br

View: https://www.youtube.com/watch?v=N_7rVBhtV4U

The e-Bus is the result of a partnership with Brazilian companies. The vehicle features electric traction and integration technology from Eletra, a Caio e-Millennium body, WEG batteries and electric motors – all Brazilian companies – and a Mercedes-Benz and Scania chassis, manufactured in São Bernardo do Campo (SP).

Elétrico – Eletra

Buses lend themselves to alternative forms of propulsion...ample room for flat batteries between frame and floorboard.

www.comsol.com

www.comsol.com

eBook: Electric Vehicle R&D

Find inspiration from engineers, scientists, and researchers in the EV field who use simulation to innovate. Download the free ebook here.

Last edited:

F-14ATomcat

ACCESS: Secret

- Joined

- 26 May 2024

- Messages

- 454

- Reaction score

- 847

Buses are a better option than cars, first they reduce CO2 emissions per passenger, second they require less investment than the large manufacture of smaller sized cars, and in Latin America many people can not buy even an ICE car, so electric vehicles make more sense if they are Buses, add the less Lithium used in their production.Buses lend themselves to alternative forms of propulsion...ample room for flat batteries between frame and floorboard.

The other advantage you require less recharging station, so for poor countries like the ones in Latin AMerica buses are a better option

The president walked to the Eletra factory and spoke with factory workers and leaders. In his speech, the president highlighted the importance of the Brazilian industry and production for the national market.

Last edited:

F-14ATomcat

ACCESS: Secret

- Joined

- 26 May 2024

- Messages

- 454

- Reaction score

- 847

Learn in detail how this vehicle, manufactured in Colombia by Superpolo, was conceived. Also, learn about how hydrogen is produced and its advantages over traditional fossil fuels.

View: https://www.youtube.com/watch?v=02QykspyGio&embeds_referring_euri=https%3A%2F%2Fdefenceforumbharat.com%2F&source_ve_path=OTY3MTQ

Today marks a milestone in the history of our country and Latin America. We are proud of our team that built and made a project a reality that years ago was just a dream.

Our unit has a range of 450 km (in a single charge) and can reach up to 90 km/h. In addition, it is budgeted to be integrated into the SITP (Integrated Public Transport System) in an 8-year test period. For approximately 3 years, our engineering team worked hard on every structural, technical and design detail to make this project an achievement for our country.

We will have the hydrogen station located in the Green Móvil yard, which is stipulated to feed approx. 15 units. This bus will begin to circulate in the city of Bogotá in the second half of 2023.

superpolo.com.co

superpolo.com.co

Today marks a milestone in the history of our country and Latin America. We are proud of our team that built and made a project a reality that years ago was just a dream.

Our unit has a range of 450 km (in a single charge) and can reach up to 90 km/h. In addition, it is budgeted to be integrated into the SITP (Integrated Public Transport System) in an 8-year test period. For approximately 3 years, our engineering team worked hard on every structural, technical and design detail to make this project an achievement for our country.

We will have the hydrogen station located in the Green Móvil yard, which is stipulated to feed approx. 15 units. This bus will begin to circulate in the city of Bogotá in the second half of 2023.

Nuestra unidad de Hidrógeno única en Latinoamérica - Marcopolo Superpolo

Nuestra unidad de Hidrógeno única en Latinoamérica resaltamos la dedicación del equipo de todo el equipo Marcopolo Superpolo en este proyecto

Last edited:

Scott Kenny

ACCESS: USAP

- Joined

- 15 May 2023

- Messages

- 11,628

- Reaction score

- 14,305

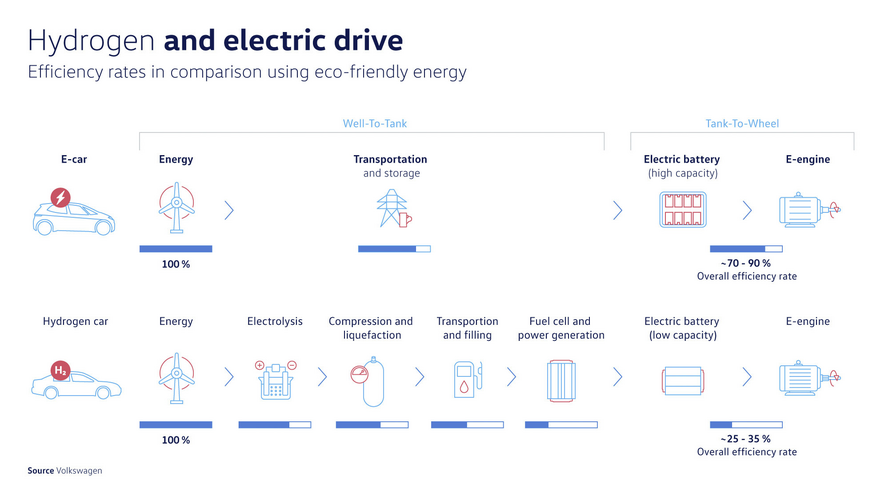

Hydrogen absolutely SUCKS for a moving vehicle fuel source, due to the extremely low density.Learn in detail how this vehicle, manufactured in Colombia by Superpolo, was conceived. Also, learn about how hydrogen is produced and its advantages over traditional fossil fuels.

You want to have 1kg of hydrogen onboard? well, if it's liquid hydrogen, you need 14 liters of volume inside the tank, plus however much insulation volume is needed to keep the stuff from boiling off. 1kg of diesel fuel is 1.25 liters.

Also, you cannot let a hydrogen-fueled vehicle sit. Say, long term airport parking? even if you parked with a full tank, any gaseous hydrogen will simply escape through solid steel and your fuel tank will be empty in a couple of days.

For stationary generators? sure, it's great. Except for the crazy broad explosive limits. hydrogen mixed with air at 40,000ppm (4%)? explosive. Hydrogen mixed with air at 750,000ppm (75%)? explosive. And everywhere inbetween.

F-14ATomcat

ACCESS: Secret

- Joined

- 26 May 2024

- Messages

- 454

- Reaction score

- 847

Hydrogen absolutely SUCKS for a moving vehicle fuel source, due to the extremely low density.

You want to have 1kg of hydrogen onboard? well, if it's liquid hydrogen, you need 14 liters of volume inside the tank, plus however much insulation volume is needed to keep the stuff from boiling off. 1kg of diesel fuel is 1.25 liters.

Also, you cannot let a hydrogen-fueled vehicle sit. Say, long term airport parking? even if you parked with a full tank, any gaseous hydrogen will simply escape through solid steel and your fuel tank will be empty in a couple of days.

For stationary generators? sure, it's great. Except for the crazy broad explosive limits. hydrogen mixed with air at 40,000ppm (4%)? explosive. Hydrogen mixed with air at 750,000ppm (75%)? explosive. And everywhere inbetween.

Fuel Cell Electric Vehicles

Fuel cell electric vehicles (FCEVs) are powered by hydrogen. They are more efficient than conventional internal combustion engine vehicles and produce no harmful tailpipe emissions—they only emit water vapor and warm air. FCEVs and the hydrogen infrastructure to fuel them are in the early stages of implementation.

FCEVs use a propulsion system similar to that of electric vehicles, where energy stored as hydrogen is converted to electricity by the fuel cell. Unlike conventional internal combustion engine vehicles, these vehicles produce no harmful tailpipe emissions. Other benefits include increasing U.S. energy resiliency through diversity of energy sources and strengthening the economy.

FCEVs are fueled with pure hydrogen gas stored in a tank on the vehicle. Similar to conventional internal combustion engine vehicles, they can fuel in about 5 minutes and have a driving range of more than 300 miles.

The Marcopolo bus made in Colombia is the first one in Latin America

F-14ATomcat

ACCESS: Secret

- Joined

- 26 May 2024

- Messages

- 454

- Reaction score

- 847

A group of researchers from the Center for Research and Advanced Studies (Cinvestav), of the National Polytechnic Institute (IPN), developed a vehicle that runs on electric energy generated by hydrogen, which is friendly to the environment.

'Naya', whose name means clean in Zapotec, is a vehicle that can reach a speed of 35 kilometers per hour, weighs 180 kilos, can work continuously for up to an hour and a half and is easy to handle, as it has two pedals: the accelerator and the brake.

The research assistant of the Department of Chemistry, Andrés Rodríguez Castellanos, detailed in an interview that the vehicle has a power of 2.5 horsepower, an aluminum chassis and a fiberglass body so that it is light and can move.

This hybrid electric vehicle consists of an 800-liter hydrogen tank, a pump and valve system, a fuel cell and a battery bank, he added.

manufactura.mx

View: https://www.youtube.com/watch?v=LueKseWXEvM

manufactura.mx

View: https://www.youtube.com/watch?v=LueKseWXEvM

Learn about this electric vehicle and how it works. It was developed by INEEL and other institutions through the Energy Sustainability Fund - SENER - CONACYT and represents a contribution to sustainable transport technology.

'Naya', whose name means clean in Zapotec, is a vehicle that can reach a speed of 35 kilometers per hour, weighs 180 kilos, can work continuously for up to an hour and a half and is easy to handle, as it has two pedals: the accelerator and the brake.

The research assistant of the Department of Chemistry, Andrés Rodríguez Castellanos, detailed in an interview that the vehicle has a power of 2.5 horsepower, an aluminum chassis and a fiberglass body so that it is light and can move.

This hybrid electric vehicle consists of an 800-liter hydrogen tank, a pump and valve system, a fuel cell and a battery bank, he added.

Naya, un vehículo mexicano a base de hidrógeno

VIDEO. 'Naya' podría ser una solución en el DF: investigadores.

Learn about this electric vehicle and how it works. It was developed by INEEL and other institutions through the Energy Sustainability Fund - SENER - CONACYT and represents a contribution to sustainable transport technology.

F-14ATomcat

ACCESS: Secret

- Joined

- 26 May 2024

- Messages

- 454

- Reaction score

- 847

Zacua is the first Mexican brand of electric cars, designed exclusively for the city.

This Mexican company seeks to positively support society by contributing to making the country a greener place by producing automotive technologies that reduce our impact on the environment.

Zacua is the first Mexican brand of electric cars: designed, registered and developed in Mexico. It is part of Motores Limpios. S.A.P.I de C.V., a Mexican group dedicated to providing sustainable mobility solutions.

Zacua is zero emissions: it does not emit CO2, Greenhouse Gases or any other air polluting particle. It is a design car with limited production. We assemble our cars in a handcrafted process and in a special way under request for each client.

View: https://www.youtube.com/watch?v=m2w0ewzbcSE

This Mexican company seeks to positively support society by contributing to making the country a greener place by producing automotive technologies that reduce our impact on the environment.

Zacua is the first Mexican brand of electric cars: designed, registered and developed in Mexico. It is part of Motores Limpios. S.A.P.I de C.V., a Mexican group dedicated to providing sustainable mobility solutions.

Zacua is zero emissions: it does not emit CO2, Greenhouse Gases or any other air polluting particle. It is a design car with limited production. We assemble our cars in a handcrafted process and in a special way under request for each client.

- Joined

- 5 May 2007

- Messages

- 1,482

- Reaction score

- 2,858

The two fuels that are getting a lot of attention for shipping decarbonisation are methanol and ammonia, both through fuel cells. In fact, both are just means of transporting hydrogen around in a denser format - dealing with the otherwise superfluous carbon/oxygen/nitrogen is easier than trying to handle hydrogen directly.Hydrogen absolutely SUCKS for a moving vehicle fuel source, due to the extremely low density.

The advocates of either option will gladly tell you why the other is sheer madness.

Forest Green

ACCESS: Above Top Secret

- Joined

- 11 June 2019

- Messages

- 9,508

- Reaction score

- 17,402

alberchico

I really should change my personal text

- Joined

- 14 January 2014

- Messages

- 707

- Reaction score

- 1,513

Fiat Grande Panda Goes Back To Basics With Steelies And No Screen | Carscoops

The cheapest version of the Fiat Grande Panda looks more like a reincarnation of the original Panda from the '80s

It's great that Europe is finally getting affordable high quality locally made EV''s that can compete with the wave of incoming cheap Chinese imports.

F-14ATomcat

ACCESS: Secret

- Joined

- 26 May 2024

- Messages

- 454

- Reaction score

- 847

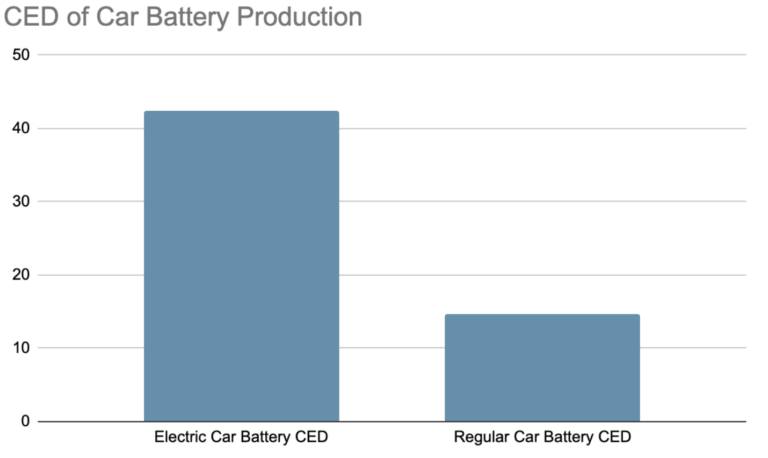

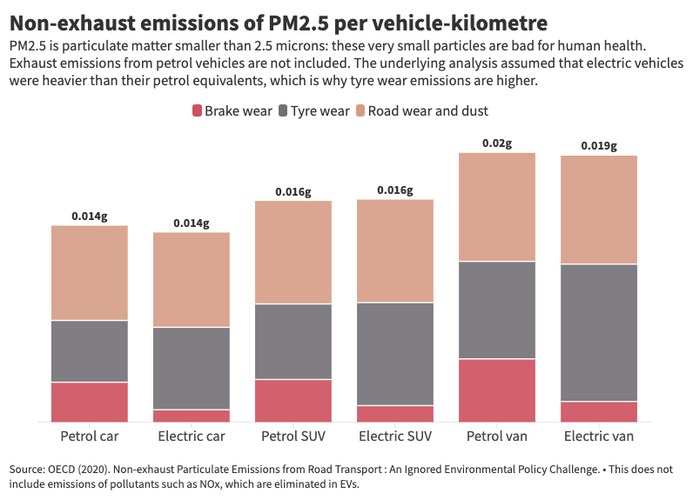

the main rule of environmental technology is all technologies pollute,

Lithium batteries pollute a lot, let us face it, mining the minerals is highly polluting.

About half of the U.S. population lives in areas where air pollution levels are high enough to negatively impact public health and the environment. Emissions from gasoline and diesel vehicles—such as nitrogen oxides, hydrocarbons, and particulate matter—are a major source of this pollution. While hydrogen internal combustion engines emit lower amounts of these pollutants than gasoline and diesel engines, hydrogen-powered fuel cell electric vehicles emit none of these harmful substances—only water (H2O) and warm air. The environmental and health benefits are also seen at the source of hydrogen production if the hydrogen is derived from low- or zero-emission sources, such as solar, wind, or nuclear energy or fossil fuels with advanced emission controls and carbon sequestration

. Electric vehicles, however, require lithium-ion batteries that have issues regarding greenhouse gas emissions during the mining and processing of the raw materials needed and the disposal of the batteries at the end of their life cycle. As more and more electric vehicles are sold, the problems inherent to mining and disposal increase

The production of lithium-ion batteries that power electric vehicles results in more carbon dioxide emissions than the production of gasoline-powered cars and their disposal at the end of their life cycle is a growing environmental concern as more and more electric vehicles populate the world’s roads. About 40 percent of the climate impact from the production of lithium-ion batteries comes from the mining and processing of the minerals needed. Mining and refining of battery materials, and manufacturing of the cells, modules and battery packs requires significant amounts of energy which generate greenhouse gases emissions. China, which dominates the world’s EV battery supply chain, gets almost 60 percent of its electricity from coal—a greenhouse gas-intensive fuel.

Environmental Impacts of Lithium-Ion Batteries - IER

The green transition is pushing electric vehicles upon the American public as it is believed that they are less greenhouse…

the point is the Colombian bus reduces emissions by passenger by being a bus and carrying lots of people and reduce the need for more batteries due to the hydrogen fuel cells.

It only carries 540 kg of hydrogen and has a range of 400km+

a EV with Lithium batteries will add lots of weight due to batteries and PM polluting just by weight

Do electric vehicles reduce air pollution?

Electric cars improve air quality compared to petrol and diesel cars, but they do not completely fix the problem.

Last edited:

Scott Kenny

ACCESS: USAP

- Joined

- 15 May 2023

- Messages

- 11,628

- Reaction score

- 14,305

All that is true.Fuel Cell Electric Vehicles

Fuel cell electric vehicles (FCEVs) are powered by hydrogen. They are more efficient than conventional internal combustion engine vehicles and produce no harmful tailpipe emissions—they only emit water vapor and warm air. FCEVs and the hydrogen infrastructure to fuel them are in the early stages of implementation.

FCEVs use a propulsion system similar to that of electric vehicles, where energy stored as hydrogen is converted to electricity by the fuel cell. Unlike conventional internal combustion engine vehicles, these vehicles produce no harmful tailpipe emissions. Other benefits include increasing U.S. energy resiliency through diversity of energy sources and strengthening the economy.

FCEVs are fueled with pure hydrogen gas stored in a tank on the vehicle. Similar to conventional internal combustion engine vehicles, they can fuel in about 5 minutes and have a driving range of more than 300 miles.

The Marcopolo bus made in Colombia is the first one in Latin America

And hydrogen still sucks as a fuel, whether in internal combustion engines or fuel cells, because it is so bulky.

Scott Kenny

ACCESS: USAP

- Joined

- 15 May 2023

- Messages

- 11,628

- Reaction score

- 14,305

Well, methanol burns clear. You cannot see the flames in daylight. At all.The two fuels that are getting a lot of attention for shipping decarbonisation are methanol and ammonia, both through fuel cells. In fact, both are just means of transporting hydrogen around in a denser format - dealing with the otherwise superfluous carbon/oxygen/nitrogen is easier than trying to handle hydrogen directly.

The advocates of either option will gladly tell you why the other is sheer madness.

Whereas anhydrous ammonia is "only" nasty toxic when spilled.

In terms of which hazard I'd rather deal with, I'd rather deal with "wear an air pack around a crashed ammonia-fueled car" than "you need a thermal imager to see if the car is on fire"

Forest Green

ACCESS: Above Top Secret

- Joined

- 11 June 2019

- Messages

- 9,508

- Reaction score

- 17,402

There's mining involved with any car, you have to mine the metal to produce it, then it goes through a blast furnace etc. Hydrogen itself is also a powerful greenhouse gas if any escapes during production.the main rule of environmental technology is all technologies pollute,

Lithium batteries pollute a lot, let us face it, mining the minerals is highly polluting.

About half of the U.S. population lives in areas where air pollution levels are high enough to negatively impact public health and the environment. Emissions from gasoline and diesel vehicles—such as nitrogen oxides, hydrocarbons, and particulate matter—are a major source of this pollution. While hydrogen internal combustion engines emit lower amounts of these pollutants than gasoline and diesel engines, hydrogen-powered fuel cell electric vehicles emit none of these harmful substances—only water (H2O) and warm air. The environmental and health benefits are also seen at the source of hydrogen production if the hydrogen is derived from low- or zero-emission sources, such as solar, wind, or nuclear energy or fossil fuels with advanced emission controls and carbon sequestration

. Electric vehicles, however, require lithium-ion batteries that have issues regarding greenhouse gas emissions during the mining and processing of the raw materials needed and the disposal of the batteries at the end of their life cycle. As more and more electric vehicles are sold, the problems inherent to mining and disposal increase

The production of lithium-ion batteries that power electric vehicles results in more carbon dioxide emissions than the production of gasoline-powered cars and their disposal at the end of their life cycle is a growing environmental concern as more and more electric vehicles populate the world’s roads. About 40 percent of the climate impact from the production of lithium-ion batteries comes from the mining and processing of the minerals needed. Mining and refining of battery materials, and manufacturing of the cells, modules and battery packs requires significant amounts of energy which generate greenhouse gases emissions. China, which dominates the world’s EV battery supply chain, gets almost 60 percent of its electricity from coal—a greenhouse gas-intensive fuel.

View attachment 758480

The bidding process to renew Bogotá's bus fleet with electric buses, where 1,002 vehicles were awarded, is beginning to become a reality. The first delivery of these new units are the 172 buses received by Mueve Fontibón, the zonal operator of Transmilenio.

Environmental Impacts of Lithium-Ion Batteries - IER

The green transition is pushing electric vehicles upon the American public as it is believed that they are less greenhouse…www.instituteforenergyresearch.org

View: https://www.youtube.com/watch?v=XX1DKuS0n3Q

View attachment 758481

the point is the Colombian bus reduces emissions by passenger by being a bus and carrying lots of people and reduce the need for more batteries due to the hydrogen fuel cells.

It only carries 540 kg of hydrogen and has a range of 400km+

a EV with Lithium batteries will add lots of weight due to batteries and PM polluting just by weight

View attachment 758490

Do electric vehicles reduce air pollution?

Electric cars improve air quality compared to petrol and diesel cars, but they do not completely fix the problem.www.sustainabilitybynumbers.com

Lithium batteries can be recycled.

Li-ion Battery Recycling

Veolia battery recycling services provide safe collection and recycling of your end-of-life Li-ion batteries. We are on hand to ensure that your batteries are safely packaged, transported, recycled, and reported.

TBH though, even Sodium Ion EVs would have equal or better range than Fuel Cells and there's very little green hydrogen about.

Scott Kenny

ACCESS: USAP

- Joined

- 15 May 2023

- Messages

- 11,628

- Reaction score

- 14,305

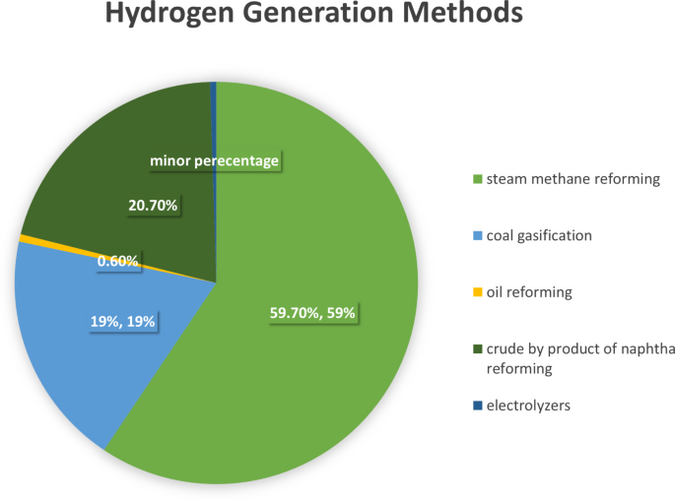

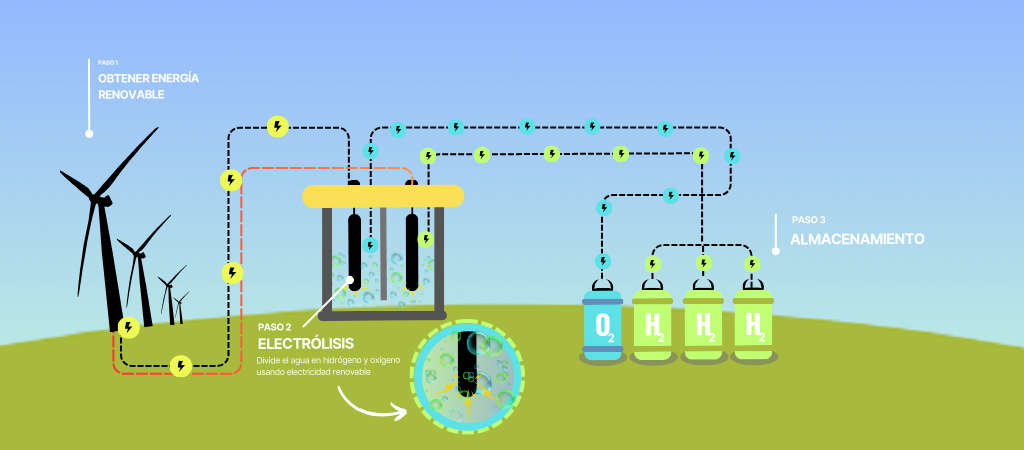

The only green way to produce hydrogen is electrolysis, powered by solar, wind, or nuclear.there's very little green hydrogen about.

Forest Green

ACCESS: Above Top Secret

- Joined

- 11 June 2019

- Messages

- 9,508

- Reaction score

- 17,402

Which is a horribly inefficienct use of electricty that's needed for other things. Ultimately it would require more solar panels, wind turbines and nuclear power stations than EV. Which all means higher electricity prices... and disposing of more nuclear waste.The only green way to produce hydrogen is electrolysis, powered by solar, wind, or nuclear.

Scott Kenny

ACCESS: USAP

- Joined

- 15 May 2023

- Messages

- 11,628

- Reaction score

- 14,305

Meh, reprocess and burn it again. Repeat until there's nothing left that is fissionable.Which is a horribly inefficienct use of electricty that's needed for other things. Ultimately it would require more solar panels, wind turbines and nuclear power stations than EV. Which all means higher electricity prices... and disposing of more nuclear waste.

F-14ATomcat

ACCESS: Secret

- Joined

- 26 May 2024

- Messages

- 454

- Reaction score

- 847

The Hydrogen-powered Audace has a GVW of 19,000 kg, capacity to transport 53 passengers and autonomy of up to 600 kilometers. The model presented has a total length of 12,000 mm, but the model will be offered in the options of total length from 11,900 mm to 12,600 mm, width of 2,480 mm and wheelbase from 6,100 mm to 6,650 mm. It has a Danfos permanent magnet synchronous motor, with a nominal power of 143 kW (peak of 235 kW) and nominal/peak torque of 495/720 Nm, two Sinosynergy G80-001 Fuel Cell batteries, of 160 kW, four type 4 Hydrogen tanks, of 700 bar, and a water cooling system, with four CATL storage battery packs, LiFeO (Lithium Iron).All that is true.

And hydrogen still sucks as a fuel, whether in internal combustion engines or fuel cells, because it is so bulky.

Ônibus a hidrogênio: Marcopolo apresenta projeto internacional - Transporte Mundial

A brasileira Marcopolo dá um importante passo em direção ao futuro da mobilidade mais limpa ao fazer parte do projeto de desenvolvimento de um ônibus rodoviário movido a células de combustível de hidrogênio. O ônibus está sendo desenvolvido em parceria com a Sinosenergy, Feichi Bus e Allenbus. O...

F-14ATomcat

ACCESS: Secret

- Joined

- 26 May 2024

- Messages

- 454

- Reaction score

- 847

Today, we have a product approved for urban vehicles that we call Marcopolo Attivi Integral, consisting of a family of 12- to 13-meter vehicles with electric propulsion and all the development work on chassis, propulsion, electrification and energy management, developed entirely by Marcopolo in Brazil.There's mining involved with any car, you have to mine the metal to produce it, then it goes through a blast furnace etc. Hydrogen itself is also a powerful greenhouse gas if any escapes during production.

Lithium batteries can be recycled.

Li-ion Battery Recycling

Veolia battery recycling services provide safe collection and recycling of your end-of-life Li-ion batteries. We are on hand to ensure that your batteries are safely packaged, transported, recycled, and reported.www.veolia.co.uk

TBH though, even Sodium Ion EVs would have equal or better range than Fuel Cells and there's very little green hydrogen about.

View attachment 758527

It is from this platform, a battery-electric vehicle with plug-in charging, that we now have the capacity to transform this existing platform into production, approved and validated, for a hydrogen vehicle. So this is the first step: from an existing platform, the tendency is for us to move towards a hydrogen solution.

In fact, this is an electric vehicle, where we have replaced a large part of the batteries with hydrogen tanks and a fuel cell, and in this way we are offering yet another solution to the market.

It is still a work in progress. We are at the beginning of the project and the embryo of this work is the reactivation of the buses that operated at EMTU, together with the operator at the time in the ABD Metropolitan Corridor. There were three buses, where Marcopolo, together with an agreement established with Embrapii, USP and FUSP, carried out an additional action (to the first contract signed between other companies) for the installation of a hydrogen reformer from ethanol – at the University of São Paulo. The buses that Marcopolo is helping to repair are part of a second contract to which we are contributing to the resumption of the hydrogen recharging station project from ethanol.

These are projects in which we are investing initially, with our own resources and, in a second phase, with some line of funding that we are seeking to accelerate all developments. Speaking of the line of larger vehicles, larger urban vehicles, we have the Marcopolo Attivi Integral platform.

….. ANOTHER PRODUCT LINE IS THE MICROBUS

RENATO FLORENCE: The Volare Microbus platform, also a Marcopolo chassis, is an all-wheel drive vehicle developed by the company and, based on this platform, we are also developing a solution for a hybrid vehicle, whose propulsion architecture is series electric.

This vehicle is electric, but does not require the use of external charging infrastructure. It is a non-plug-in car. Using a generator set with an ethanol engine, it is possible to recharge the batteries, using this on-board generation of electrical energy.

This is a work in progress, as is the biofuel from ethanol. The hybrid electric car is another line of action. In addition to the development of other solutions that go hand in hand with Euro 6 Diesel, HVO and some applications with gas engines that are also being tested by the company.

As you can see, Marcopolo has been working on a wide range of options so that we can serve the different regions and their unique characteristics of a Brazil with its very distinct regional particularities.

WHAT IS THE STATUS OF THE HYDROGEN BUS PRESENTED AT IAA 2022?

RENATO FLORENCE: Last year, Marcopolo presented the hydrogen bus, through a project structured by our subsidiary in China. This is a project involving a consortium of companies where we developed a chassis with electric propulsion and also with energy generation from the fuel cell. It is a car available on the market, approved for European standards and that can be nationalized from Marcopolo's plants in Brazil. This can be done from the moment there is a demand for this product here.

IS THE DEMAND FOR GREEN HYDROGEN GROWING IN THE SECTOR?

RENATO FLORENCE: We have been invited to participate in a series of projects, initially more academic and focused on the exploration of this fuel – which is often available from some producers. One of the major challenges for hydrogen is its production in an economically viable manner.

Today we still find values in which all the assessments of total cost, ownership and operating costs, in which the results are not yet competitive on an industrial scale, but we believe that given the advancement of all technologies we will reach a competitive cost, or rather, a competitive operating cost in relation to electric and diesel vehicles.

Hydrogen has the advantage – in relation to electric and battery vehicles – of its autonomy. This is what we hope to advance in the next periods of testing and development with this solution.

IS THE APPLICATION OF HYDROGEN TODAY MORE APPLIED TO HEAVY VEHICLES?

Hidrogênio verde é um dos pilares da transição energética para a Marcopolo - Instituto de Engenharia

Referência mundial na fabricação de carrocerias de ônibus e no desenvolvimento de soluções de eletromobilidade alinhadas aos mais modernos conceitos de sustentabilidade, a Marcopolo tem no hidrogênio verde uma de suas grandes apostas junto à transição energética. Nos últimos quatro anos, a...

Hidrógeno Verde: ¿Qué es y Para Qué Sirve?

Descubre qué es el hidrógeno verde y cómo puede revolucionar el transporte. Aprende sus beneficios, aplicaciones y su impacto sostenible.

F-14ATomcat

ACCESS: Secret

- Joined

- 26 May 2024

- Messages

- 454

- Reaction score

- 847

This threat mainly relates to the fact that exploitation is mostly carried out via lithium brine extraction and deposition in evaporation pools. The resulting concentrate is then removed for processing into lithium carbonate. Each tonne of lithium requires around 2 million litres of water to be evaporated, resulting in enormous quantities of water being lost every year and putting underground freshwater reserves in danger of salinisation by getting in contact with brine. The consequences of this “water mega-mining” are demonstrated by a fall in the water table, the salinisation of freshwater and a reduction in underground water available [2], [3]. This results in the drying up of surface water bodies and the damage to wetland ecosystems, with direct impacts on biodiversity and climate, as vast quantities of securely stored carbon are released into the atmosphere as CO2 and reduces their resilience – making local communities and Andean countries more vulnerable to the adverse effects of climate change.The only green way to produce hydrogen is electrolysis, powered by solar, wind, or nuclear.

World Water Day: The water impacts of lithium extraction - Wetlands International Europe

Today marks World Water Day, an annual event celebrating the most precious resource for people and nature. The same day, governments, including the EU, are meeting for the opening of the first UN Water Conference in nearly 50 years, during which they will discuss prevailing issues and make...

europe.wetlands.org

europe.wetlands.org

Indigenous Communities Face Water Crisis Amid Lithium Mining Boom

Indigenous Communities Face Water Crisis Amid Lithium Mining Boom

Earlier this year, the Associated Press reported on the "lithium triangle" – a region spanning Argentina, Chile, and Bolivia – where native communities sit upon an estimated trillion dollars in lithium reserves. This valuable metal is crucial for producing electric car batteries and advancing...

Scott Kenny

ACCESS: USAP

- Joined

- 15 May 2023

- Messages

- 11,628

- Reaction score

- 14,305

A passenger bus is probably the only place where hydrogen works.The Hydrogen-powered Audace has a GVW of 19,000 kg, capacity to transport 53 passengers and autonomy of up to 600 kilometers. The model presented has a total length of 12,000 mm, but the model will be offered in the options of total length from 11,900 mm to 12,600 mm, width of 2,480 mm and wheelbase from 6,100 mm to 6,650 mm. It has a Danfos permanent magnet synchronous motor, with a nominal power of 143 kW (peak of 235 kW) and nominal/peak torque of 495/720 Nm, two Sinosynergy G80-001 Fuel Cell batteries, of 160 kW, four type 4 Hydrogen tanks, of 700 bar, and a water cooling system, with four CATL storage battery packs, LiFeO (Lithium Iron).

1) relatively small load. 53 passengers as a city bus is all of 5500kg/12,000lbs "cargo" weight at full load, and a bus probably only travels at an average of 3/4 full.

2) large volume under the floor or on the roof available for hydrogen tankage.

- Joined

- 6 November 2010

- Messages

- 5,263

- Reaction score

- 5,514

A passenger bus is probably the only place where hydrogen works.

Toyota Mirai - Wikipedia

Expensive, but not insanely so like many supercars. Limited production, I admit, but on the road today. No answer to mass market needs, yet a practical, hydrogen fuel cell powered vehicle.The Mirai was unveiled at the November 2014 Los Angeles Auto Show.[9] As of November 2022, global sales totaled 21,475 units; the top-selling markets were the U.S. with 11,368 units, Japan with 7,435 and the rest of the world with 2,622.[10]

Attachments

Similar threads

-

-

Sikorsky Long-Range Hybrid-Electric VTOL Demonstrator (HEX)

- Started by VTOLicious

- Replies: 5

-

Electric and Hydrogen aeroplanes - feasibility and issues

- Started by Grey Havoc

- Replies: 586

-

NA/R - Solar Electric Spacecraft for Asteroid Belt Exploration (1970)

- Started by Graham1973

- Replies: 3

-

General Electric Mars Mission Study July 19, 1967.

- Started by Michel Van

- Replies: 4