- Joined

- 3 June 2011

- Messages

- 18,337

- Reaction score

- 12,239

Space X will no longer attempt to catch the fairing halves instead in future they will just fish them out of the water for reuse.

Elon Musk confirms that SpaceX is done trying to catch its rocket components

SpaceX has been wildly successful in just about every one of its efforts. The company was the first to make reusable rocket technology both safe …bgr.com

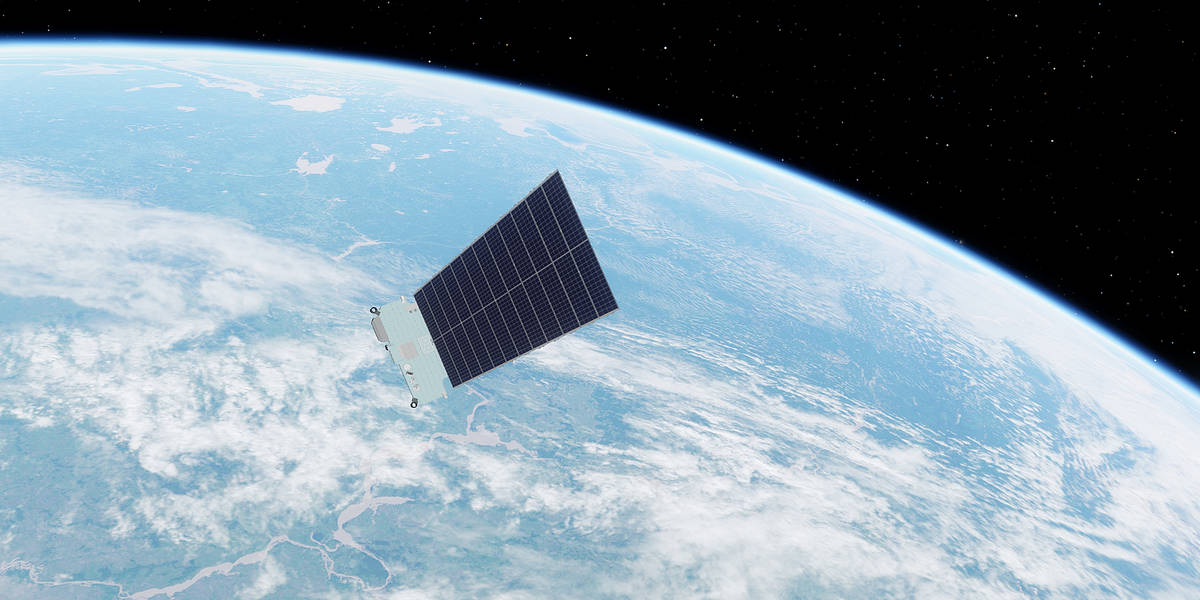

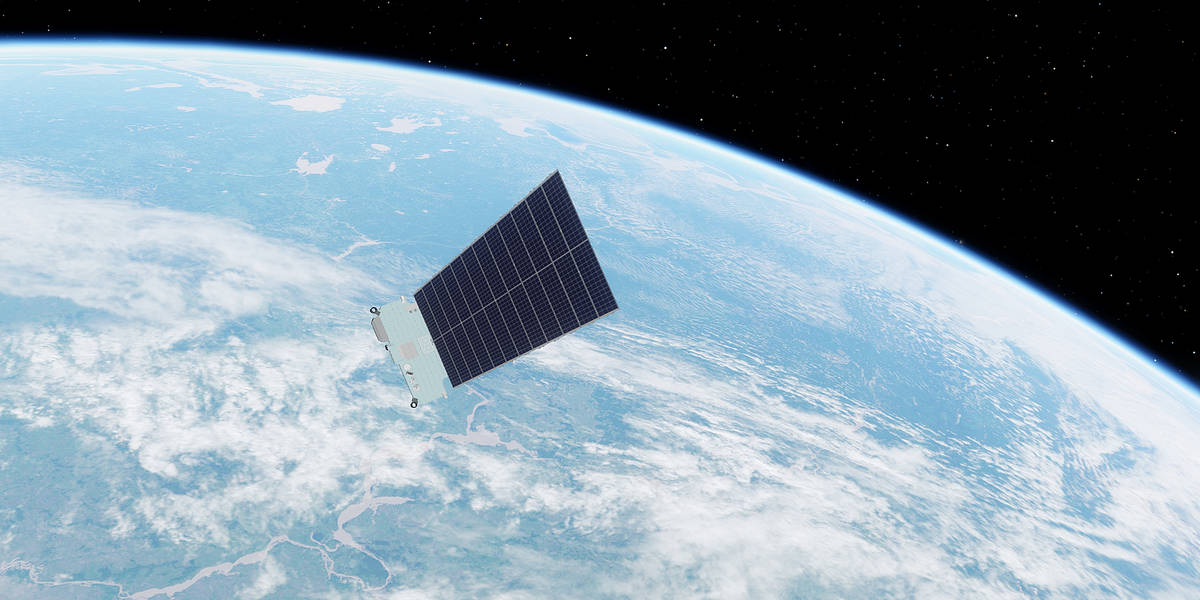

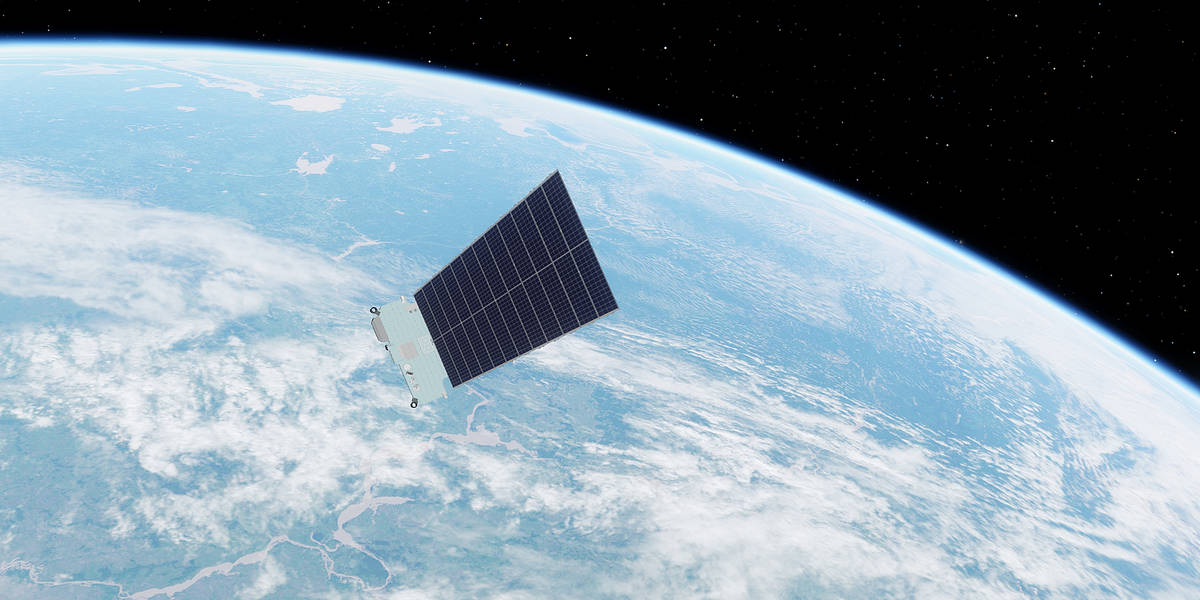

SpaceX's Starlink: Overhyped and underpowered to meet broadband needs of Rural America, say analysts

As the constellation stands anywaywww.theregister.com

One Heavy core did land successfully. Unfortunately, the Octagrabber had not yet been modified to work with a Heavy core and so it couldn’t be used to secure the booster, and rough seas later caused the booster to tip over and break. But it did at least land successfully.I think they have over a dozen used boosters in inventory, but I assume there are rare clients who still want new builds and there are some missions where the booster gets sacrificed. Also I think the core of the heavy has never been successfully landed to date. But I can't remember the last launch that was a first use. Probably just slipped my notice.

SLS is being developed according to the Zeroth Law of aerospace development (Thou Shalt Get It Right The First Time) and its corollary (Thou Shalt Not Lose The Vehicle). It becomes a feedback loop—you have to get it right the first time, so you design extremely conservatively, study it to death, and test the snot out of everything at the component level. That drives cost through the roof. When the cost is then stupendously high, you really can’t afford to lose the vehicle (Congress, shareholders, the Board of Directors, and The Public see that as a waste of money), so you get even more conservative, study things more, and do even more testing, and the cost goes still higher.You mean like the kind that takes a decade to build a "new" rocket out of existing parts and not fly? That kind of "sane" engineering?They are churning them out just to be blown up like heretics thrown in the pyre during the Middle Ages...

Did they lost faith in sane engineering?

I don't know what the hell the SLS team's excuse is but it better be a doozy given the way that SpaceX is advancing in leaps and bounds. Very difficult not to be cynical.

SLS is being developed according to the Zeroth Law of aerospace development (Thou Shalt Get It Right The First Time) and its corollary (Thou Shalt Not Lose The Vehicle). It becomes a feedback loop—you have to get it right the first time, so you design extremely conservatively, study it to death, and test the snot out of everything at the component level. That drives cost through the roof. When the cost is then stupendously high, you really can’t afford to lose the vehicle (Congress, shareholders, the Board of Directors, and The Public see that as a waste of money), so you get even more conservative, study things more, and do even more testing, and the cost goes still higher.

SpaceX is taking a completely different approach. They’re betting that a “hardware-rich” development program, even after a couple dozen failures, will in the end cost less (even including the cost of lost hardware) and go faster than the traditional approach described above.

<Snipped for brevity>

Or it's simply cheaper to refurbish them than try to recover them during launch.Space X will no longer attempt to catch the fairing halves instead in future they will just fish them out of the water for reuse.

Elon Musk confirms that SpaceX is done trying to catch its rocket components

SpaceX has been wildly successful in just about every one of its efforts. The company was the first to make reusable rocket technology both safe …bgr.com

SpaceX's Starlink: Overhyped and underpowered to meet broadband needs of Rural America, say analysts

As the constellation stands anywaywww.theregister.com

They probably handle water better than assumed.

That's about the best description for what the SLS team is doing that I've heard.SLS is being developed according to the Zeroth Law of aerospace development (Thou Shalt Get It Right The First Time) and its corollary (Thou Shalt Not Lose The Vehicle). It becomes a feedback loop—you have to get it right the first time, so you design extremely conservatively, study it to death, and test the snot out of everything at the component level. That drives cost through the roof. When the cost is then stupendously high, you really can’t afford to lose the vehicle (Congress, shareholders, the Board of Directors, and The Public see that as a waste of money), so you get even more conservative, study things more, and do even more testing, and the cost goes still higher.You mean like the kind that takes a decade to build a "new" rocket out of existing parts and not fly? That kind of "sane" engineering?They are churning them out just to be blown up like heretics thrown in the pyre during the Middle Ages...

Did they lost faith in sane engineering?

I don't know what the hell the SLS team's excuse is but it better be a doozy given the way that SpaceX is advancing in leaps and bounds. Very difficult not to be cynical.

SpaceX is taking a completely different approach. They’re betting that a “hardware-rich” development program, even after a couple dozen failures, will in the end cost less (even including the cost of lost hardware) and go faster than the traditional approach described above.

They’re able to keep the build cost down because they’ve eschewed another traditional aerospace mindset that says “use whatever large-scale equipment and cutting-edge technology it takes to build a super-optimized maximum-performance structure”. We see this all over, from small aircraft to new rockets, where all kinds of large, expensive, dedicated tools (autoclaves, jigs and fixtures, massive milling operations) and advanced techniques (friction-stir welding, automatic filament-winding, large CNC machines, etc) are used to make highly-optimized structures, and then companies try to squeeze cost out later.

SpaceX started at the other end, with little more than equipment you could find at any large construction site or well-equipped hobby garage, and tried to start building rockets. They’ve added more equipment only as they’ve determined what’s actually needed to get a good product. And even now on their prototypes, they’re pulling off-the-shelf components (Tesla motors and battery packs, for example) instead of outsourcing for brand-new dedicated items intended to be production-representative. The whole process reminds me of what any DIYer has probably experienced on a new project—you start with the tools you have, and buy more as you go along when you find out you need them.

Another factor in the “don’t lose the vehicle” mindset is that loss of the vehicle probably meant the loss of most of your data and possibly a life or three. SpaceX isn’t as worried about this—Starship prototypes are unmanned and they instrument the heck out of everything and collect all the data in real time. I’d be willing to bet a beer that a single Starship hop generates at least as much (non-video) data as the entire Saturn V flight program.

Finally, as others have pointed out, much of the data they need to get simply can’t be replicated subscale or simulated—and even if it could, the full-scale testing is probably still cheaper—plus, it’s getting them experience with manufacturing and ground handling on a vehicle this large.

i had some thought about the cost of SN

They are according Musk tweets mass around 150 short tons or 136 metric tons

mostly 304L steel that cost $1880/short tons

if we count 15 short tons for equipment, engine hydraulics and flight electronic

remain 121 short tons tank structure wings

cost estimation

121 short tons steel 304L = $253800

3 Raptors each $25 million ? = $75000000 (estimation)

1 Tesla Battery pact = $3500 dollar

x COPV tanks = $1000000 (estimation)

Flight electronic = $1000000 (estimation)

A SN Could cost around $77 million

i had some thought about the cost of SN

They are according Musk tweets mass around 150 short tons or 136 metric tons

mostly 304L steel that cost $1880/short tons

if we count 15 short tons for equipment, engine hydraulics and flight electronic

remain 121 short tons tank structure wings

cost estimation

121 short tons steel 304L = $253800

3 Raptors each $25 million ? = $75000000 (estimation)

1 Tesla Battery pact = $3500 dollar

x COPV tanks = $1000000 (estimation)

Flight electronic = $1000000 (estimation)

A SN Could cost around $77 million

i had no info on price of Raptor, they really cost only $2 million ?No. Almost all of that price is for the Raptor, and we know that they are already cheaper than $2M. SpaceX has never paid anywhere near $25M for any engine they have ever flown.

spacenews.com

spacenews.com

i had no info on price of Raptor, they really cost only $2 million ?No. Almost all of that price is for the Raptor, and we know that they are already cheaper than $2M. SpaceX has never paid anywhere near $25M for any engine they have ever flown.

any source i can check ?

Though that can end up being a major fallacy in itself.They chase cost reduction as the primary goal.

Where they're both the manufacturer and the customer they should be able to self-regulate.Though that can end up being a major fallacy in itself.They chase cost reduction as the primary goal.

Well it does allow for preservation of test material to be a very secondary goal, which seems to be working to date just by the measuring stick of Phalcon 9. I honestly thought Elon would spectacularly fail in the Falcon 1 days, and even when he made Falcon 9 cheaper than most comparable boosters as a throw away, I expected failure in recovering boosters. But I guess having a mass production point of view and a lot of money is better than a Persian cat and Agent #2 with a piranha pool...Though that can end up being a major fallacy in itself.They chase cost reduction as the primary goal.

SpaceX crews are hard at work following two cryo tests, meaning Raptors could be installed within days! Progress on the orbital pad is in overdrive, with the launch tower taking shape and the first GSE tank in place. Meanwhile BN1 is being scrapped for BN2, which will fly!

Aiming to launch next week

'Should' being the operative word.Where they're both the manufacturer and the customer they should be able to self-regulate.

www.forbes.com

www.forbes.com

Elon Musk's SpaceX Wins Contract To Develop Spacecraft To Land Astronauts on the Moon - Slashdot

NASA on Friday selected SpaceX to build spacecraft that would land astronauts on the moon for the first time since the last Apollo mission, according to a source selection document obtained by The Washington Post. From the report: The contract marks another major victory for the hard-charging...science.slashdot.org

A sole source award will be politically hugely unpopular in some quarters I am guessing. NASA maybe looking for more budget so they can bring a competitor onboard.

Elon Musk's SpaceX Wins Contract To Develop Spacecraft To Land Astronauts on the Moon - Slashdot

NASA on Friday selected SpaceX to build spacecraft that would land astronauts on the moon for the first time since the last Apollo mission, according to a source selection document obtained by The Washington Post. From the report: The contract marks another major victory for the hard-charging...science.slashdot.org