a - Probable tomorrows - how science and technology will transform our lives in the next twenty years. Marvin Cetron, Owen Davies

SPACECAST 2020, Volume 1 - Global reach-white papers - Spacelift: Suborbital, Earth to Orbit, and On Orbit – p.163 – 221 – 1994

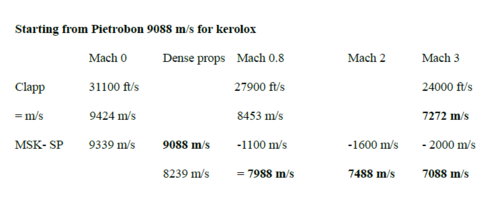

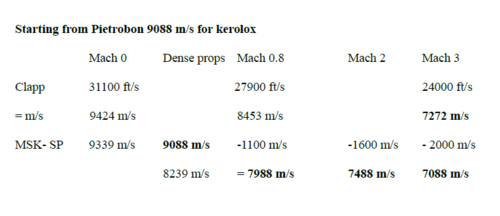

«The system is nothing if not cheap. Clapp's target is to build a fleet of five to ten spacecraft, which could fly one Black Horse mission per day. The squadron's total operating budget would be around $100 million per year, roughly the same as that of the SR-71 Blackbird high altitude reconnaissance aircraft. That translates to a launch cost of only $500 per pound of payload, or $1,100 per kilogram; with a larger fleet, the price could fall from there.

One way to pare the cost still further is with an imaginative two-ship mission. One vehicle carries the cargo, the other flies with only its crew. It turns out that the deadheading spacecraft arrives in space with 20,000 pounds (9,100 kg) of unused fuel. So pump the fuel into the cargo carrier and fly the companion vehicle back to Earth. The second Black Horse can then proceed to orbit with a useful load of 12,000 pounds (nearly 5,500 kg), plus its crew. If the launch cost of one vehicle carrying its standard payload comes to $500 per pound ($1,100 per kg), the cost for the combined mission drops to less than $85 per pound ($187 per kg)! And at that price, many missions become possible.»

b - The Flock Booster Architecture – Low Cost Access to LEO via Sustained Fueling

Alan Goff,

Novatia, Folsom, CA

For a mass budget of 500 kg per passenger, a 30-ton payload supports 60 paying passengers. At $50,000 a ticket, revenue per flight is $3M, and amortized launch costs of $1M yields a net income of $2M/flight. Assuming one flight/day, 5 days/week, 40 weeks/year, it would take 15 months to exhaust a market of 15,000 customers, generating enough income to pay for the production costs of the rocket plane and perhaps the passenger compartment.

A criticism of the cost model is that turning around a reusable rocket is a time-consuming manpower intensive operation, and doing dozens at once would scale badly. While true for current rockets designed for performance, Flock rocket planes can be designed for low maintenance and fast turnaround. The specific goal of achieving airline like operations is to control these costs. The estimates used in this cost model are engineering judgments based on current technology and existing systems.

c - Economics of Separated Ascent Stage Launch Vehicles

Chris Y. Taylor

Jupiter Research and Development, Houston, TX 77043

Developed structure-payload mass ratio,

rD, is the mass of new vehicle structure that must be developed divided by the payload mass. One way to reduce the developed structure-payload mass ratio is to reduce the overall vehicle structure-payload mass ratio,

r. If a smaller launch vehicle is built, then it seems natural that it would cost less. If the developed vehicle mass for is reduced by reducing the total vehicle mass for a fixed payload mass, then certain recurring launch vehicle costs would be reduced as well. Unfortunately, reducing vehicle structure-payload mass ratio usually requires saving vehicle weight or improving vehicle performance which increases the vehicle development structure cost. For a launch vehicle design, there will be a vehicle structure-payload mass ratio that provides a minimum development cost. Cost savings resulting from a vehicle smaller than this optimum structure payload mass ratio would be more than offset by increased costs incurred in the more difficult development program.

Fortunately there are other ways to reduce the developed structure-payload mass ratio without having to reduce vehicle’s structure-payload mass ratio. Developed structure-payload mass ratio is only equal to structure-payload mass ratio if the development program must develop the entire vehicle. If not all of the launch vehicle has to be developed, then not all of the vehicle mass has to be counted as part of the developed structure-payload mass ratio.

For example, if a good existing upper stage exists then that stage might be combined with a newly developed lower stage. Only the mass of the new lower stage would need to be counted when calculating the developed structure payload mass ratio. While this “new launch vehicle” would really only be a partially new vehicle, there is no advantage to having a new upper stage for the sake of newness if the replacement of the old one cannot be justified economically. Similarly, existing solid rocket motors might be used as solid rocket boosters for an otherwise new launch system in order to reduce the size of the development program. In addition to reusing old stages to reduce the developed structure-payload mass ratio, smaller vehicle components can be reused as well. Engines, structure, electronics, or other parts that have been proven to have good performance in past launch vehicles might be reused in future ones with the development program focusing only on portions of the vehicle where the cost of a new component can be justified by its increased performance. A launch vehicle that is designed in this evolutionary way could have a noticeably lower amortized development cost. There would still be some new development effort associated with the older parts to integrate them into the new vehicle and so the exact value of the developed structure-payload mass ratio might not be clear, but it would obviously be lower than the full value of the vehicle’s structure-payload mass ratio.

Even if the entire vehicle and its components are the result of a new development effort, the developed structurepayload mass ratio might still be lower than the vehicle’s structure-payload mass ratio if it uses identical stages. The simplest case of this is a bimese rocket where the booster and orbiter stages are identical. In the case of a bimese the developed structure-payload mass ratio would be half of the structure-payload mass ratio since only one of the stages would need to be developed and the production quantity for the stage doubled to provide the other half of the assembled vehicle. Unfortunately a bimese rocket suffers from staging inefficiencies that drive the total vehicle mass up above a conventionally sized rocket and cancels out the advantage of having the developed structure payload mass ratio be based on only half of the vehicle’s total mass. The hypothetical launch vehicle with a structure-payload mass ratio of 2 used to calculate current launch costs in Section III could be achieved as a two stage rocket and an average Isp of 380s if the lower stage is allowed to be 4.6 times larger than the upper stage. If both stages are forced to be the same size in order to achieve a bimese configuration, the structure-payload mass ratio increases to 4 and the developed structure-payload mass ratio still remains 2!

Trimese launch vehicles, composed of three identical major components with two components serving as boosters and one as an orbiter, were studied in the late 1960’s and early 1970’s and would have a developed structure-payload mass ratio that was only one third of the structure-payload mass ratio. The staging inefficiencies are not as bad with this design and using the same assumptions described above a trimese launch vehicle would have a structure-payload mass ratio of about 2.3 and a developed structure-payload mass ratio of about 0.8. The greater complexity of having one stage that could function as both a booster and orbiter would drive up the vehicle development structure cost, but this “back of the napkin” analysis suggests that a trimese configuration might still be a viable candidate for a low-cost next generation launch vehicle based on its low developed structure-payload mass ratio.

If amortized development cost can be reduced by using a trimese design, then it is logical to ask if using even larger numbers of identical stages might result in even greater savings. Ed Keith proposed12 an Asparagus-Stalk Booster composed of seven identical units that crossfeed propellant and are dropped in pairs as they are emptied. Using pressure fed rockets with an Isp of only 290s, this concept was project to have a structure-payload mass ratio of about 3.8 but a developed structure-payload mass ratio of 0.54. With the development of modular micro-electro mechanical rockets13, perhaps a launch vehicle could be constructed of thousands of identical subcomponents that detach when no longer needed. As the number of identical clustered stages in the vehicle increases, however, additional development problems occur that increase the developed structure cost and may wind up actually increasing the amortized development cost while the developed structure-payload mass ratio declines. This increased developed structure cost comes from the increasing technical challenge of accounting for the interactions between a large number of identical components and designing one stage that can function in any location in the vehicle despite the differences in the structural, aerodynamic, thermodynamic, and acoustic environments. These interaction problems would be reduced or eliminated, however, if the identical components that comprised the launch system could be physically separated from each other instead of clustered together. This is not impossible if a separated ascent stage space launch system is used, as in FLOC or Black Horse.

A separated ascent stage launch system is one where multiple vehicles launch and ascend separately, but cooperate through either aerial refueling or momentum transfer to help one of the vehicles attain orbit. Perhaps the earliest proposed example of a separated ascent stage launch vehicle is a variation of the Black Horse rocketplane. In addition to the normal mode of operation, a “speculative operational mode” was also proposed where the payload of the rocketplane could by increased by launching two rocketplanes simultaneously on a suborbital, exoatmospheric trajectory. Once out of the atmosphere, the rocketplanes would rendezvous and one would extend a refueling boom to the other and transfer its remaining propellant. The empty rockeplane would return to earth while the refueled rocketplane reignited its engines and continued to orbit.

Another example of a separated ascent stage launch system is the family of FLOC concepts developed by Alan Goff at Novatia Labs. The original FLOC space launch concept involved the simultaneous launching of a number of identical, reusable launch vehicles configured in a bimese arrangement. The bimese stages would crossfeed propellant and the booster stage would return to Earth when empty. The remaining single upper stages would pair up, dock with each other, and continue as before until the next set of boosters was empty. The remaining stages would continue this process of pairing up and crossfeeding propellant until only one upper stage was left with enough velocity and fuel to reach orbit.

The original baseline FLOC design used to illustrate the concept was based on a reusable 400 ton GLOW rocketplane with an Isp of 372 and a structure mass fraction of 29%. This structure mass fraction was a WAG† made by Novatia based on the Boeing 747’s dry mass fraction. With a maximum payload in the 32 unit flock configuration (31 boosters and 1 orbiter) of 178 tons this system would have an overall structure-payload mass ratio of 20.9 but a developed structure-payload mass ratio of only 0.65. This developed structure-payload mass ratio is only slightly better than the trimese configuration described above, but it is accomplished with 7s less of Isp and a structure mass fraction approximately three times as large. If the technical hurdles of mid-flight refueling can be overcome, then the FLOC vehicle would present a much easier design challenge than a reusable trimese vehicle.

The ability to increase the payload capacity of a FLOC launch system by doubling the flock size and adding another binary staging event to the trajectory gives it even greater insensitivity to weight growth than a conventional multistage rocket. If unexpected weight growth during vehicle development reduced the payload of a conventional launch vehicle below mission requirements then an expensive redesign effort would be required. With a FLOC launch system, the payload could be carried by the next highest flock size. Increasing the number of rockeplanes in the flock would increase hardware and operations cost, and require a redesign of the trajectory but it would not require the development of a new vehicle. It would not be nearly as easy to add a new lower stage to a conventional launch vehicle. The ability of the FLOC concept to change the number of binary stagings and the size of the flock to accommodate a wide variety of payload masses potentially allows the amortized development cost to be reduced even further by increasing the number of launches conducted. A twenty ton payload could be launched with an eight unit flock one day, and the next mission might use a thirty-two unit flock to launch a two-hundred ton payload. Launched singly or in pairs, the FLOC rocketplanes could also perform suborbital missions such as space tourism rides or micro-gravity experiments. By allowing one vehicle design to economically perform a wide variety of space launch missions the flight rate would be increased, with a corresponding improvement in its amortization factor. This capability also provides the opportunity to start with easier missions and build the FLOC fleet into a progressively more capable system as additional rocketplanes are acquired and the binary staging maneuver is perfected.

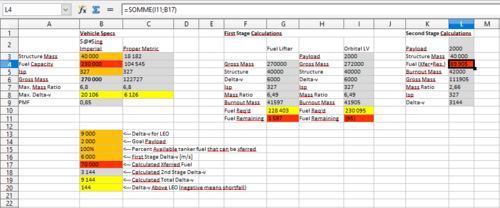

Rocket Economic Analysis

The FLOC vehicle analyzed in this section is a 400 ton rocketplane composed of 116 tons of structure, 71 tons of propellant, and 213 tons available for either payload or additional propellant. The configuration analyzed in this section will be the 32 unit flock launching its maximum payload of 178 tons to low Earth orbit. This configuration has a structure-payload mass ratio of 20.9 and a developed structure-payload mass ratio of 0.65. Despite the potential for the FLOC to increase the amortization factor with a wide range of payload capability, the amortization factor,

a, used for this analysis will remain. Assuming the high structure mass fraction of the vehicle allows an inexpensive development program, as Novatia hopes, but that the vehicle development program cost is still within the historic range for rocket launch vehicles a developed structure cost of $20,000 per pound was initially chosen for the cost analysis.

This gives an amortized development cost per pound of payload delivered to orbit of (0.65 lb./lb.* $20,000/lb)/27, or $481 per pound of payload.

This is a considerable reduction from the $1,500 to $9,000 per pound specific amortized development cost estimated for current launch vehicles in Section II.

Assuming that the vehicle hardware costs are also at the low end of historic values for rocket launch vehicles at $1000 per pound of structure and that the reusable rocketplanes are worn out at a rate of 1% per flight, vehicle hardware costs were estimated to be $209 per pound of payload. The specific cost of risk for FLOC is more difficult to estimate than for conventional launch vehicles because a launch vehicle failure would not destroy the payload if it occurs on a vehicle that is not carrying the payload and because additional pairs of vehicles might be launched so that even if one had to drop out of the flock because of a malfunction the launch might still be carried out using a spare vehicle. Assuming a cargo value of $10,000 per pound and a chance of a vehicle failure during the launch of

1%, the cost of risk was estimated to be about $20 per pound of payload. This low probability of failure assumes that bringing two partially-fueled rocket vehicles together and docking them during ascent can be done routinely. If the binary staging maneuvers cannot be made safe enough to be carried out routinely then the FLOC concept will fail for reasons other than just economics. Propellant costs were estimated at about $4 per pound of payload, which is so small as to be within the error of other cost estimates in this section. Using a labor cost of $100 per hour, the specific labor cost would be $(2090*

L) per pound of payload where

L is labor intensity in units of hours per pound of structure. The lowest current launch vehicle labor intensities are around 1 hr/lb, which would give a huge specific labor cost for FLOC of $2090 per pound of payload because of the overall high structure-payload mass ratio of the 32 unit flock. One of the primary goals Novatia had for FLOC was to improve vehicle operations cost at the expense of a higher structure mass fraction. Assuming that in using the relatively high (for a rocket) structure mass fraction of 29%, Novatia succeeded in reducing the required labor intensity by an order of magnitude the resulting specific operations cost would be $209 per pound of payload.

The result of this rocket-based cost estimate, summarized in Table 4, shows that a cost to LEO of less than $1000 per pound of payload is probably achievable with FLOC if you neglect the cost of developing and demonstrating in-flight rocket refueling capability. This analysis also shows that the goal of radically reducing operations cost with a more robustly designed vehicle must be at least partially achieved to reach this. If operations labor intensity cannot be reduced below current best practices for space launch vehicles then the high structurepayload mass ratio of the concept will cause unacceptably high operation costs to overshadow any amortized development cost savings the system achieves.

Plane Economic Analysis

There is a shortage of historical data for estimating the developed structure cost of rocketplanes. The X-15 program cost $676 per pound of vehicle structure in then-year dollars, which converts to approximately $4,300/lb. in current year dollars. Based on data from

http://www.astronautix.com, Scaled Composite’s SpaceShip One cost approximately $9,500 per pound of the rocketplane’s structure mass. The X-15 data is without the engine development cost, however the baseline FLOC design was sized for use with an existing engine design. In the future, information from the X-37 program may provide additional useful cost data. Using the higher example of $9,500/lb. and the amortization factor of 27, amortized development cost was estimated at $229 per pound of payload delivered to LEO.

Using a typical aircraft hardware cost estimate of $500 per pound of structure, the specific cost of hardware is estimated at $104/lb. Using high-end estimates of supersonic aircraft labor intensity of 0.01 hrs/lb. provides an operations cost of only $21/lb. Propellant and risk cost estimates were left the same in both rocket and plane cost estimate methods. The result of this airplane-based cost estimate, summarized in Table 5, shows a cost of less than $400 per pound of payload is probably achievable if you neglect the cost of developing and demonstrating in-flight rocket refueling capability. The key unknown factors that might alter this cost estimate are the amortization factor, which might be much higher than considering the versatility of the design, and the fraction of the vehicle expended per flight, which might be much lower considering the airplane-like structural mass fraction of the vehicle. If both of these unknowns were more favorable than the conservative estimates used in this analysis then specific costs around $100/lb. to LEO might be achievable with the baseline FLOC launch system in a 32 unit configuration.

The disparity between these two cost estimates brings up the question of whether a FLOC rocketplane would be more like a rocket or more like a plane in cost. FLOC would need to be capable of space operations and reentry, which are not airplane-like features. On the other hand in terms of structural mass fraction the FLOC baseline vehicle is closer to an airplane than a rocket, and might allow airplane-like design and manufacturing techniques to be used as Novatia hopes.

The proposed Black Horse rocketplane-to-rocketplane propellant transfer was to be done with a refueling boom extended between the rocketplanes during about a six-minute exo-atmospheric portion of their suborbital flight. With the propellant transfer expected to take about two minutes, that left approximately four minutes to conduct an orbital rendezvous between two cooperative spacecraft traveling on nearly parallel trajectories in the same direction. This is a much easier task than the rendezvous with a non-cooperative target headed in the opposite direction that anti-ballistic missile missions require.